A method and system for preventing the gun from being lifted and judging the sealing state of the refueling device

A refueling device and state technology, which is applied in distribution devices, transportation and packaging, special distribution devices, etc., can solve the problems of the refueling machine jumping, cheating, and the sealing state of the refueling device cannot be found in time, so as to prevent the gun from jumping. word problem, the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0035] According to one embodiment of the present invention, further comprising, during the pre-refueling period, if the encoder 2 continuously transmits a first pulse signal, it is determined that the refueling device seal is abnormal.

[0036] According to one embodiment of the present invention, further comprising, if the difference between the last gun hanging time and the current gun lifting time is greater than 0.5h, the compression threshold is selected, if the difference between the last gun hanging time and the current gun lifting time is less than 0.5h, the expansion threshold is selected to be set; the suppression threshold is set to 0.3L, and the expansion threshold is set to 0.05L.

[0037] According to one embodiment of the present invention, the length of time during pre-refueling is set to 0.2s to 1s.

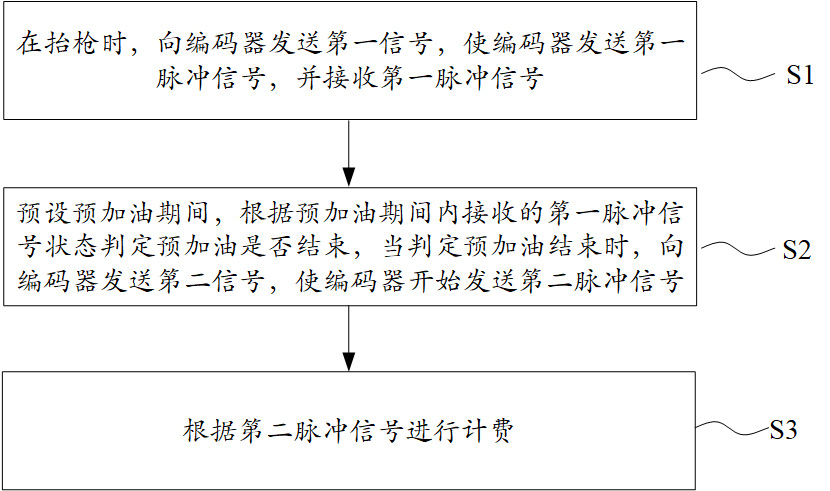

[0038] Figure 2 Schematic diagram of the process structure of the method to prevent the gun from being lifted and the method of detecting oil leakage in the refuel...

Embodiment 1

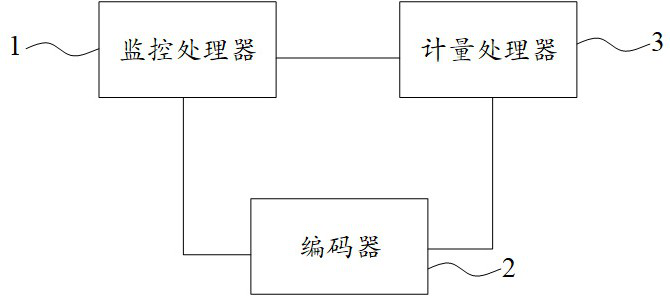

[0046] Embodiment 1, the monitoring processor receives a refueling gun gun signal, Calculate the time difference between the last gun hanging time and the time of the gun lifting is 1.5h, wherein the set time difference is 1h, the setting suppression threshold is 0.3L, and the expansion threshold is set to 0.03L, the monitoring processor selects the suppression threshold 0.3L for pre-refueling, the monitoring processor sends the first signal to the encoder, so that the encoder only sends the first pulse signal to the monitoring processor, and the length of the pre-refueling time is set to 0.5s, within 0.5s, if the first pulse signal is not received, it is judged to be the end of pre-refueling, if the received first pulse signal is from yes to none, it is judged to be the end of pre-refueling, if the encoder continues to send the first pulse signal When the monitoring processor determines that the pre-refueling is over, calculate the amount of pre-refueling, if the amount of pre-re...

Embodiment 2

[0047]Example 2, the monitoring processor receives a refueling gun gun signal, calculate the time difference between the last hanging time and the current gun lifting time is 20min, wherein, Set the time difference of 0.5h, set the suppression threshold of 0.5L, set the expansion threshold of 0.05L, then the monitoring processor selects the pressure threshold of 0.05L for pre-refueling, the monitoring processor sends the first signal to the encoder, so that the encoder only sends the first pulse signal to the monitoring processor, and the length of the pre-refueling time is set to 2s, within 2s, if the first pulse signal is not received, it is judged to be the end of pre-refueling, if the first pulse signal received is from yes to none, it is judged to be the end of pre-refueling, if the encoder continues to send the first pulse signal, it is determined that the refueling device is sealed abnormally, and the alarm prompt is carried out When the monitoring processor determines that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com