Intelligent automatic concrete pavement leveling device for building construction

A technology for concrete pavement and building construction. It is applied in the direction of buildings, roads, roads, etc. It can solve the problems of affecting the efficiency of road leveling, consuming manpower and time, and not being smart and flexible in use, so as to achieve the effect of firm structure and good protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

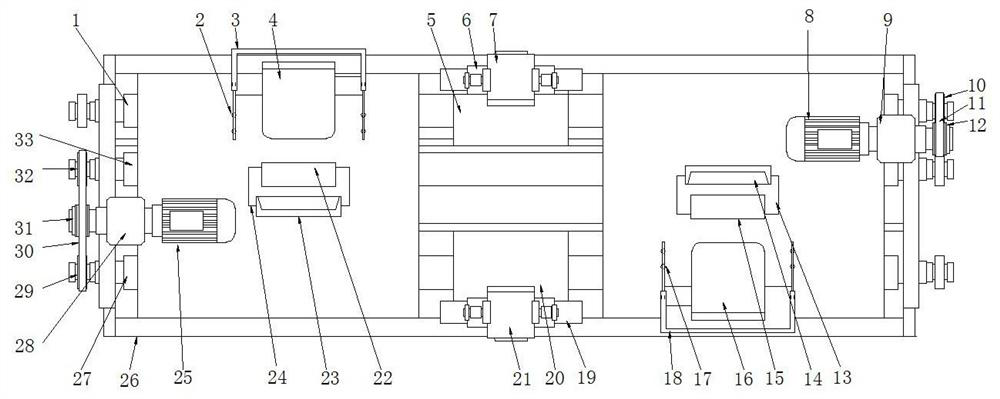

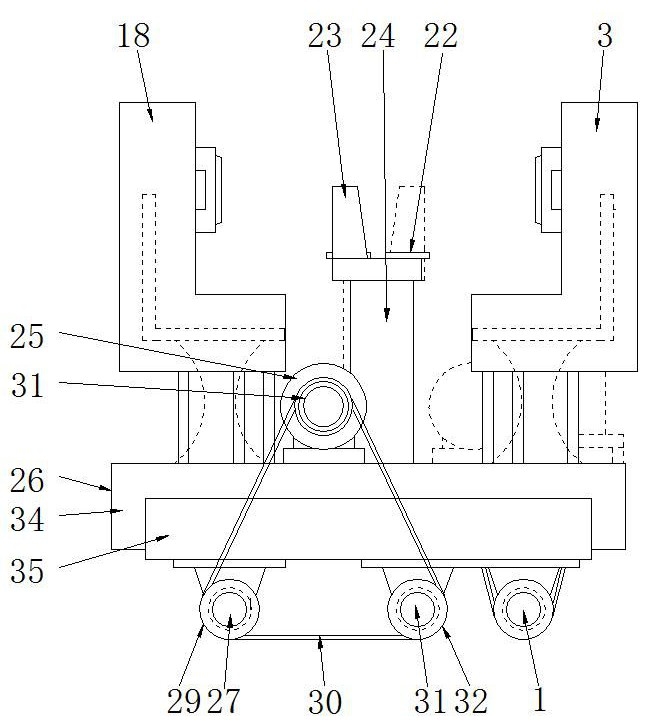

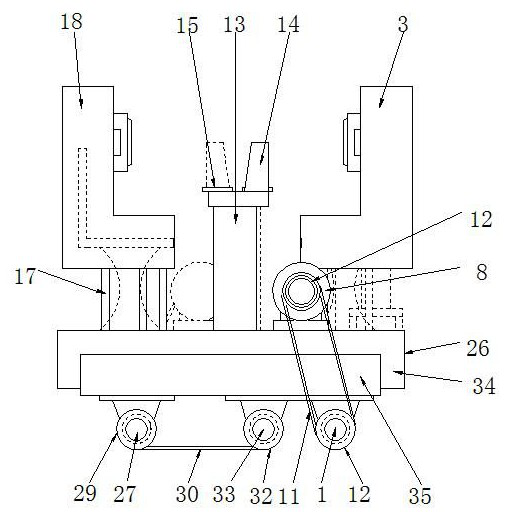

[0030] Specific implementation mode one, refer to Figure 1-7 , the present invention provides a technical solution: an intelligent automatic concrete road leveling device for building construction, including a first roller 1, a mounting frame 26, a second roller 27 and a third roller 33, the The upper part of the first rolling roller 1 is provided with an upper frame body 34, and the lower part of the first rolling roller 1 is provided with a lower frame body 35, and the bottom front side of the lower frame body 35 is equipped with the first rolling roller 1, and The middle side of the bottom of the lower frame body 35 is equipped with a third rolling roller 33, and the bottom rear side of the lower frame body 35 is equipped with a second rolling roller 27, and the front end of the middle part of the upper end surface of the upper frame body 34 is provided with a front fixing plate 5, and the first base 6 is arranged on the front fixing plate 5, and the front infrared line su...

specific Embodiment approach 2

[0032] Specific embodiment two, the upper and lower parts of the mounting frame 26 in the present invention are respectively an upper frame body 34 and a lower frame body 35, and a first The rear protective cover 3 is used to protect the safety of the operator sitting on the first seat 4. At the same time, a plurality of sets of first support rods 2 are arranged at the bottom of the first rear protective cover 3, and the supporting structure is set firm and firm, so that the operation It is safer and more reliable for personnel to use;

specific Embodiment approach 3

[0033] Specific embodiment three, the second seat 16 is arranged on the right part of the upper end face of the upper frame body 34, and the second rear protective cover 18 is arranged at the rear of the second seat 16, which is used to protect people sitting on the second seat 16. The safety of the operator, at the same time, the bottom of the second rear protective cover 18 is provided with multiple sets of second support rods 17, which makes the setting more firm and firm, so that it can be better protected and safer to use;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com