A testing device for sulfur deposition in sour natural gas gathering and transportation pipelines

A test device and sulfur deposition technology, applied in the direction of analysis materials, instruments, etc., can solve the problems of control, large human error, and the inability to realize the concentration of sulfur particles, etc., and achieve the effects of intuitive experimental results, good safety performance, and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described below with reference to this embodiment. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

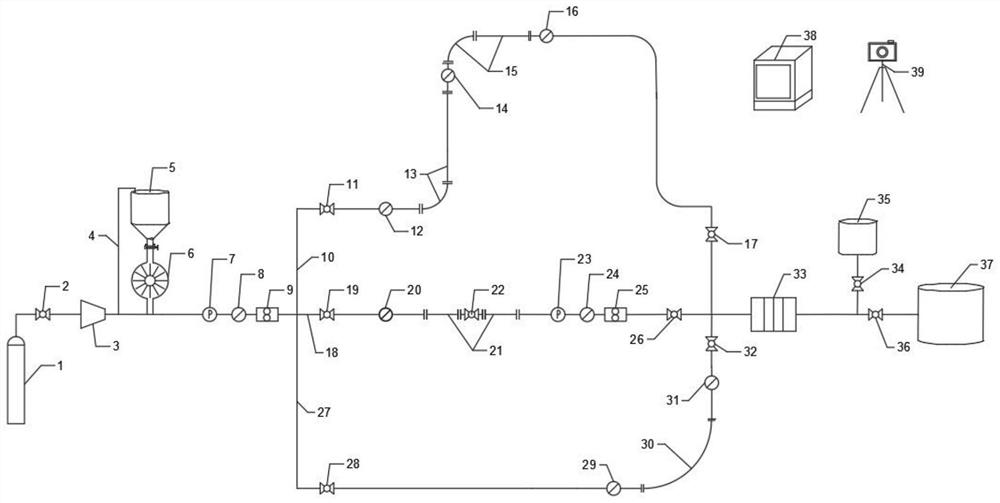

[0017] like figure 1 , figure 2 As shown in the figure, a sulfur deposition test device for a sulfur-containing natural gas gathering and transportation pipeline includes a supply system, a sulfur deposition test system, a data image acquisition system, and a tail gas recovery system.

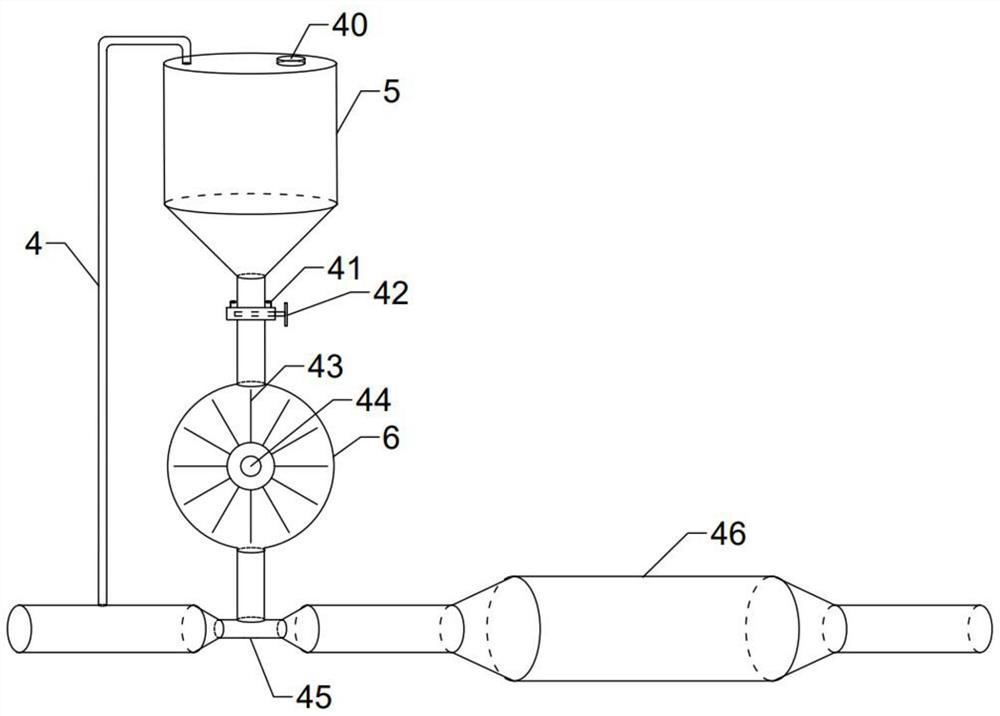

[0018] The supply system includes a gas cylinder 1, a valve A2, a compressor 3, a pressure supplement pipe 4, a sulfur particle storage tank 5, and a uniform feeder 6; the gas cylinder 1 is connected in series with the valve A2, the compressor 3, the Uniform feeder 6; the pressure supplementary pipe 4 is located between the compressor 3 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com