Needle plate ball screening machine

A ball screening machine and needle plate technology, applied in the field of ball screening equipment, can solve the problems of extensive screening methods and inability to screen steel balls, and achieve the effects of improving grinding effect and screening accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

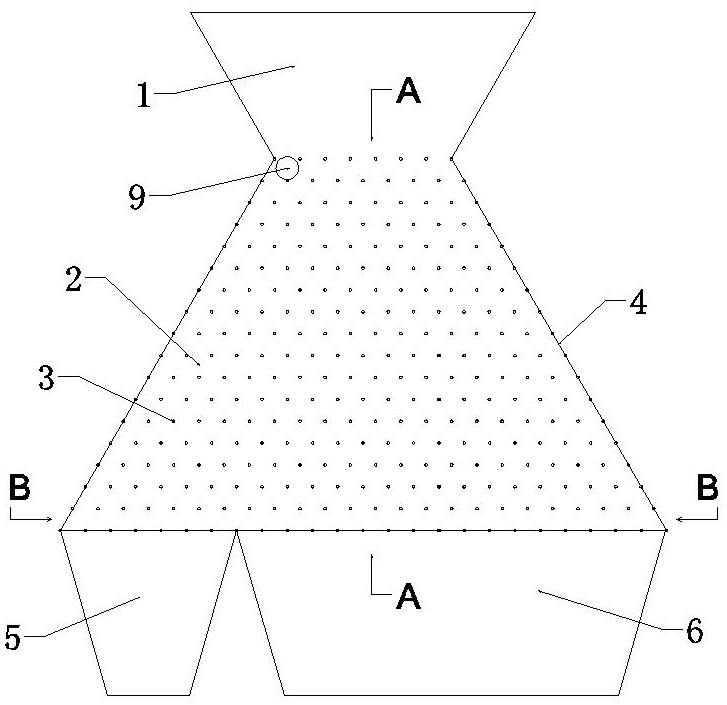

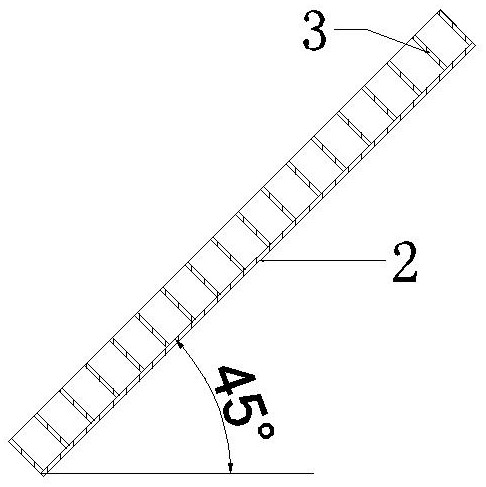

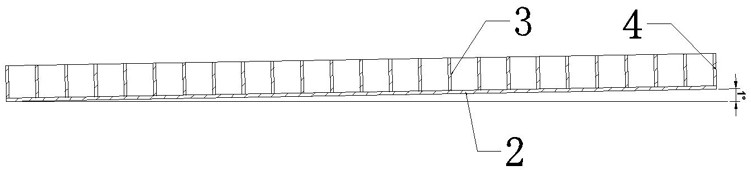

Embodiment 1

[0022] see Figure 2 to Figure 4 , when it is necessary to sieve to obtain steel balls with a diameter of 8.70mm, the distance between the fixed points at the lower ends of the striker 3 is 9mm, the inclination angle of the bottom plate 2 in the vertical direction is 45°, and the left and right inclination angle of the bottom plate 2 is 1° (the left side is lower, the right side is lower). Side height), at this time, the maximum diameter of the sphere that can pass between the striker 3 rods is 8.70mm. Other structures of the needle plate ball sieving machine remain unchanged. The balls to be screened 9 enter the needle plate ball screening machine from the feeding chute 1, and the steel balls with a diameter of 8.70mm are affected by the left and right inclinations of the bottom plate 2. The trajectory of the impact movement is leftward, and finally falls into the left finished product groove 5 Inside, the steel ball with a diameter of less than 8.70mm enters the second floo...

Embodiment 2

[0024] see figure figure 2 with Figure 5 , when it is necessary to sieve to obtain steel balls with a diameter of 8.38 mm, the distance between the fixed points at the lower end of the firing pin 3 is 9 mm, the bottom plate 2 is tilted 45° in the vertical direction, and the bottom plate 2 is tilted left and right by 2° (lower on the left side and higher on the right side). The maximum diameter of the sphere that can pass between the striker 3 rods is 8.38mm. The other structures of the needle-plate ball sieving machine remain unchanged, and the sieving process is the same as that of Example 1. Finally, steel balls with a diameter of 8.38 mm are obtained to achieve precise sieving.

Embodiment 3

[0026] see figure 2 with Figure 6 , when it is necessary to sieve to obtain steel balls with a diameter of 8.08mm, the distance between the fixed points at the lower end of the striker 3 is 9mm, the bottom plate 2 is tilted 45° in the vertical direction, and the bottom plate 2 is tilted left and right by 3° (lower on the left side and higher on the right side). The maximum diameter of the sphere that can pass between the striker 3 sticks is 8.08mm. The other structures of the needle-plate ball sieving machine remain unchanged, and the sieving process is the same as that of Example 1. Finally, steel balls with a diameter of 8.08 mm are obtained to achieve precise sieving.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com