Spark plug and engine

A technology of spark plugs and insulators, applied in the field of spark plugs, can solve the problems of low reliability of spark plugs and easy erosion of spark plugs, etc., and achieve the effect of improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

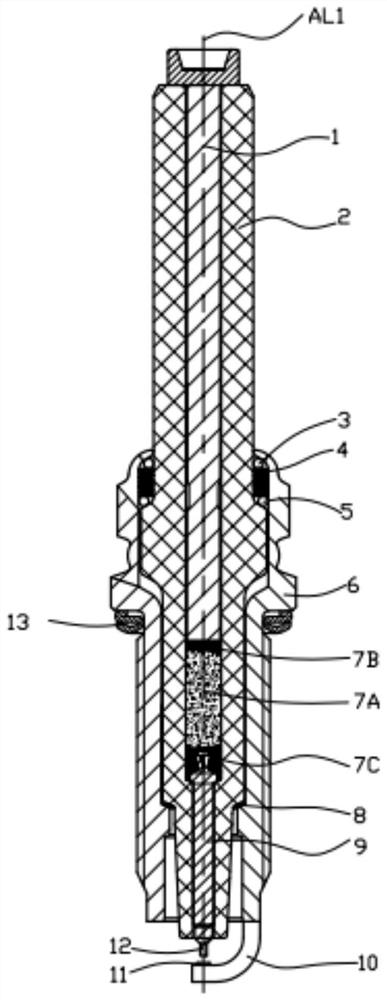

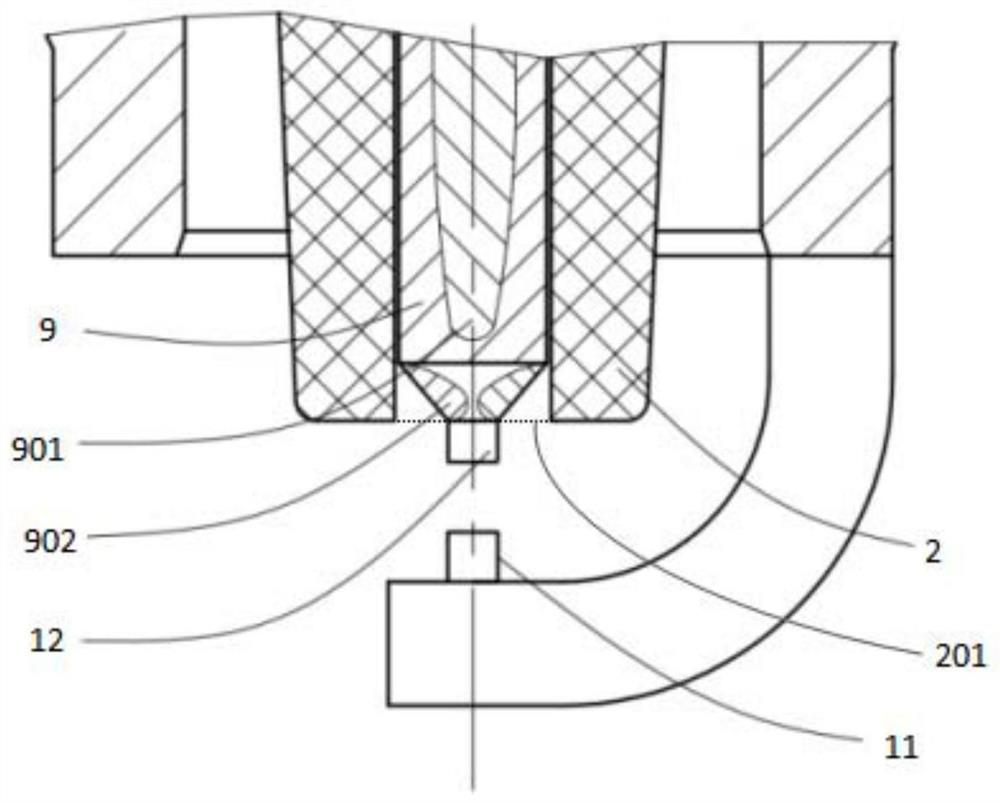

[0022] A spark plug such as figure 1 The shown includes a cylindrical insulator 2, the center of the insulator is provided with a stepped shaft hole along the axial direction, the center electrode 9 is arranged in the shaft hole, the outer side of the insulator 2 is wrapped with a metal shell 6, and the side electrode 10 is welded on the metal shell 6 and connected to the center. The electrodes 9 are oppositely arranged. The end of the central electrode 9 is welded with a noble metal end 12, and the side electrode 10 is provided with a noble metal end 11 opposite to the central electrode end, and there is a gap between the noble metal ends 11 and 12. A resistor body 7 is provided in the shaft hole opposite to the end of the center electrode 9. The resistor body includes a 7A resistor material, a 7B upper seal material, and a 7C lower seal material. The adjacent resistor body in the shaft hole is also provided with a wiring screw 1. The screw rod is connected with the ground n...

Embodiment 2

[0029] The difference between this embodiment and Embodiment 1 is that the overall structure of the fusion zone 902 coincides with the radial projection of the insulator 2 . The terminal connection lines on both sides of the end of the insulator are in the positive direction of the overall structure of the fusion zone. The terminal connection lines on both sides of the end of the insulator form a space with the insulator 2 , and the fusion zone 902 is entirely wrapped in the space. The distance between the end surface of the noble metal terminal 12 and the terminal connection line on both sides of the end of the insulator is +1mm to 0mm.

[0030] The spark plug of the present invention and four samples with different characteristics of the existing spark plug are selected to carry out durability assessment on the engine stand, and the technical effect of the present invention is verified as follows.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com