A desulfurization method utilizing white clay

The technology of white mud and desulfurization agent is applied in the field of flue gas desulfurization, which can solve the problems of difficult maintenance and high requirements for operation control, and achieve the effects of improving dissociation efficiency, significant economic benefits, and good environmental and social benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

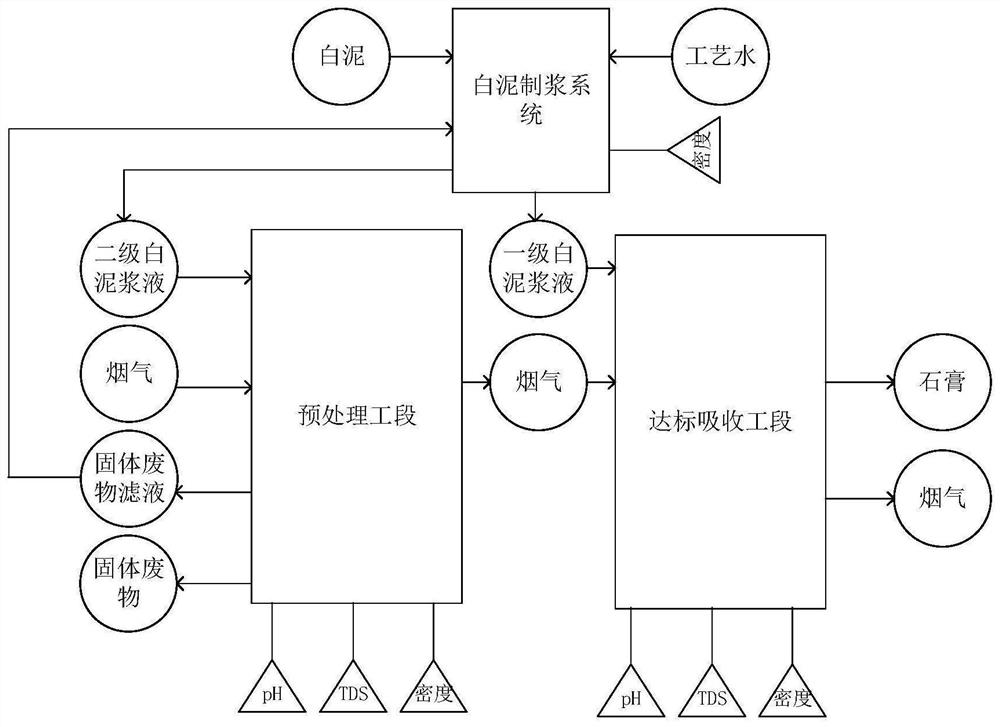

Embodiment 1

[0059] A method of completely using white mud desulfurization, including the following steps, within a time span of 1 hour, when the load of 330MW unit is 80%, the volume flow rate of raw flue gas in the pretreatment section is 1,000,000m 3 / h, its SO 2 Mass concentration 1500mg / m 3 , while adding 0.3t of white mud to prepare the white mud slurry into the pretreatment tower, SO 2 Mass concentration reduced to 1300mg / m 3 Control the pH in the pretreatment tower to fluctuate between 2.5-2.6, and the total dissolved solids to be within 75g / L. During this period, the slurry will circulate and oxidize to produce about 0.5t of solid waste including gypsum; the flue gas will enter the standard absorption section after passing through the demister , add 1.5t to prepare the white mud slurry and pass it into the absorption tower, use an oxidation fan to carry out forced oxidation, control the pH fluctuation in the absorption tower between 5.3-5.4, the total dissolved solids are within...

Embodiment 2

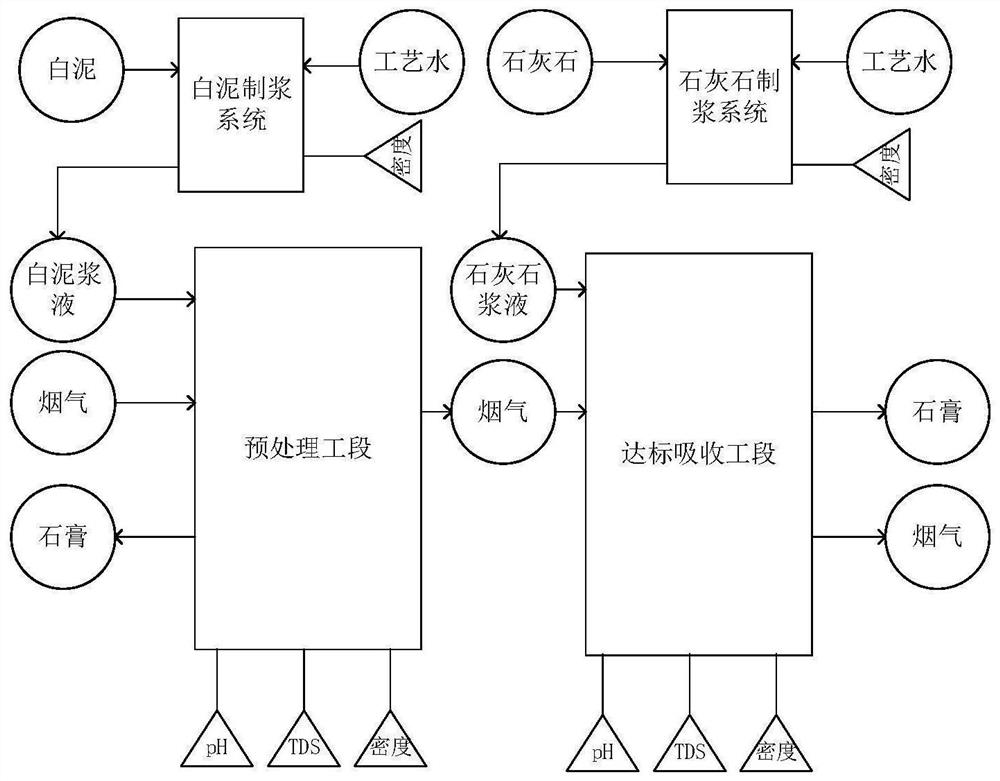

[0061]A method for partially using lime mud desulfurization, including the following steps, within a time span of 1 hour, when the load of 330MW unit is 80%, the volume flow rate of raw flue gas in the pretreatment section is 1,000,000m 3 / h, its SO 2 Mass concentration 1500mg / m 3 , and at the same time add 0.8t to prepare the white mud slurry and pass it into the pretreatment tower, use the oxidation fan to carry out forced oxidation, SO 2 Mass concentration reduced to 1000mg / m 3 Control the pH in the pretreatment tower to fluctuate between 4.2-4.4, and the total dissolved solids are within 80g / L, which meets the pretreatment requirements. During this period, the slurry circulation is forced to oxidize to produce about 1.3t of low-grade gypsum; the flue gas enters after passing through the demister In the up-to-standard absorption section, add 2.5t of limestone powder to prepare limestone slurry and pass it into the absorption tower, use an oxidation fan for forced oxidatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com