A method for preparing high-concentration sulfur dioxide gas from industrial by-product gypsum slag

A technology for industrial by-products of gypsum and sulfur dioxide, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of unfavorable low-cost production of sulfuric acid and low concentration of sulfur dioxide, and achieve the effect of improving decomposition efficiency and promoting decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with specific examples.

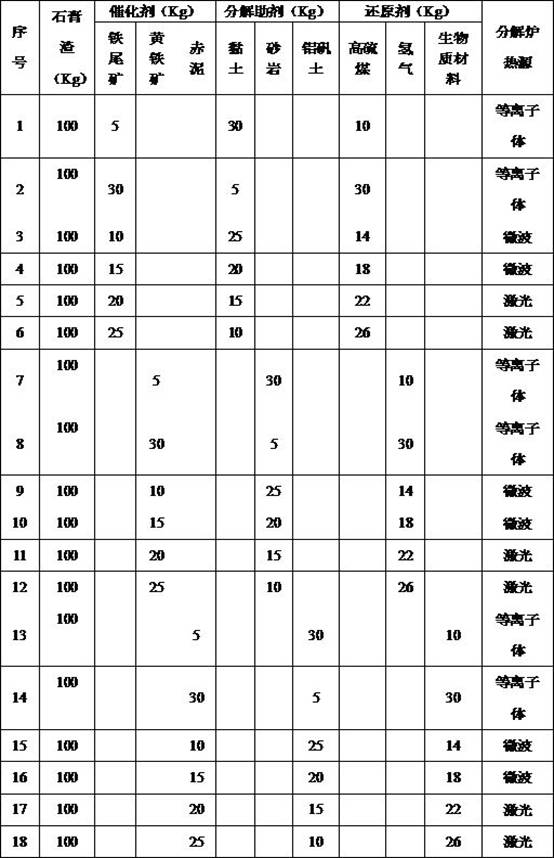

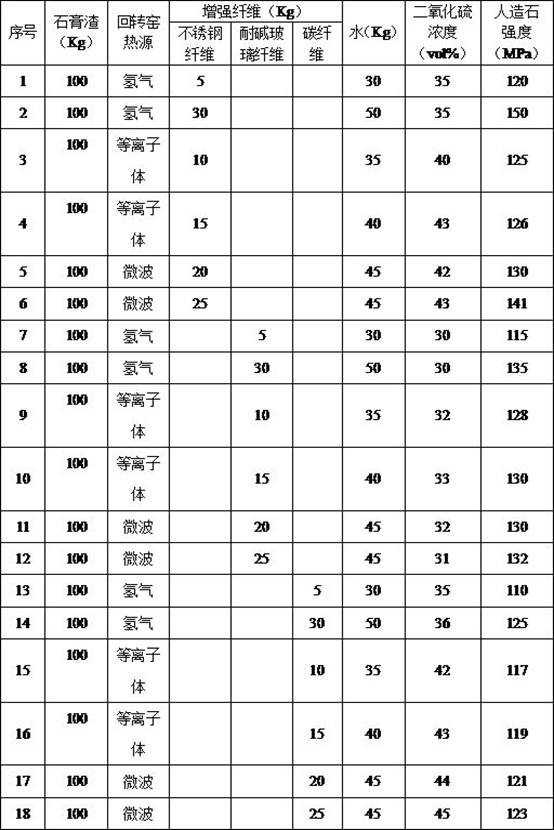

[0031] A method for preparing high-concentration sulfur dioxide gas from industrial by-product gypsum slag, which is characterized in that it includes the following steps in sequence: the gypsum slag is uniformly mixed with a catalyst and a decomposition aid to obtain raw meal, and the raw meal enters the preheater of the kiln tail system After medium preheating, it enters the calciner of the kiln tail system, and at the same time, a reducing agent is added to the calciner to decompose and react the gypsum in the raw material to obtain an intermediate phase, and then the intermediate phase enters the rotary kiln, and the intermediate phase reacts in the rotary kiln Obtaining clinker; cooling and grinding the clinker, adding reinforcing fibers and water, stirring evenly, forming, carbonizing and curing, to obtain artificial stone. See Table 1 for the formula of cataly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com