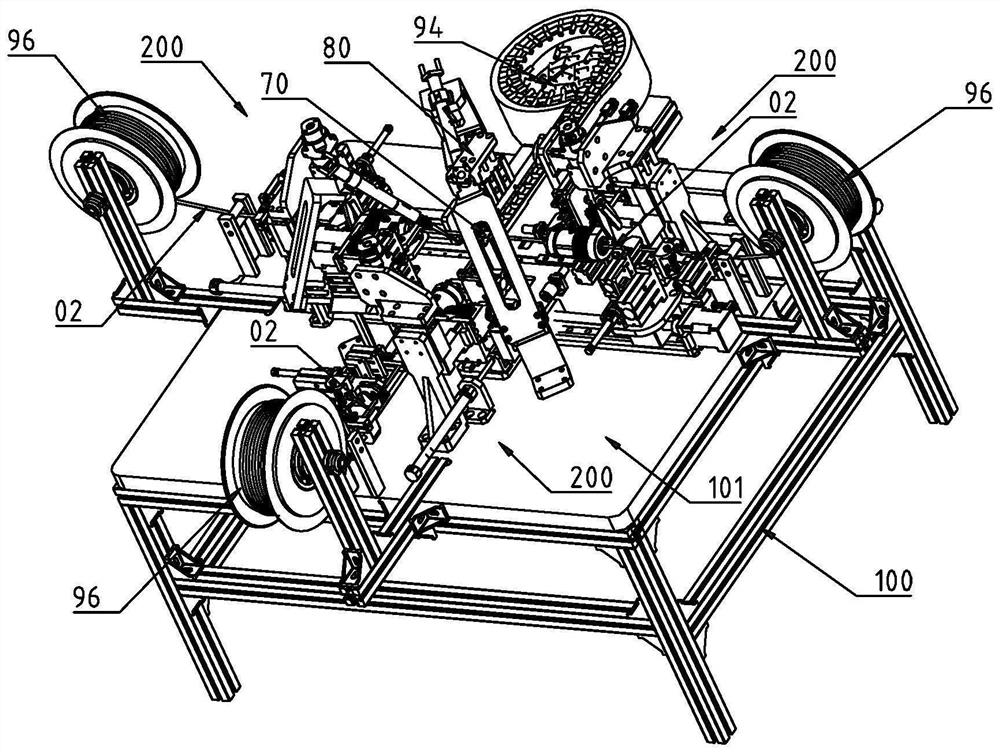

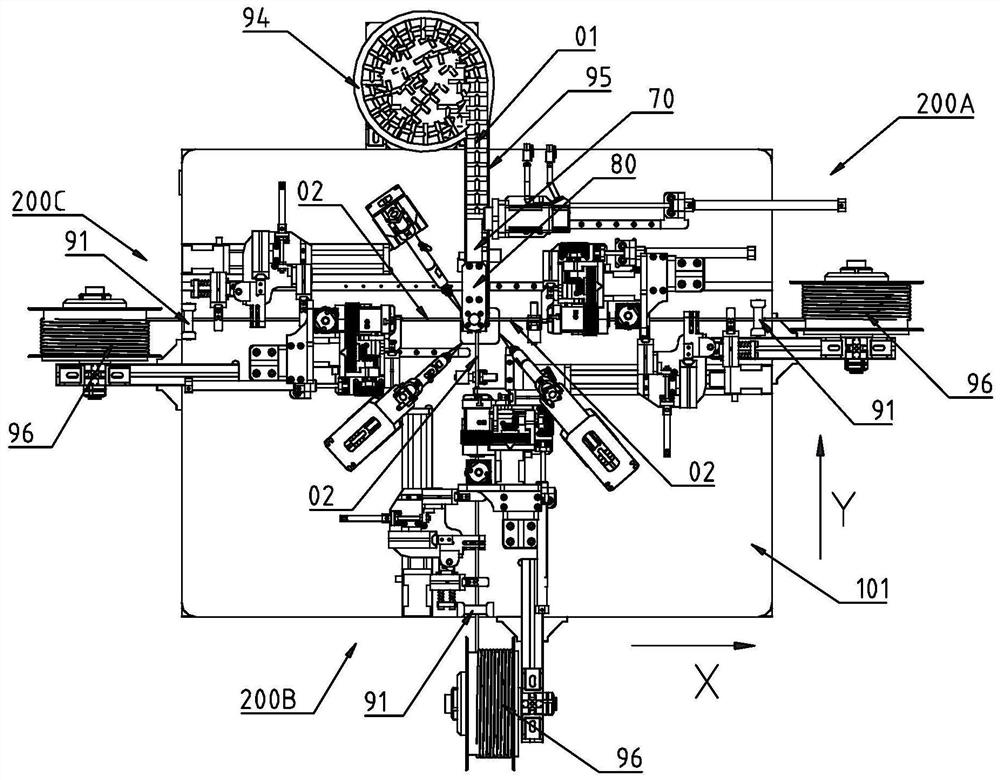

Method for assembling infusion hose and T-shaped three-way connector

A technology of infusion hose and tee joint is applied in the field of assembly of infusion hose and T-type tee joint, which can solve the problems of poor assembly quality, low assembly efficiency, unsuitable for large-scale production and the like, and achieves good assembly quality, The effect of high assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

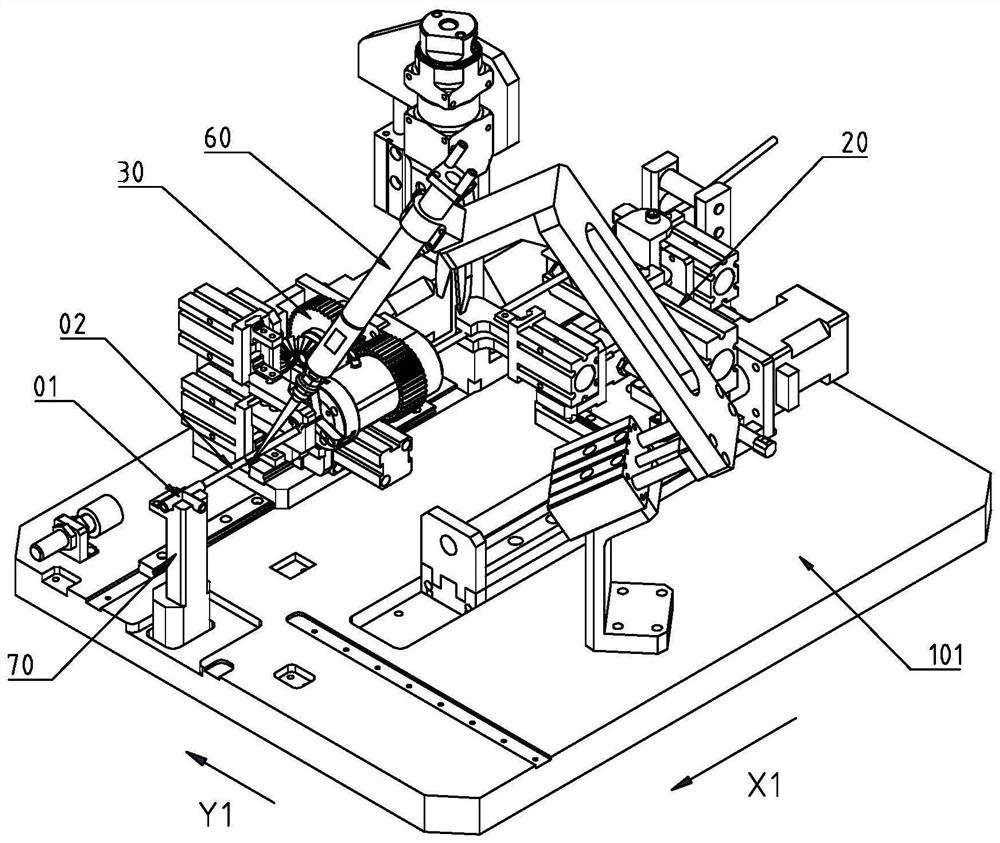

Embodiment 2

[0103] The length of the rubbing clamp 35A along the X1 axis in the hose secondary insertion mechanism in Embodiment 2 is much smaller than the length of the general three-jaw cylinder 351 and the passive cylindrical gear 353 along the X1 axis in the hose secondary insertion mechanism in Embodiment 1. Length, the infusion hose after the pneumatic clamp 28 is cut in front of the X1 axis is shorter, and one support can be reduced, so the hose delivery device 20 of embodiment 2 can be equipped with one pneumatic clamp 27 less than that of embodiment 1, and can also be omitted at the same time Drop line module 22.

[0104]In Embodiment 2, the hose secondary insertion mechanism 35 includes a three-rod cylinder 354, a gear shaft 355, a hose clamp 35A, a rack 356, a rack bracket 357 and an eighth linear guide pair. The eighth linear guide rail pair shares the guide rail 3322 with the third linear guide rail pair, and the guide rail 3322 is fixed on the machine base 32 along the Y-axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com