Split type electric control silicone oil clutch water pump

A silicone oil clutch, split-type technology, applied in the direction of clutches, magnetic drive clutches, non-mechanical drive clutches, etc., can solve the problems of increased clutch coupling and separation response time, impeller failure, and increased product scrap rate, etc., to achieve improved responsiveness , reduce the risk of sticking, and improve the effect of assembly methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

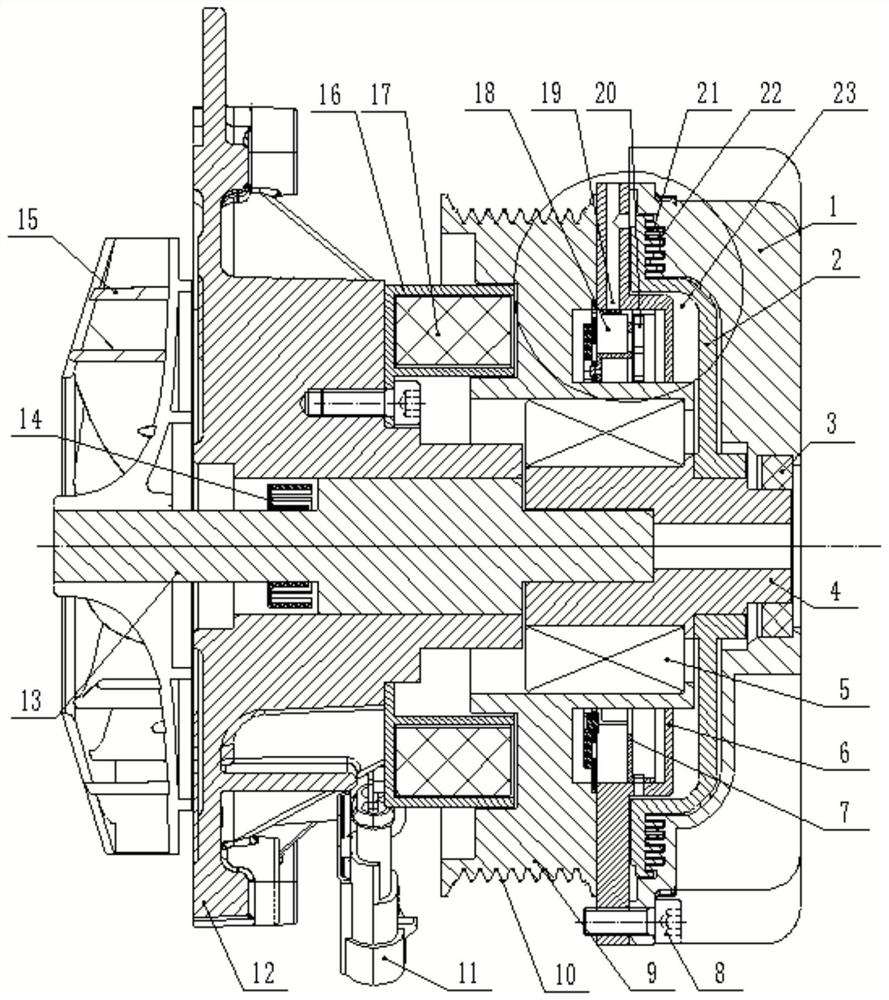

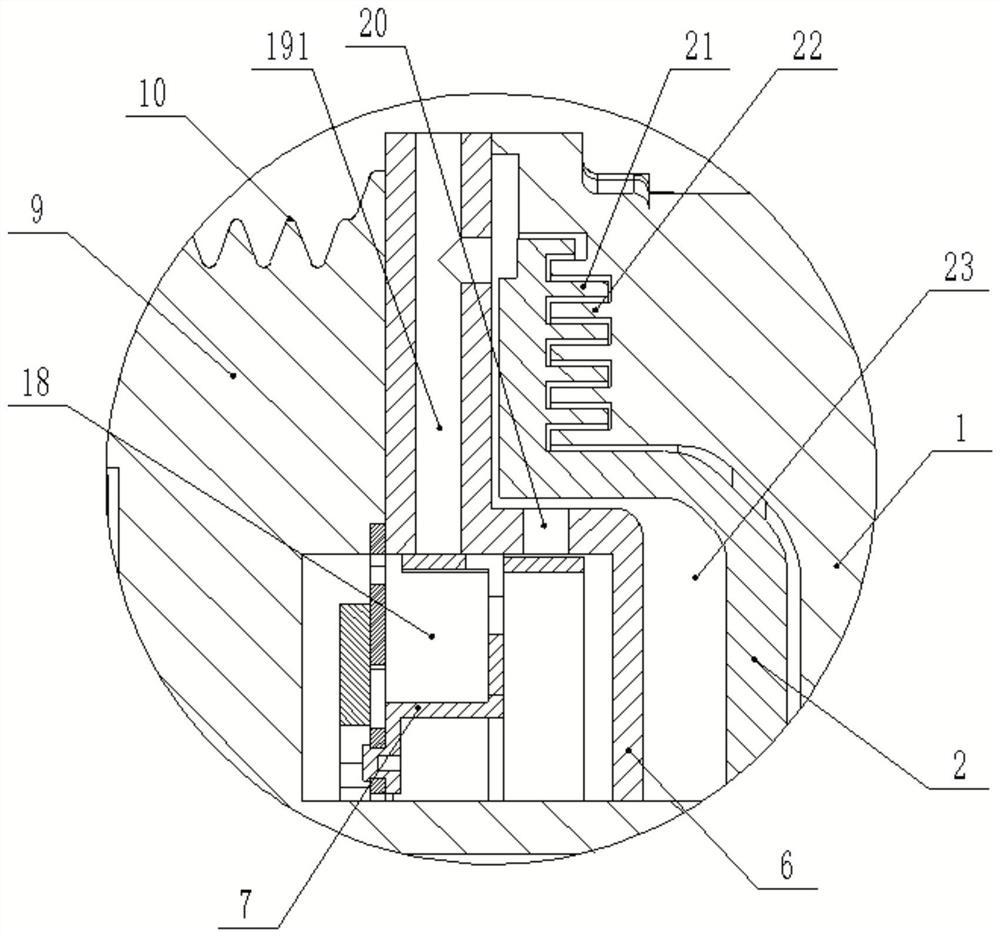

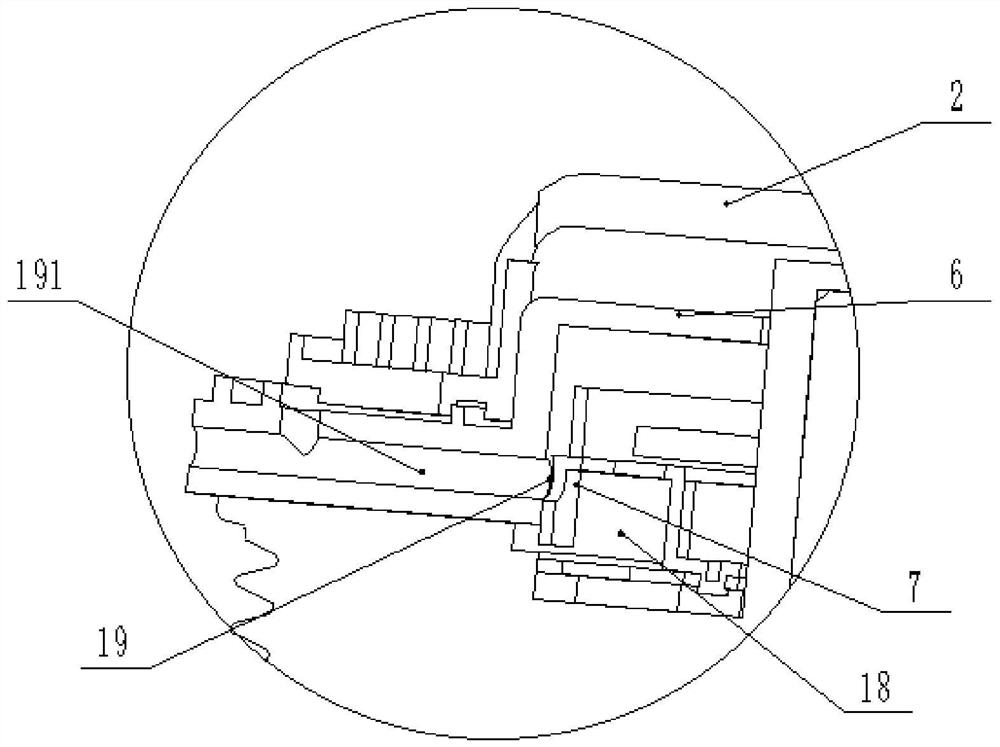

[0036] When the temperature of the engine increases or decreases, the signal sent by the temperature sensor on the engine is collected by the automobile ECU, and the automobile ECU transmits the temperature signal to the electronic control system of the electric water pump clutch. The control system control coil 17 is energized to control the switching action of the valve plate assembly 7. like figure 2 , image 3As shown, when the oil outlet 20 is opened, the oil return port 19 is closed by the valve plate assembly 7. When the belt pulley 9 connected with the engine gear train rotates, relying on the centrifugal force, the silicone oil in the oil storage chamber 18 is released from the oil outlet. The mouth 20 enters, passes through the engagement of the tooth groove 21 of the driven plate and the tooth groove 22 of the upper cover, and enters the working chamber 23. The tooth groove 21 of the driven plate interacts with the tooth groove 22 of the upper cover, and the drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com