Waterproof cable working well

A technology for waterproof cables and wells, which is applied in the field of cable wells, which can solve the problems of waste of sealing materials, time-consuming and laborious maintenance operations, etc., and achieve the effects of reducing working hours, preventing the spread of groundwater, and preventing groundwater backflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

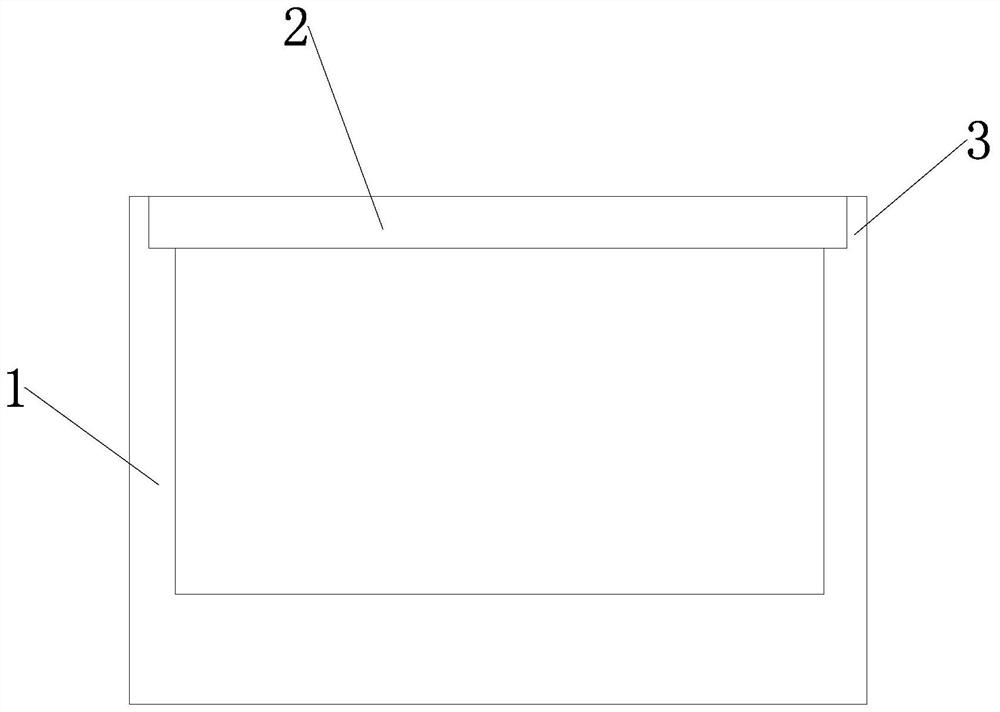

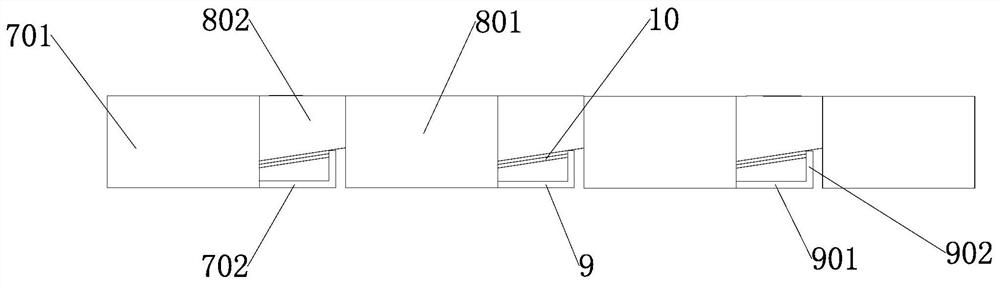

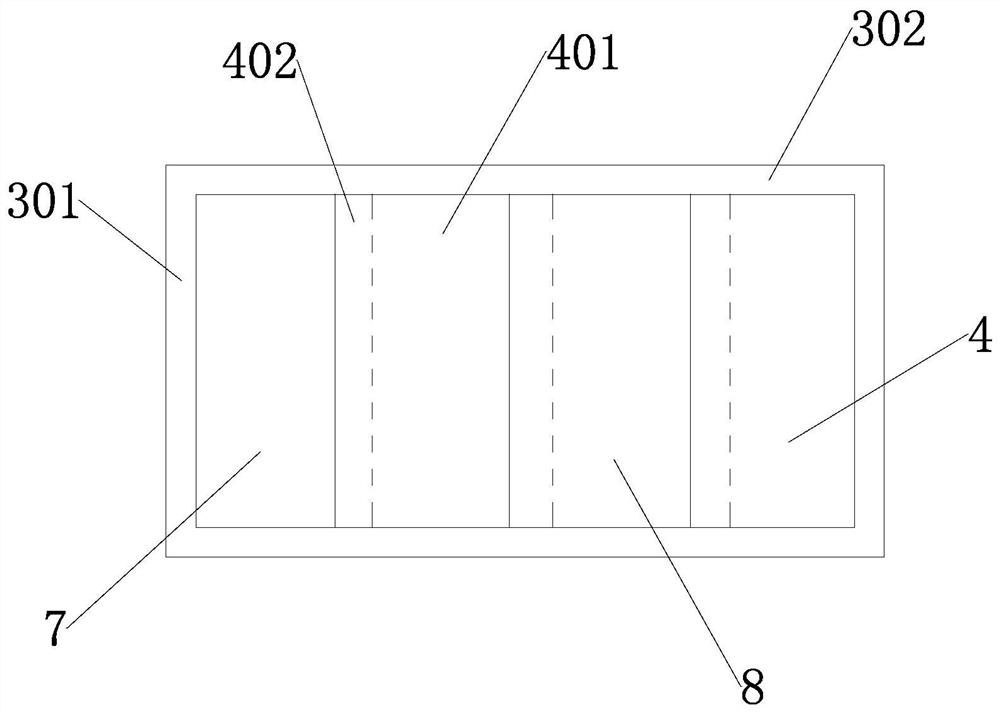

[0031] Such as Figure 1 to Figure 5As shown, a waterproof cable well includes a well body 1 and a well cover 2. The opening end of the well body is provided with a well edge 3 for supporting the well cover. The well cover includes several spliced and matched cover plates 4. The cover plate includes The main body 401 and the supporting member 402, and the two supporting members with similar positions on the adjacent two cover plates are overlapped up and down, and the edge of the working well is provided with a water accumulation groove 5 and a drainage hole 6, and a water collecting well is provided in the working well body. The bottom of the water collection well is provided with a sealing layer; the cover plate includes an end cover plate 7 and a middle cover plate 8, and the end cover plate includes a first body 701 and a first support member 702, and the first support member is located at the first body away from the working well. On one side of the edge, the middle cov...

Embodiment 2

[0035] In this embodiment, a locking piece is added between the end cover plate and the edge of the well to improve the anti-theft protection of the cable. The traditional locking piece adopts an open lock structure. Although the above-mentioned locking piece is easy to open, the anti-theft function of the well cover has declined. In order to enhance the anti-theft function of the manhole cover, this embodiment provides a built-in lock structure, the locking member is arranged between the end cover plate and the edge of the work well, and the first lock groove 11 is opened on the right end surface of the first body, and the edge of the work well There is a second lock groove 12 on the top. When the end cover is in the closed state, the first lock groove and the second lock groove are aligned. The locking part includes a lock cylinder 13, a limiting part 14, a reset part 15 and a reset airbag 16. The lock cylinder includes a lock cylinder body 131 on the left side and a slider ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com