Combined transformer coil support system

A combined transformer and coil support technology, applied in the field of transformers, can solve the problem of no axial heat dissipation channel, etc., and achieve the effects of improving mechanical stability and reliability, simplifying heat dissipation structure and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Preferred embodiments of the present invention are described below with reference to the accompanying drawings. Those skilled in the art should understand that these embodiments are only used to explain the technical principle of the present invention, and are not intended to limit the protection scope of the present invention.

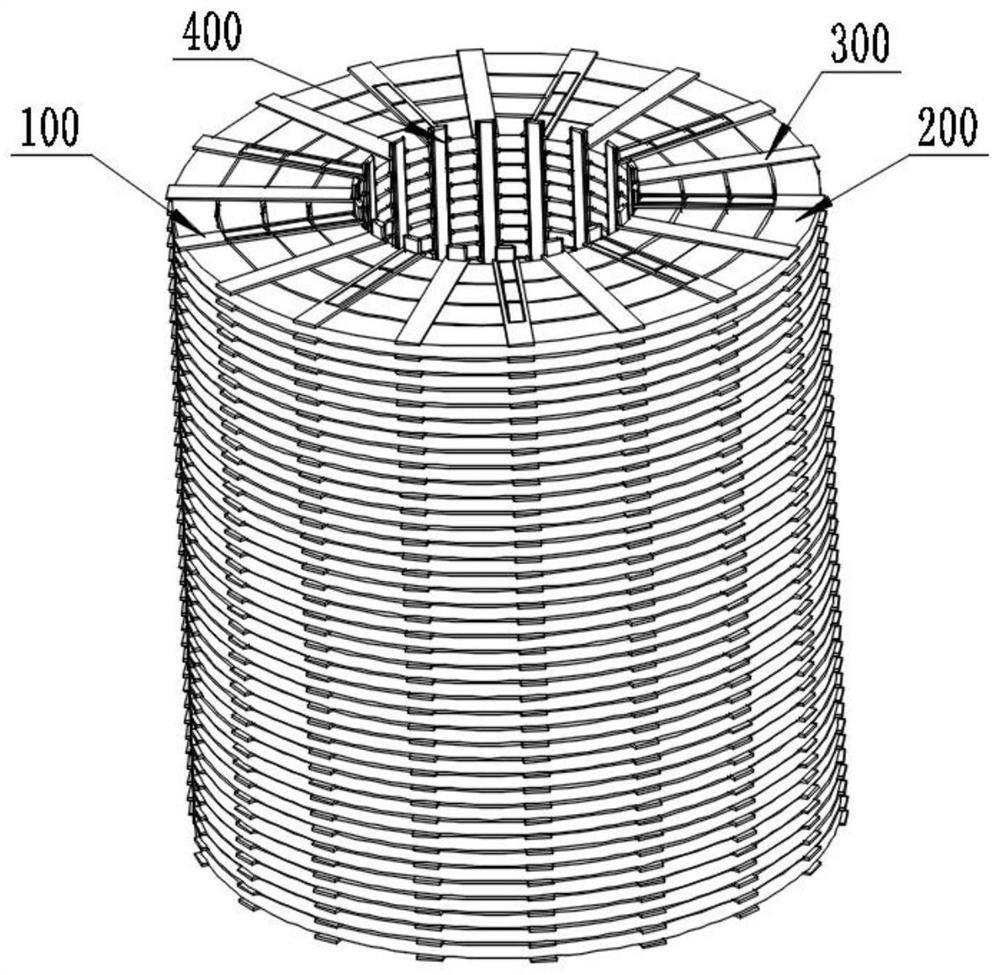

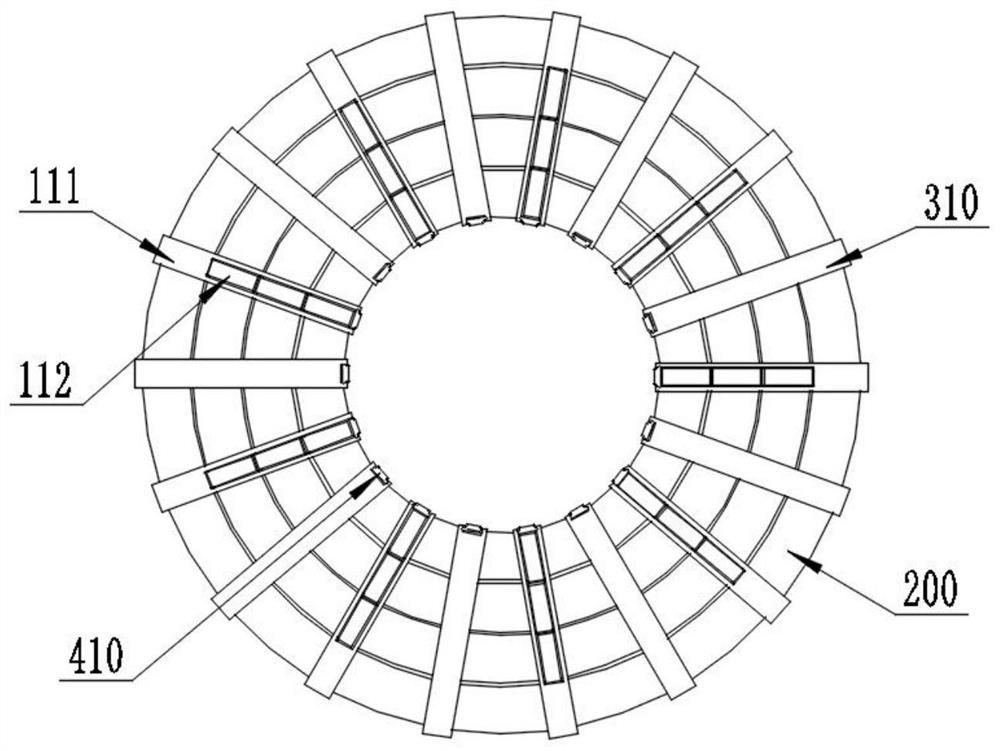

