Welding seam automatic identification anti-bending device

A technology of automatic identification and visual identification, applied in the direction of measuring device, testing material strength by applying stable bending force, testing material strength by applying repetitive force/pulsating force, etc., can solve problems such as inability to guarantee the accuracy of test results, and achieve The effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

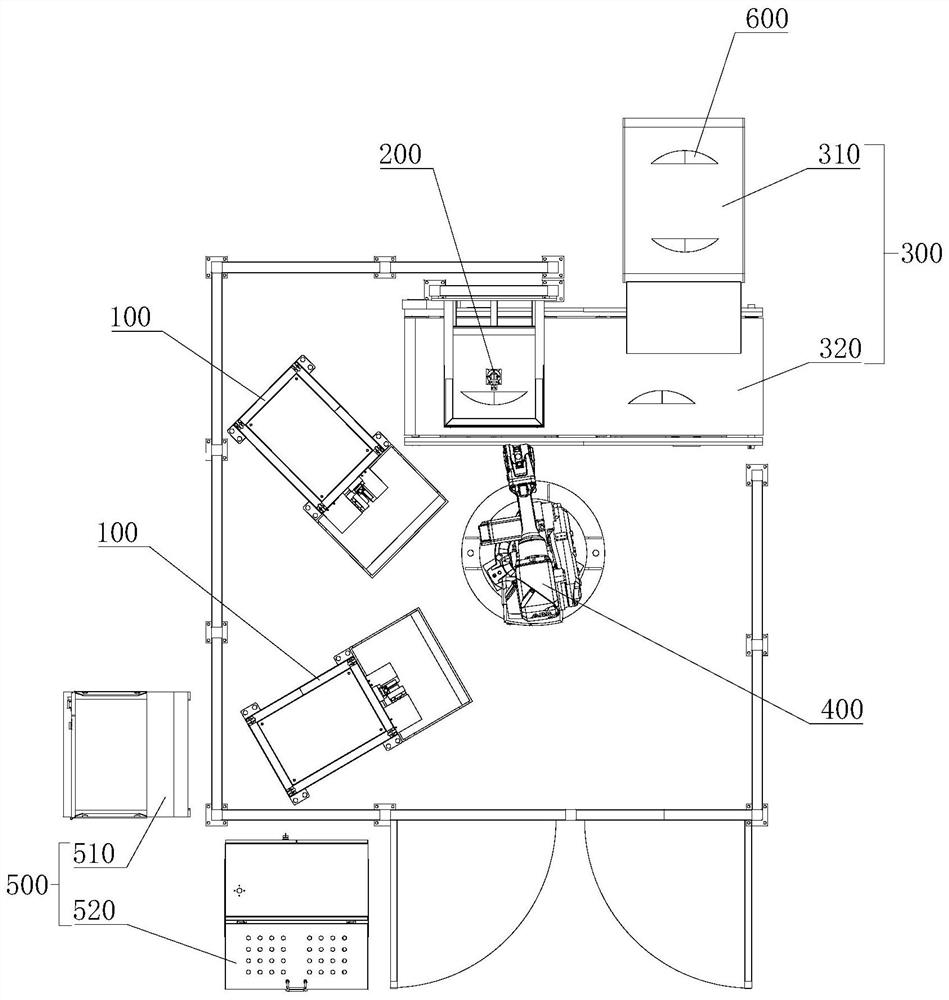

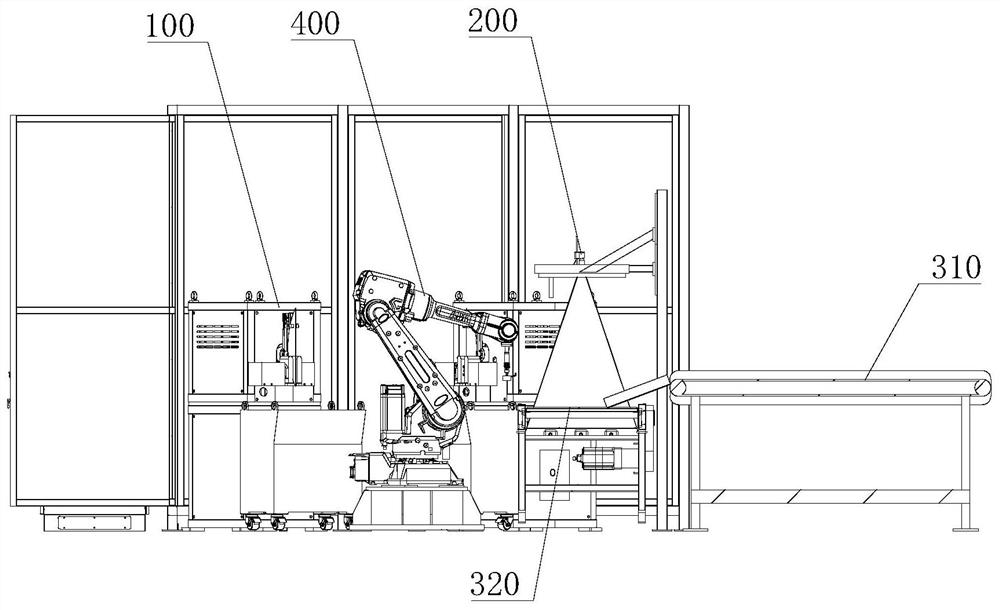

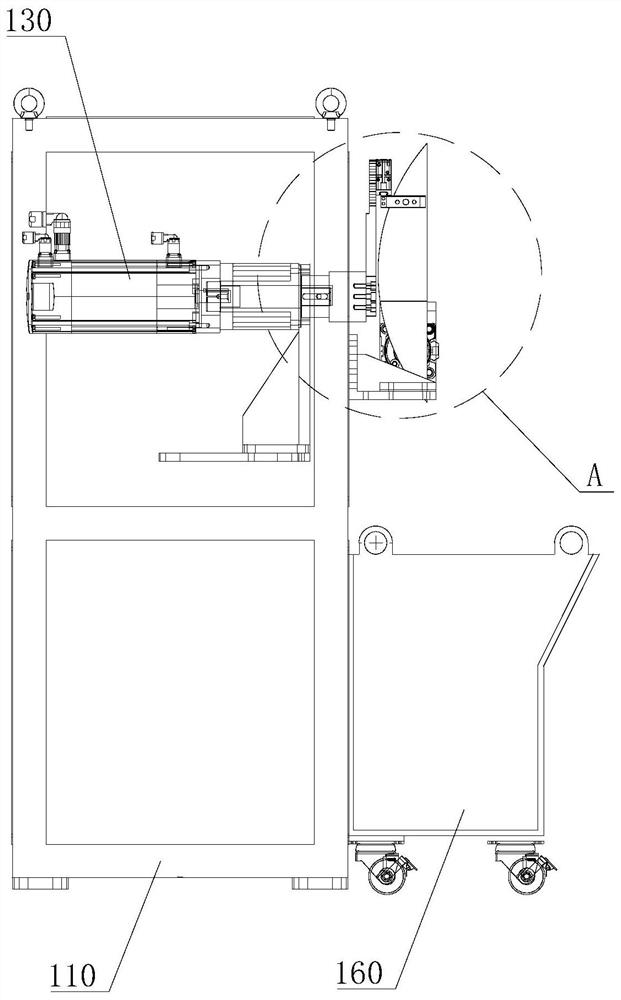

[0041] Please also refer to Figure 1 to Figure 4 , the present embodiment provides an automatic weld recognition and anti-bending device, which is used to detect a steel plate sample 600 with a weld, thereby indirectly judging whether the strength of the weld between adjacent steel coils meets the requirements. The welding seam automatic recognition and bending device includes a control system 500, a conveying system 300, a grabbing robot 400, a visual recognition system 200, a bending machine 100 and an automatic detection system. Among them, the conveying system 300 transports the steel plate sample 600, the grasping robot 400 cooperates with the visual recognition system 200 to transfer the steel plate sample 600 to the bending machine 100 in a suitable posture, and the bending machine 100 cooperates with the automatic detection system to complete the detection process.

[0042] Specifically, the control system 500 is composed of a robot control cabinet 510 and an electric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com