Drum-type chemical raw material screening device with speed regulation function

A screening device and drum-type technology, which is applied in the fields of filtration, chemical instruments and methods, solid separation, etc., can solve problems such as difficulty in realizing stepless speed regulation, affecting separation of small particle raw materials, rough raw materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

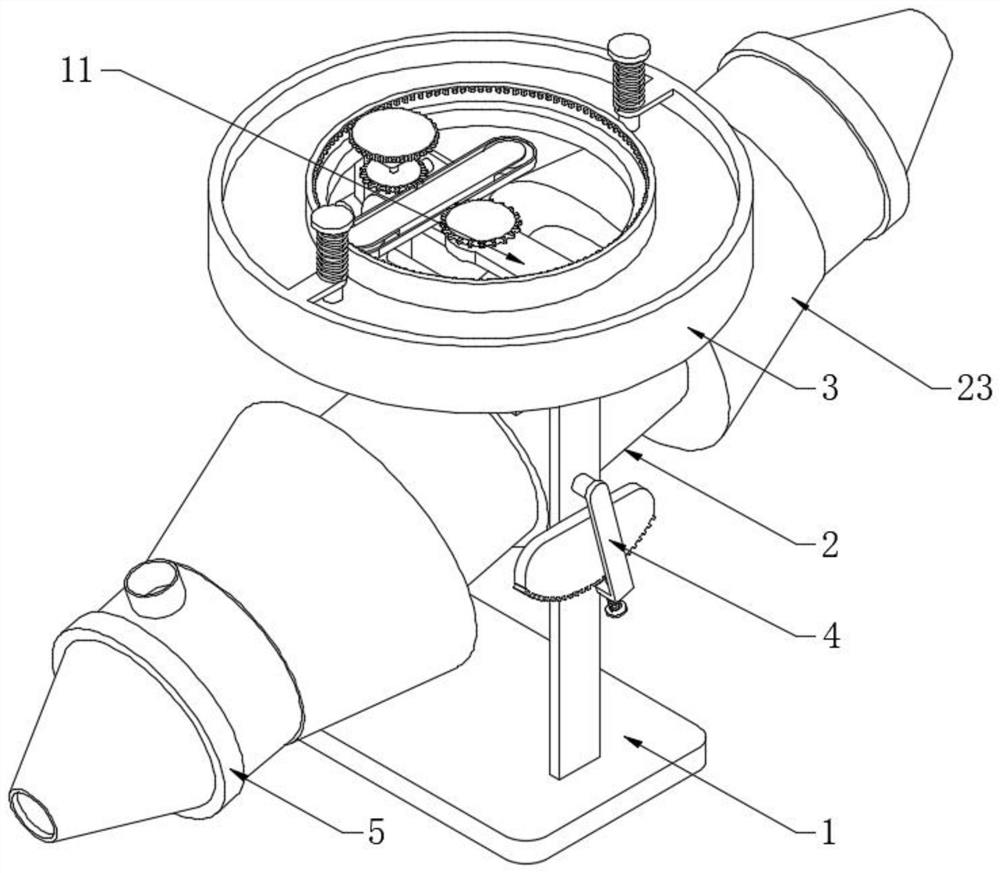

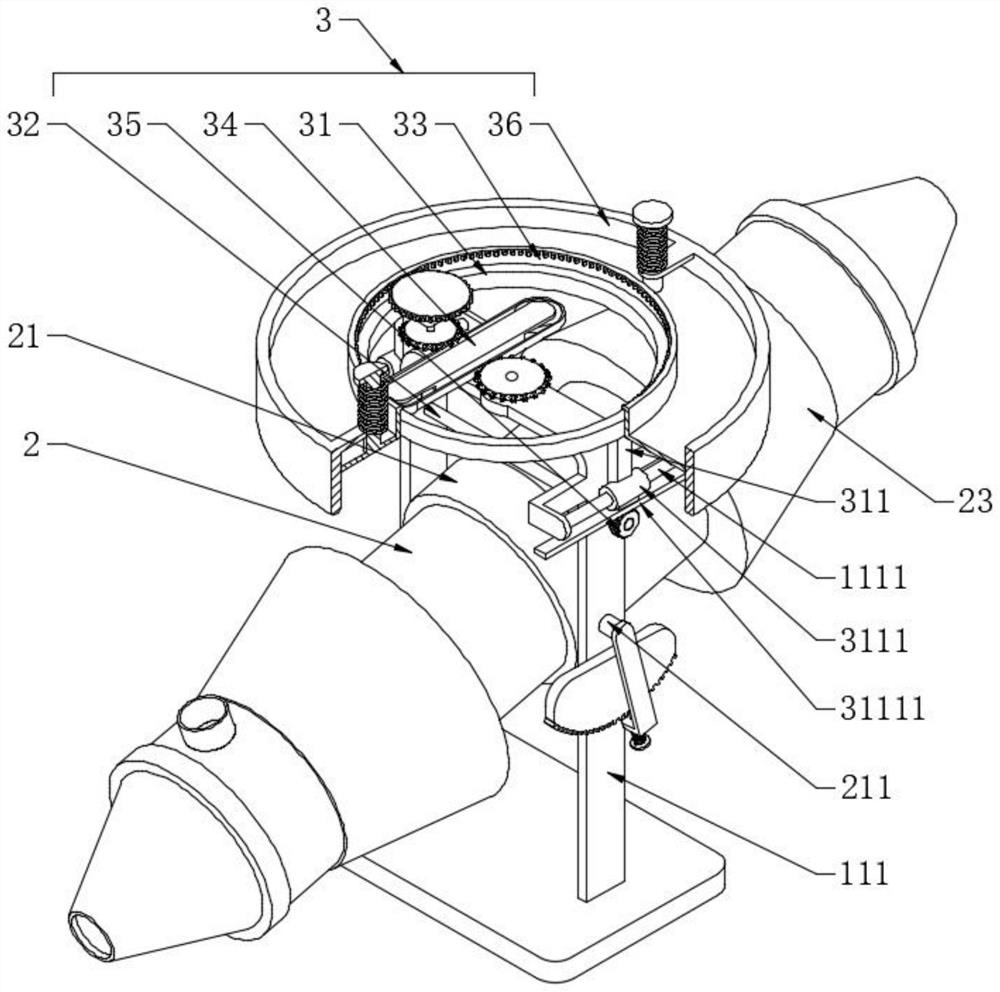

[0031] see Figure 1-3, a drum-type chemical raw material screening device with a speed regulating function, comprising a support frame 1, a cylinder 2 and a speed regulating combination 3, the upper end surface of the support frame 1 is fixedly provided with a portal frame 11, and the cylinder 2 is arranged on the portal The frame 11 is provided with a swivel 21 inside and outside, and the outer wall of the swivel 21 is fixedly provided with a support shaft 211 connected to the two vertical plates 111 on the portal frame 11. The cylinder 2 is distributed obliquely and has an upper height One end of the bottom is provided with a filter plate 22, and the speed regulating combination 3 is arranged on the top of the portal frame 11. The speed regulating combination 3 includes a supporting ring plate 31, an adjusting shaft 32, a driving sleeve 33, a power combination 34, a driving gear 35 and a transmission The sleeve 36, the support ring plate 31 and the portal frame 11 are slida...

Embodiment 2

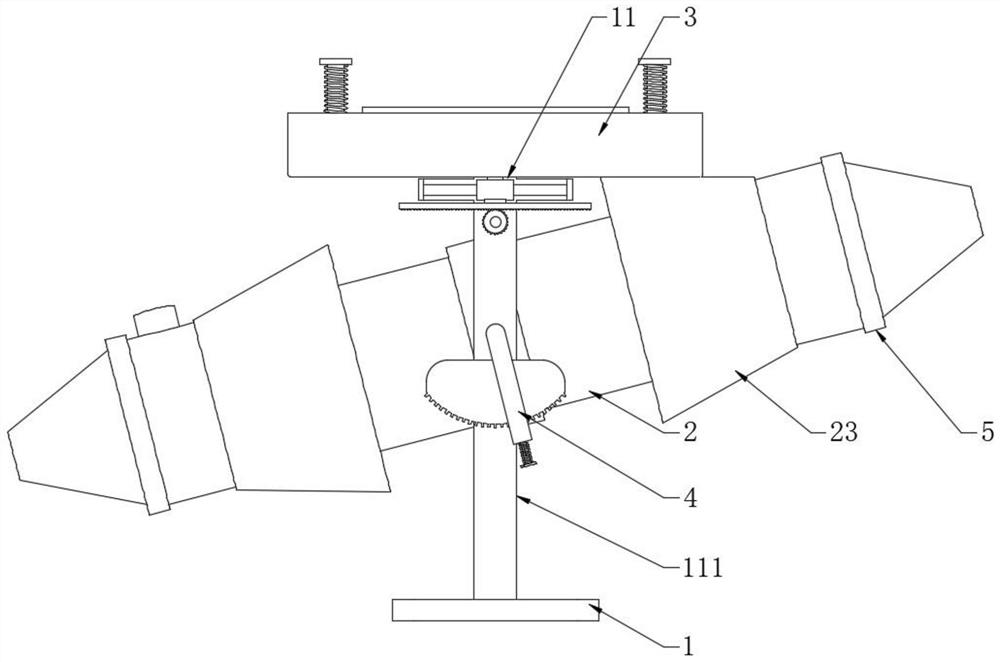

