Spraying system capable of quickly reducing heat stress reaction of dairy cow

A sprinkler system and heat stress technology, which is applied in the field of animal husbandry, can solve the problems of unfavorable cow heat stress response, high spray water hardness, and poor cooling effect, so as to reduce the heat stress response of dairy cows and reduce heat stress Exciting reaction, increase the effect of cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

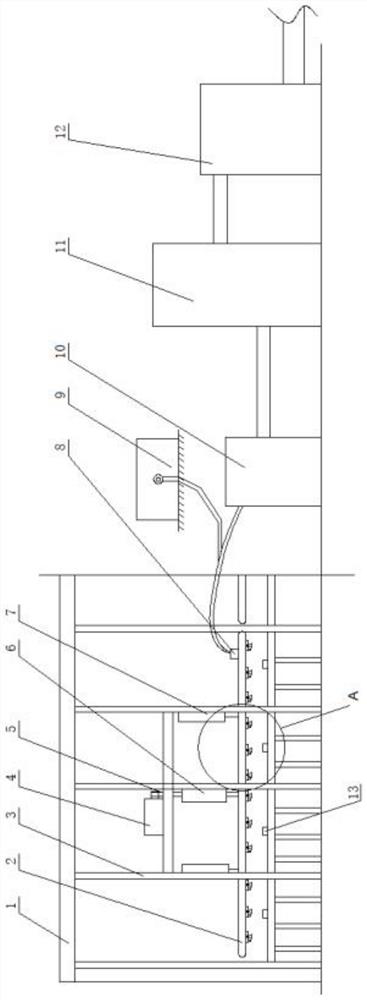

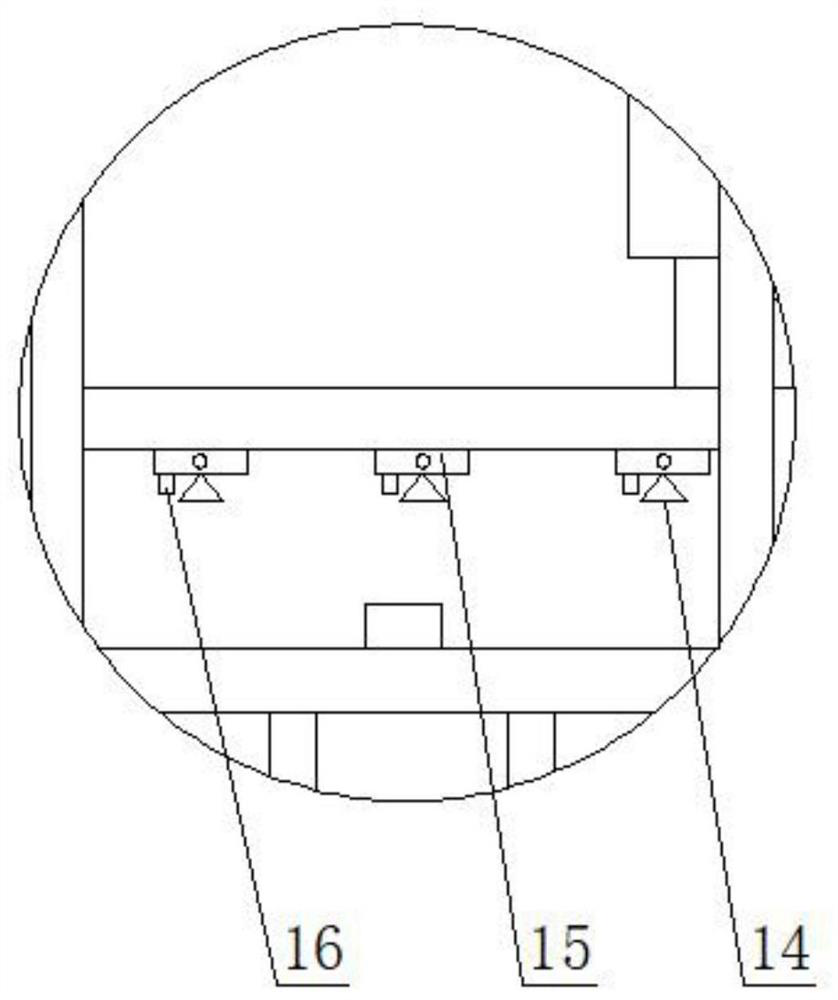

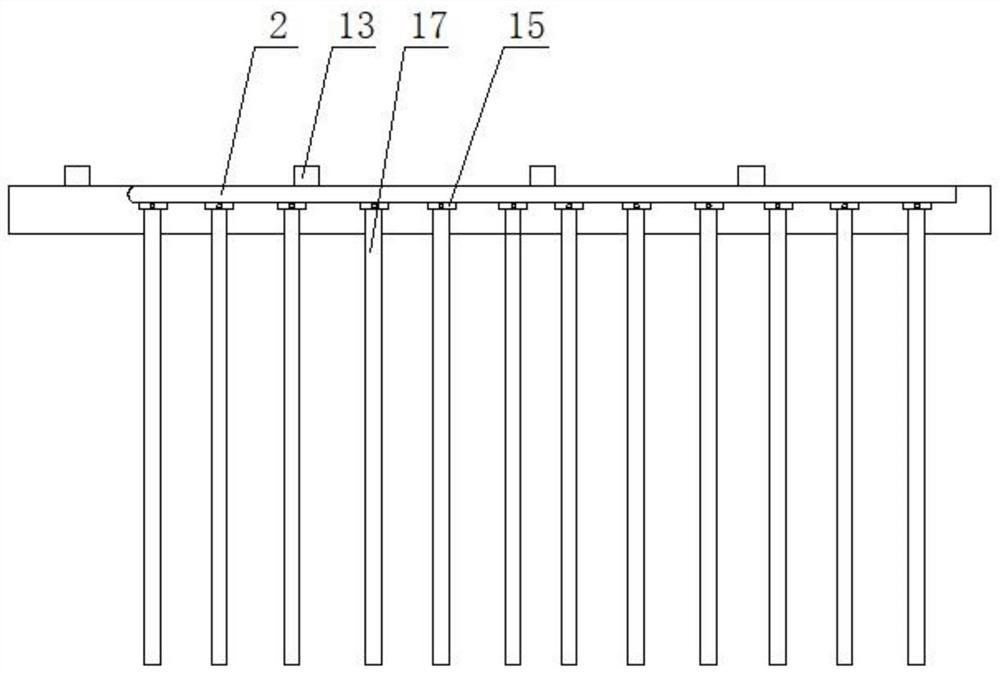

[0035] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

[0036] The present invention provides a spray system that can quickly reduce the heat stress response of dairy cows. The overall innovation of this system includes the following parts:

[0037] 1. In terms of the structure of the sprinkler system in the overall barn: convert the existing form of fan-guided water mist into a form of self-adjusting spray. The cooling water is directly atomized and then sprayed to improve the cooling efficiency and play a role in rapid cooling.

[0038] 2. In terms of the sensing of the spraying system: the existing cowshed uses infrared sensing to check whether the cattle are in the spraying position. The invention adopts the dual detection method of infrared and water mist detector, the infrared sensor is directly below the nozzle rod, and can respectively sense whether the cattle are in the spraying position, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com