Atomizing dust-settling device capable of spraying in curtain shape

A dust suppressor and curtain-like technology, which is applied in the field of atomizing dust suppressors, can solve the problems of nozzle blockage, difficult maintenance, high cost of use and maintenance, and achieve the effects of eliminating easy blockage, low cost of use, and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

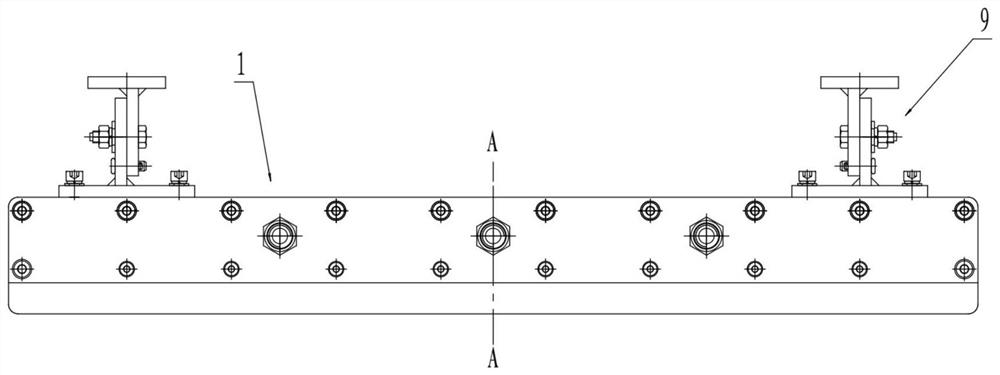

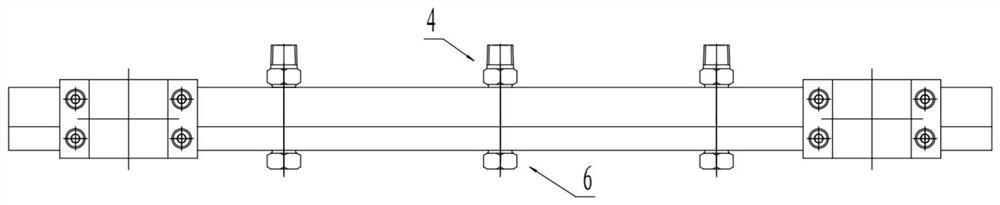

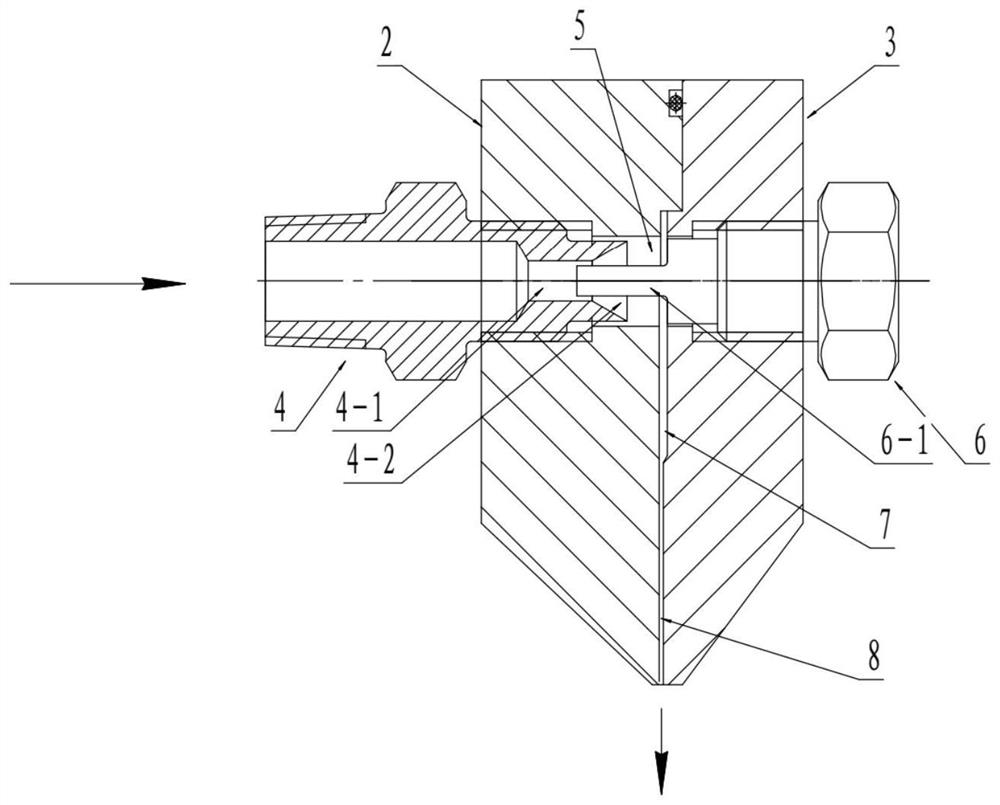

[0023] see Figure 1-Figure 3 , the present invention includes a box body 1, the shape of the box body is plate-shaped, and a chamber is arranged in the box body. The top of the box body is provided with two sets of installation connectors 9 for installing the box body. The box body includes a first large side wall 2 and a second side wall large surface 3 . The chambers include a nozzle chamber 5 , a gap chamber 7 and a slot chamber 8 . The nozzle chamber is connected to the gap chamber, and the gap chamber is connected to the slit chamber. The width of the gap chamber is much smaller than that of the nozzle chamber, and the width of the slit chamber is smaller than that of the gap chamber. The bottom surface of the slit chamber is a spray slit. The width of the spray slit is 0.1-0.3 mm. The water mist is sprayed out from the spray slit to form a curtain. Several water jet nozzles 4 are arranged side by side on the first large side wall of the box. The water jet nozzles ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com