System for manufacturing of three dimensional objects

A technology of three-dimensional objects and subsystems, which is applied in the direction of manufacturing tools, additive manufacturing, and improvement of process efficiency. The effect on the lifetime of reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

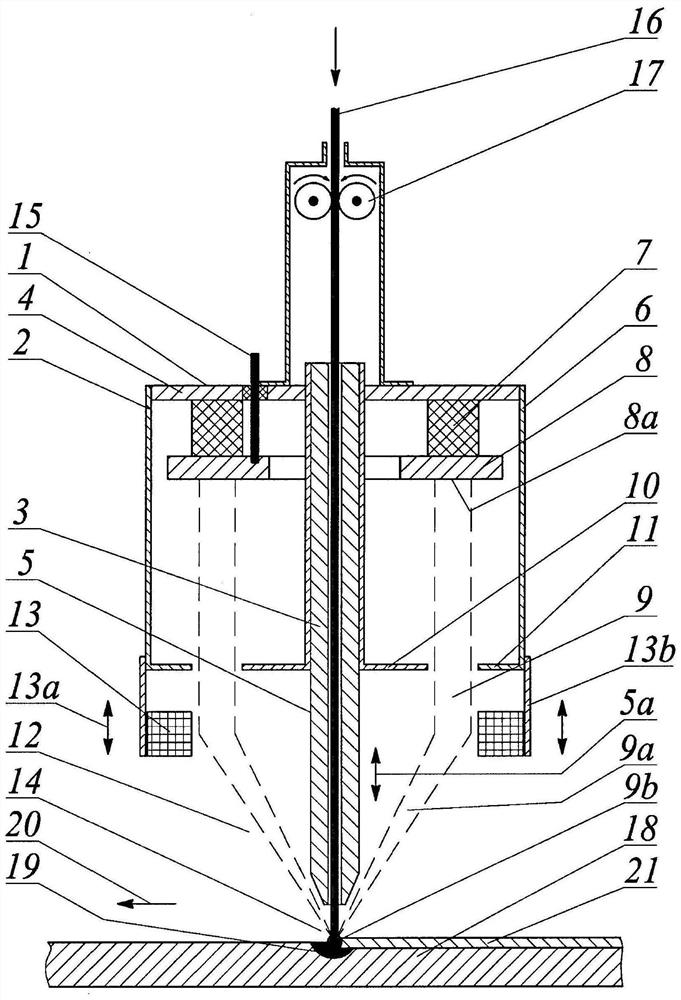

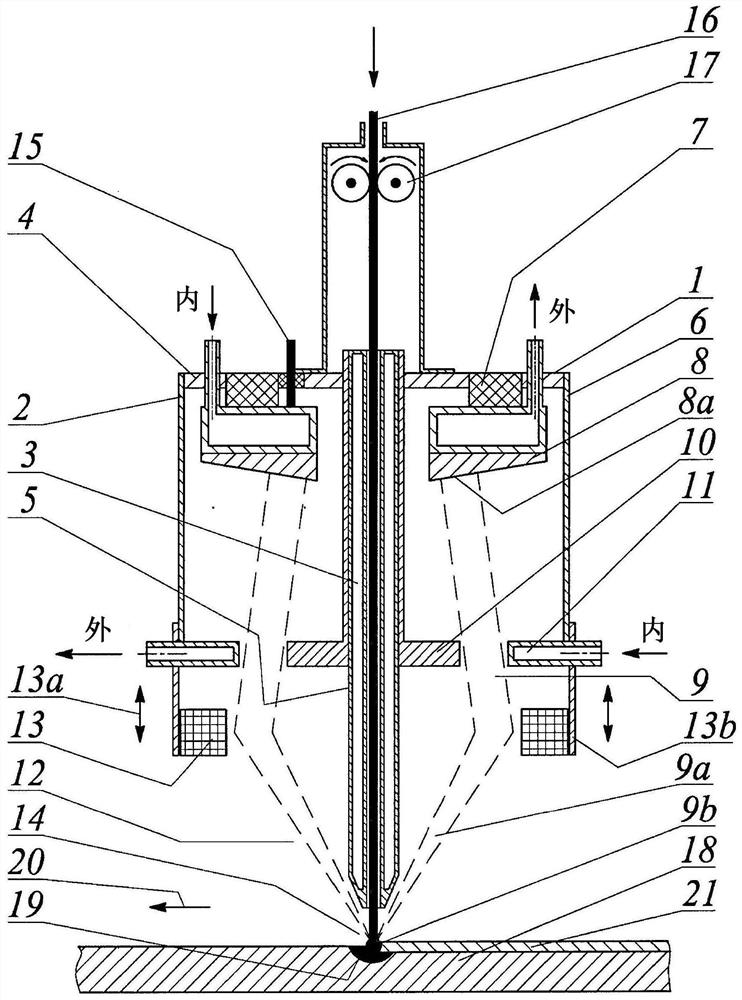

[0063] The present invention is illustrated by the following drawings, wherein the accompanying drawings ( Figure 1-Figure 3 ) of the claimed system have the same numbering.

[0064] A general view of a functional component such as figure 1 Shown, this assembly is the main element of a system for fabricating three-dimensional objects, in a design with a circular cathode whose emitting surface is flat and perpendicular to the axis of the electron beam gun.

[0065] The functional assembly 1 consists of a gas-discharge electron beam gun 2 and a feed guide 3 which together pass the body of the feed guide 5 rigidly fixed coaxially with the base flange The center hole of the base flange 4 of the electron gun is combined in a single assembly unit. The gun body 6 and the entire high-voltage circular insulator 7 are firmly attached to the base flange 4 of the electron beam gun, through which a ring-shaped cathode 8 is mounted between two ring-shaped anode electrodes arranged coaxia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com