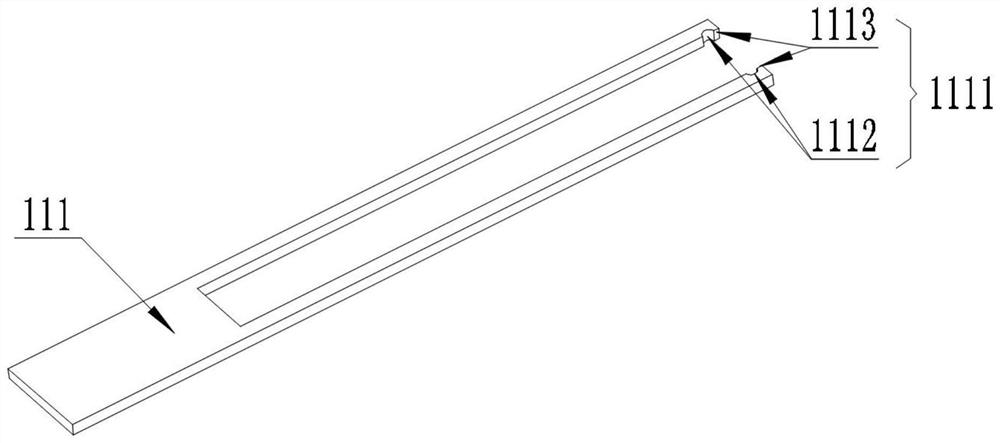

[0037] The invention provides a combined transformer coil support system, which includes a multi-layer support assembly for carrying coil cakes, and the multi-layer support assembly is connected as a whole through an axial connection assembly; each layer of support assembly includes M combined Spacer unit, M combined spacer units are arranged in a radial array on each layer of coil cake; the combined spacer units arranged on adjacent coil cakes are arranged alternately; the combined spacer unit includes a bracket assembly and two grooved gaskets, two Two grooved gaskets are respectively arranged on the upper and lower sides of each layer of coil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com