High-molecular synthetic waterproof coiled material manufacturing method

A technology for a waterproof coiled material and a manufacturing method, which is applied in the directions of winding strips, pretreatment surfaces, and devices for coating liquids on surfaces, etc., can solve the problems of inability to process, difficult to adjust, low work efficiency, etc. Efficiency, avoidance of waste, the effect of saving necessary time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

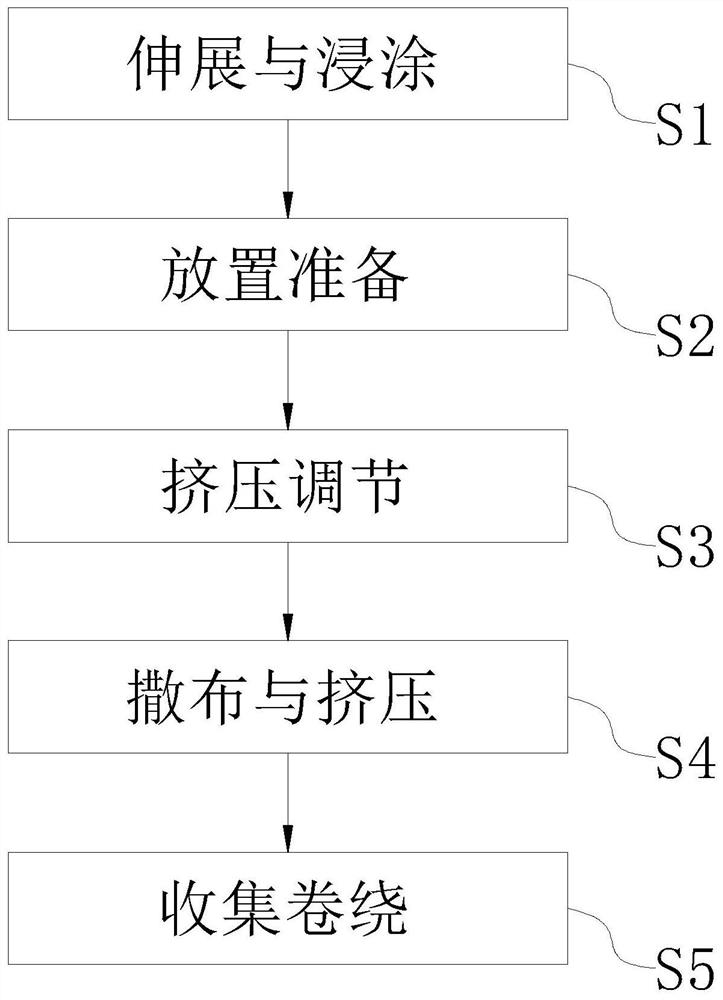

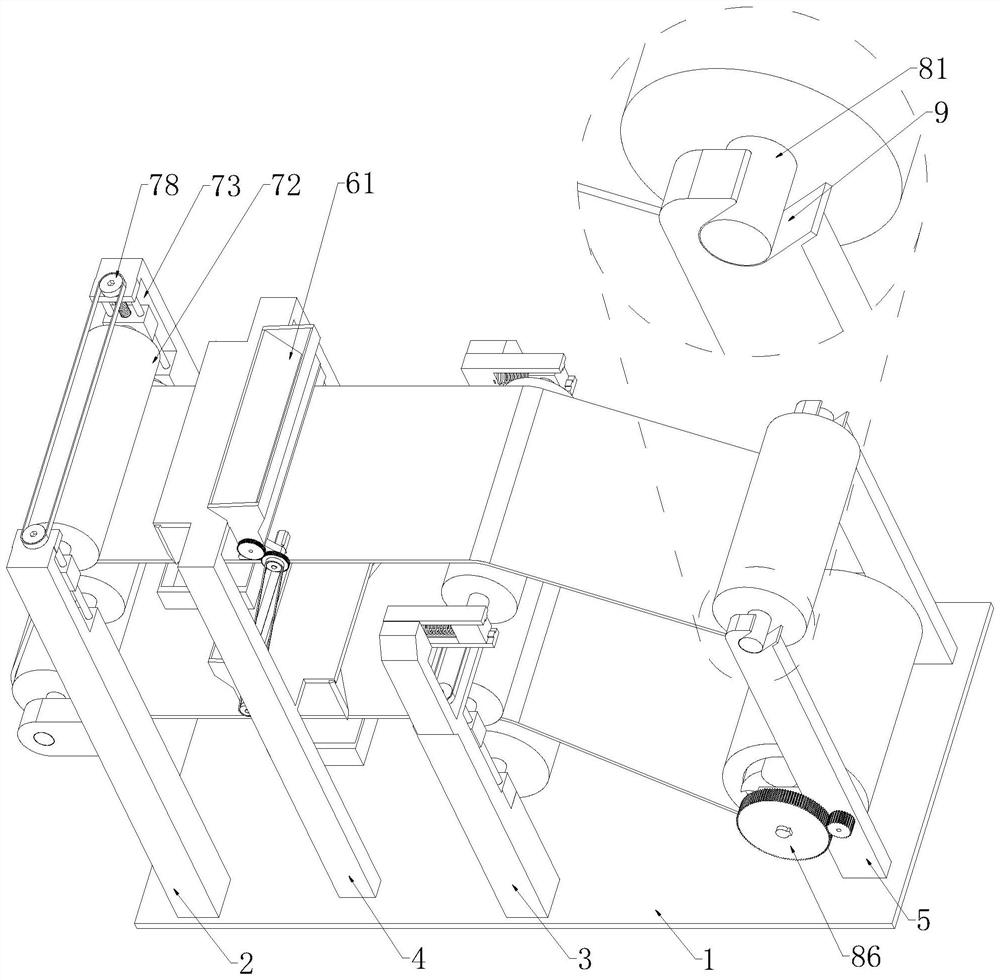

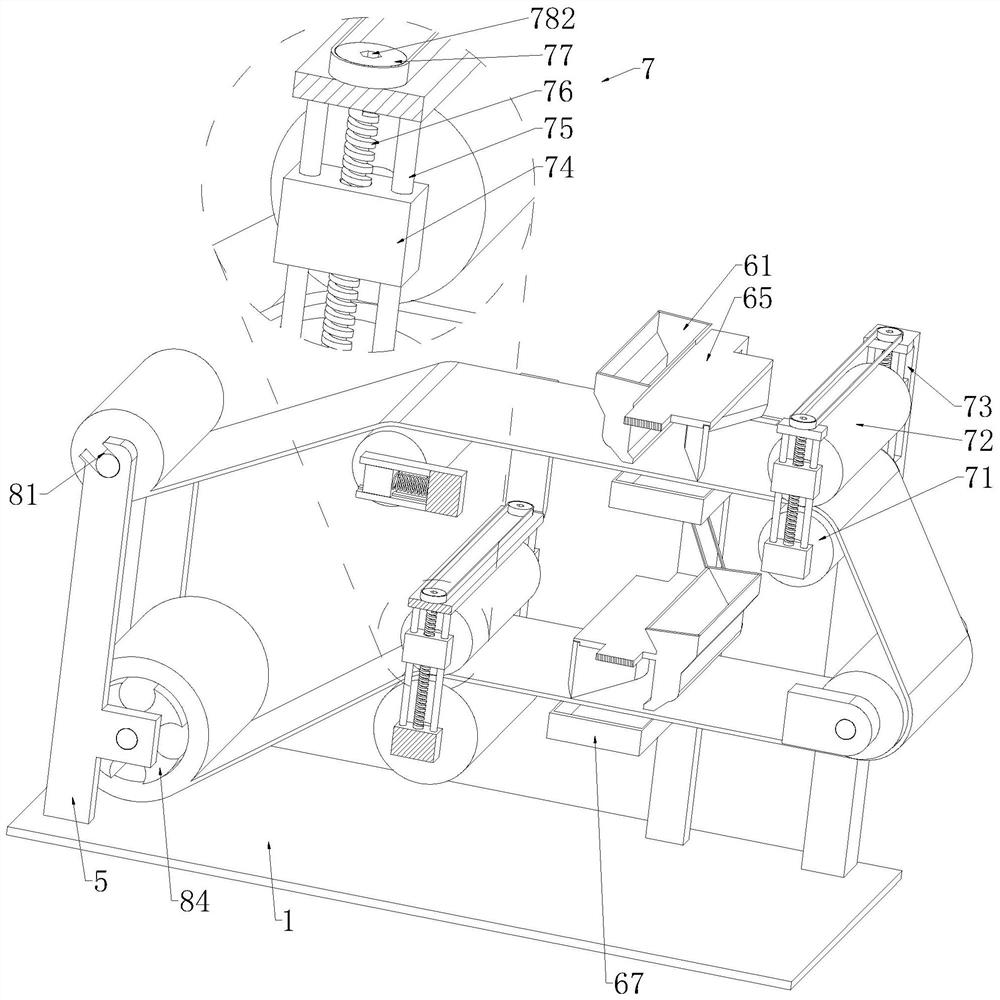

[0035] The following is attached Figure 1-8 The present invention is described in further detail.

[0036] It is a kind of polymer synthetic waterproof membrane production method of the present invention, and it has used a kind of waterproof membrane production equipment, and this equipment comprises bottom plate 1, front support frame 2, rear support frame 3, installation frame 4, placement frame 5, The spreading device 6, the extruding device 7 and the winding device 8, the bottom plate 1 is arranged on the ground, and several placement frames 5, several rear support frames 3, several installation frames 4 and several front support frames 2 are sequentially and symmetrically arranged on the bottom plate 1, In order to facilitate the installation of the spreading device 6, the extruding device 7 and the winding device 8, in this embodiment, the placement frame 5 is provided with an opening slot 9 that slides and fits with the receiving roller 84, and the opening slot 9 is se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com