Novel container longitudinal bulkhead protection device

A protective device and container technology, which is applied in packaging, large containers, transportation and packaging, etc., can solve the problems of shaking, bulkhead damage, and easy direct impact on the bulkhead of the container, etc., to achieve reduction and good protection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

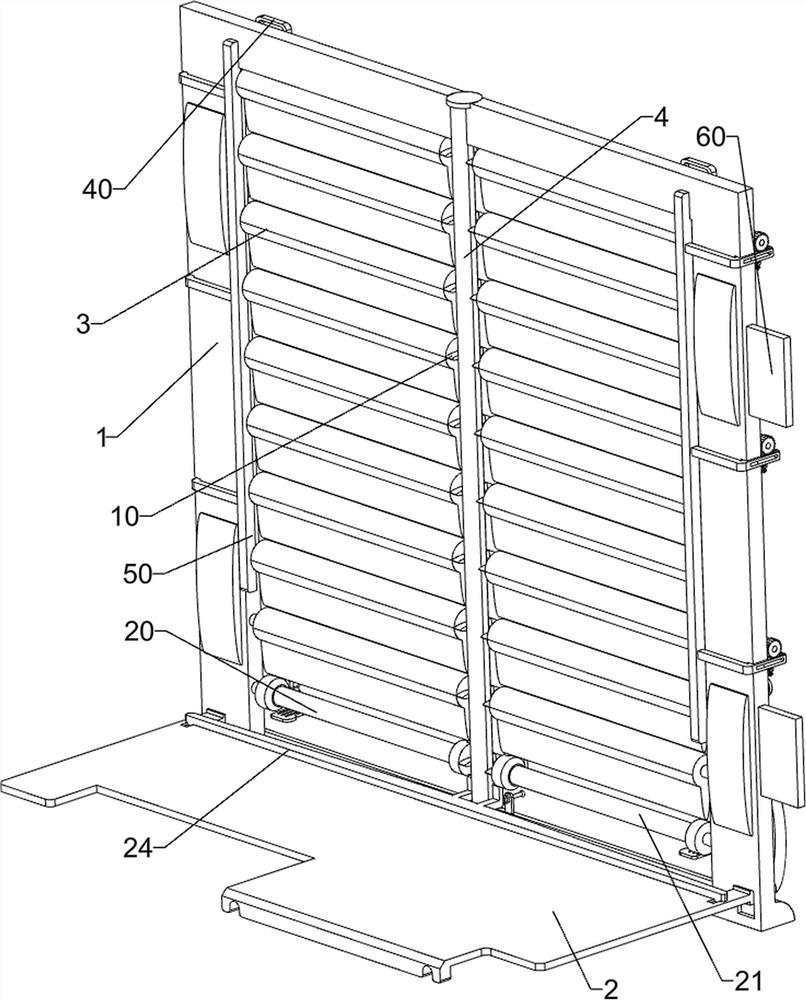

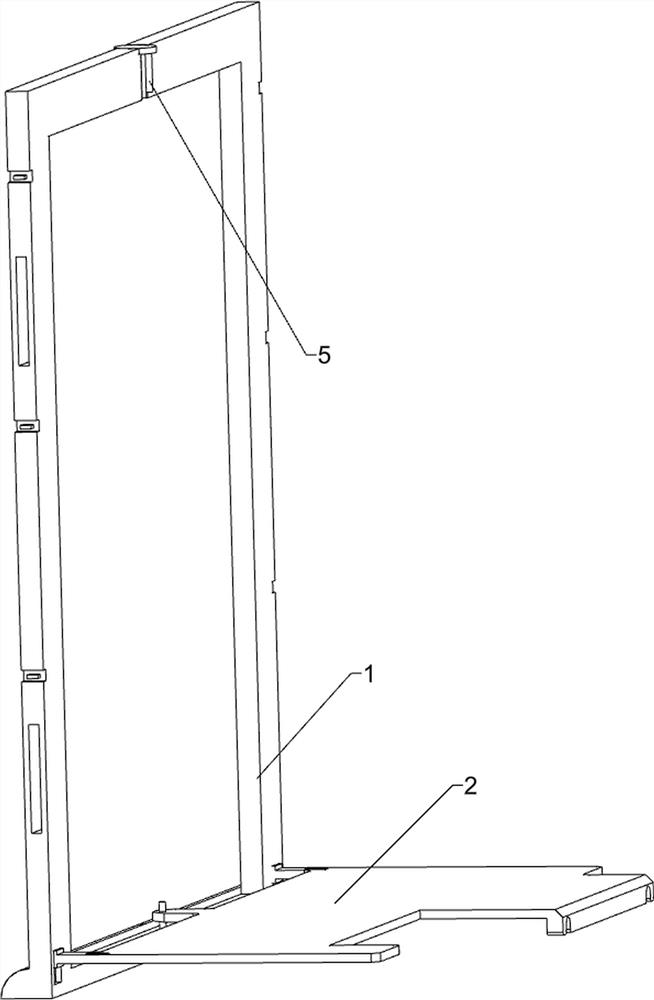

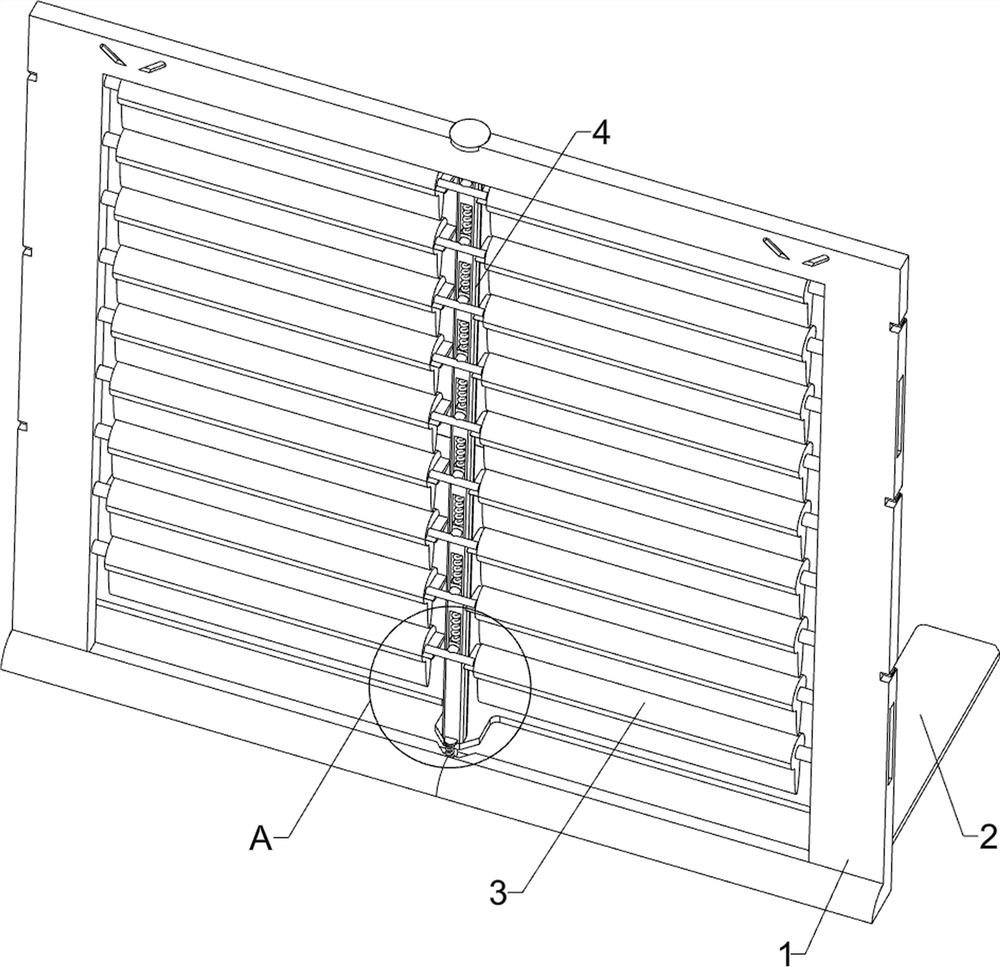

[0041] A new type of container longitudinal bulkhead protection device, such as Figure 1-5As shown, it includes a frame body 1, a supporting base plate 2, a shifting plate 3, a sliding rod 4, a guide post 5, an initial spring 6 and a buffer mechanism 10, and the lower left side of the frame body 1 is slidably connected with a supporting base plate 2 through a chute. Bottom plate 2 is used to support objects, and the front and rear walls of frame body 1 are longitudinally evenly spaced and rotationally connected with a plurality of dials 3. The dials 3 on both sides are symmetrically arranged front and rear, and dials 3 are used to align the longitudinal bulkhead of the container. For protection, the inner top and inner bottom of the frame body 1 are symmetrically connected with guide posts 5, and the sliding rod 4 is slidably connected between the upper and lower guide posts 5, the top of the supporting base plate 2 is connected with the bottom of the sliding rod 4, and the lo...

Embodiment 2