[0033] see image 3 with Figure 4 , and the difference from Embodiment 1 is that the drive sleeve 36 and the drive sleeve 33 are axial elastic sliding fit, that is to say, the drive sleeve 36 slides up and down relative to the drive sleeve 33. An annular disk, a column is fixedly arranged on the upper end surface of the annular disk, and then a supporting plate with a matching hole is arranged on the top of the transmission sleeve 36, the column runs through the matching hole, and a spring on the supporting plate is set on the column to realize elasticity. Sliding connection, the support shaft 211 and the vertical plate 111 are rotationally connected, thus the cylinder 2 can be controlled to swing with the support shaft 211 as the rotation center to change the inclination angle, and one end of the support shaft 211 passes through the vertical plate 111 and is fixedly connected to the limit rod 4. One side of the vertical plate 111 is fixedly provided with a locking plate 111...

Embodiment 3

[0035] see Figure 4 The difference from Example 2 is that the two ends of the cylinder 2 are provided with a cover 5, and one side of the cover 5 is fixedly provided with a conical discharge pipe 51, and the outer wall of the cylinder 2 is located between the conical sleeve 23 and the seal. A feed pipe 25 is arranged between the covers 5, and the feed pipe 25 adopts a structure with a plug. The cover 5 and the cylinder 2 are screwed and connected, and the second filter plate 24 and the first filter plate 22 are both split structures. The second filter plate 24 and the first filter plate 22 can be easily disassembled by removing the cover 5, and can also be replaced with different specifications, which is convenient to replace.

[0036] Working principle: when in use, the drive shaft 344 is controlled to rotate, the drive sprocket 341 rotates to drive the chain 3433 to rotate, the chain 3433 drives the drive sprocket 3422 to rotate, and then the drive gear 3421 rotates and dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com