Inerter energy-consuming and efficiency-increasing device

A kind of inertial and No. 1 technology, applied in the field of inertial energy consumption and efficiency enhancement devices, can solve the problems of cylinder jacking, difficult processing, complicated mechanism, etc., and achieve the effect of controlling dynamic response, simple processing, and clear mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

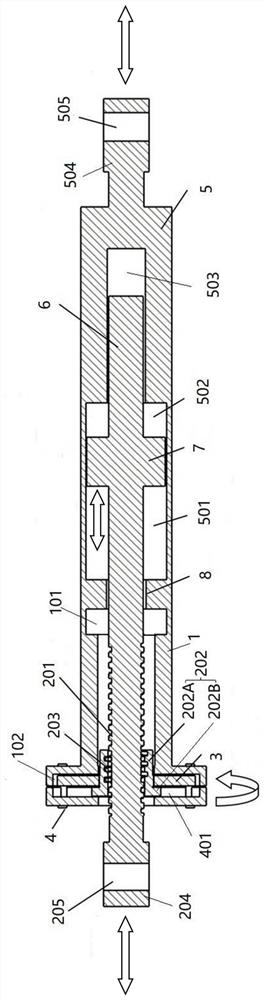

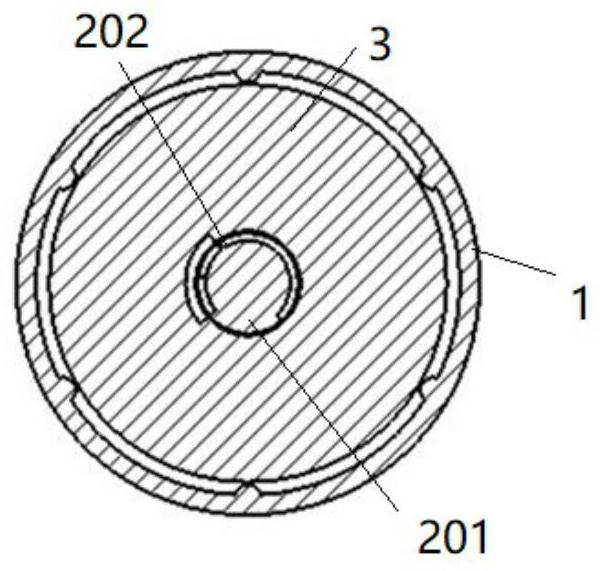

[0038] Such as figure 1 , 2 As shown in , 3, an inertia energy consumption synergistic device includes a ball screw inertial component and a viscous damping component, figure 2 The straight arrow in the direction of the ball screw inertial component in the figure points outward, indicating that the screw 201 moves axially outward, and the curved arrow indicates that the flywheel 3 is rotated by the movement of the screw 201. figure 2 The straight arrow in the direction of the viscous damping component points outward, indicating that the second outer cylinder 5 moves outward axially. At this time, the guide rod 6 moves axially in the opposite direction relative to the second outer cylinder 5, so that the piston 7 stirs Viscous fluid in the first chamber 501.

[0039] The ball screw inertial component includes No. 1 outer cylinder 1, a screw pair, a flywheel 3 and a flange 4. The No. 1 outer cylinder 1 is T-shaped, and the end with a larger outer diameter is used for setting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com