[0046] On the basis of Example 1, such as figure 1 , Figure 5 , Image 6 and Figure 7 As shown, a stabilizing mechanism 20 is also included. The bottom of the frame body 1 is connected with a stabilizing mechanism 20. The stabilizing mechanism 20 is used to clamp the articles in the lower part of the container to protect the articles. The stabilizing mechanism 20 includes a rotating shaft 21 and a second pressing plate 22. , fixed pressure bar 23, clamping plate 24, arc push rod 25, connecting rod 26 and back-moving spring 27, all the lower parts of the front and back side walls in the frame body 1 are rotatably connected with rotating shafts 21, and the rotating shafts 21 on both sides are symmetrically arranged front and rear , the inner sides of the rotating shafts 21 on the front and rear sides are connected with the second pressure plate 22, the lower part of the right side of the slider 4 is connected with the fixed pressure rod 23, the fixed pressure rod 23 can push...

Embodiment 3

[0051] On the basis of Example 2, such as figure 1 , Figure 9 and Figure 10 As shown, a fixing mechanism 40 is also included. The right side of the frame body 1 is connected with a fixing mechanism 40. The fixing mechanism 40 is used to fix the frame body 1 in the container. The fixing mechanism 40 includes a mounting sleeve 41, a wedge-shaped pull rod 42, a clip Wheel 43, pull plate 44, tension spring 45 and fork 46, four mounting sleeves 41 are symmetrically connected to the front and rear sides of the right side of the frame body 1, and there are sliding connections between the two mounting sleeves 41 corresponding up and down. Wedge-shaped pull rods 42, two wedge-shaped pull rods 42 are symmetrically arranged front and back, and the front and rear sides of the upper right side of the frame body 1 are connected with four card wheels 43 in a symmetrical sliding manner through inclined grooves. The wedge-shaped pull rods 42 can push the card wheels 43 to move. The bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com