Efficient assembly line for producing noodles

A high-efficiency, assembly-line technology, applied in applications, dough mixers, structural components of mixing/kneading machines, etc., can solve the problems of poor quality and low efficiency of flour aging, achieve good continuity, improve aging quality, and improve Effects of Efficiency and Uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

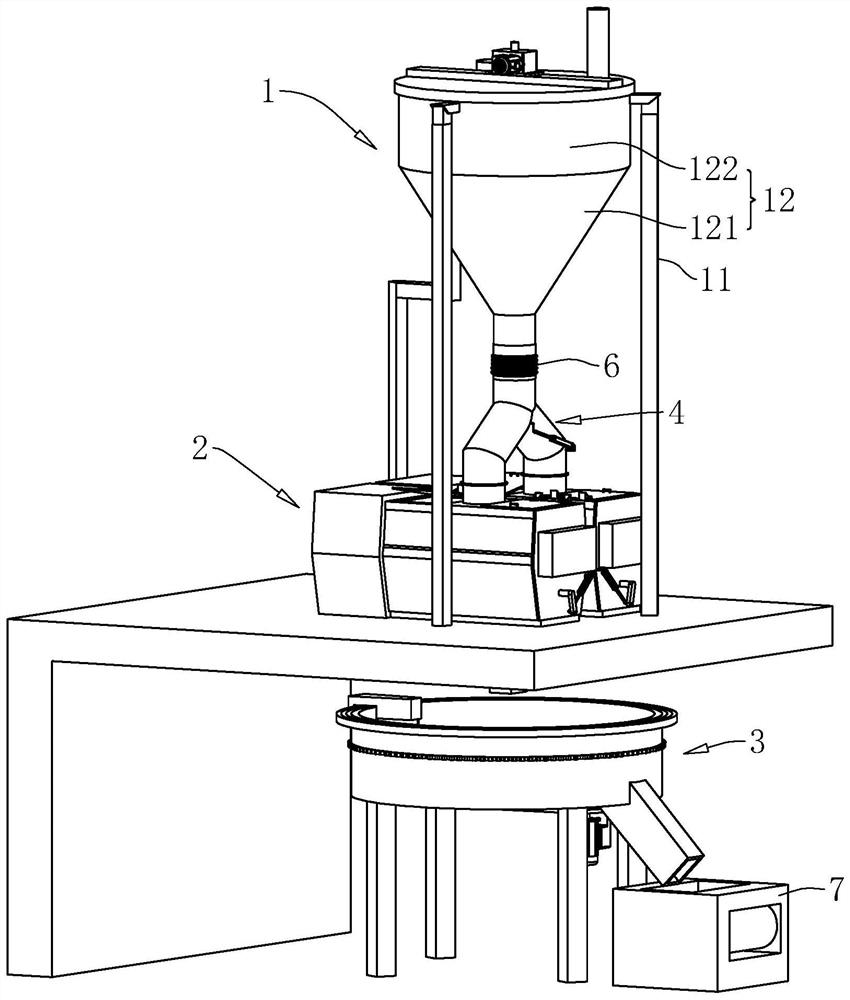

[0040] Attached to the following Figure 1-8This application will be described in further detail.

[0041] The embodiment of the present application discloses an efficient production line for producing noodles. refer to figure 1 , including a quantitative supply device 1, a dough mixing device 2 and a curing device 3, the quantitative feeding device 1 is used to add a certain amount of flour to the dough mixing device 2, and the flour is stirred in the dough mixing device 2 and water is added to make the flour form into granules The dough is then discharged into the curing device 3 , the dough is cooked by the curing device 3 , and the cured dough flows into the rolling device 7 .

[0042] refer to figure 2 , the quantitative supply device 1 includes a frame body 11, a storage tank 12 and a weigher 13, the lower part of the frame body 11 is fixed on the platform, the upper end of the frame body 11 is fixed with a weigher 13, and a storage tank 12 is fixed on the weigher 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com