Textile industry waste heat recovery system with automatic cleaning and fire extinguishing functions

A waste heat recovery system and automatic cleaning technology, which is applied in the direction of cleaning heat transfer devices, lighting and heating equipment, washing, etc., can solve the problems of increased power consumption of fans, decreased heat exchange efficiency, and waste of heat energy, etc., to prevent blockage of cooling fins , Improve the efficiency of waste heat recovery and ensure the effect of cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

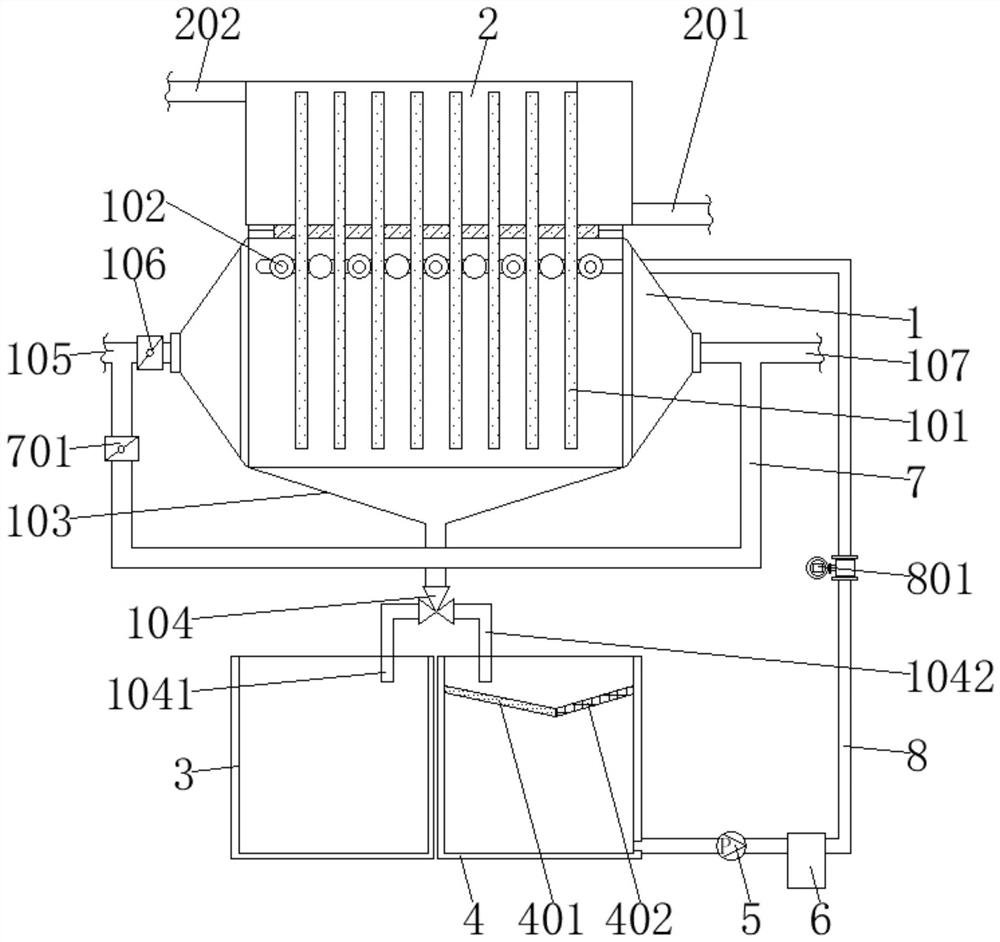

[0032] Such as figure 1 As shown, a waste heat recovery system for the textile industry with automatic cleaning and fire extinguishing functions, including a flue gas chamber 1, a waste heat recovery chamber 2, an oil storage tank 3, a cleaning liquid tank 4, a pump 5, a filter 6, and a flue gas chamber 1 is fixed with a plurality of heat pipes 101, and the top of the flue gas chamber 1 is horizontally arranged with a number of hollow shower heads 102. The bottom is fixed with a diversion bucket 103, and the bottom port of the diversion bucket 103 is connected with a sewage collection switching valve 104 through a conduit. The left and right sides of the sewage collection switching valve 104 are equipped with a first discharge short pipe 1041 and a second discharge short pipe 1041. The short pipe 1042, the air inlet pipe 105 is installed at the air inlet end of the left outer wall of the smoke chamber 1, and the fire damper 106 is installed at the end of the air inlet pipe 105...

Embodiment 2

[0047] Such as figure 2 As shown, a waste heat recovery system for the textile industry with automatic cleaning and fire extinguishing functions, including a flue gas chamber 1, a cooling water chamber 2, an oil storage tank 3, a cleaning liquid tank 4, a pump 5, a filter 6, and a flue gas chamber 1 is fixed with a plurality of heat pipes 101, and the top of the flue gas chamber 1 is horizontally arranged with a number of hollow shower heads 102. The bottom is fixed with a diversion bucket 103, and the bottom port of the diversion bucket 103 is connected with a sewage collection switching valve 104 through a conduit. The left and right sides of the sewage collection switching valve 104 are equipped with a first discharge short pipe 1041 and a second discharge short pipe 1041. The short pipe 1042, the air inlet pipe 105 is installed at the air inlet end of the left outer wall of the smoke chamber 1, and the fire damper 106 is installed at the end of the air inlet pipe 105 clos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com