Method for treating collapsible loess foundation through combination of deep pre-soaking method and shallow compaction method

The technology of collapsible loess and pre-soaking water is applied in soil protection, foundation structure engineering, sheet pile wall and other directions, which can solve the problems of low bearing capacity after treatment, long construction period, limited depth of pre-soaking water method, etc. Achieve the effect of shortening the construction period, improving the bearing capacity of the foundation, and accelerating the drainage consolidation rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings and through specific embodiments.

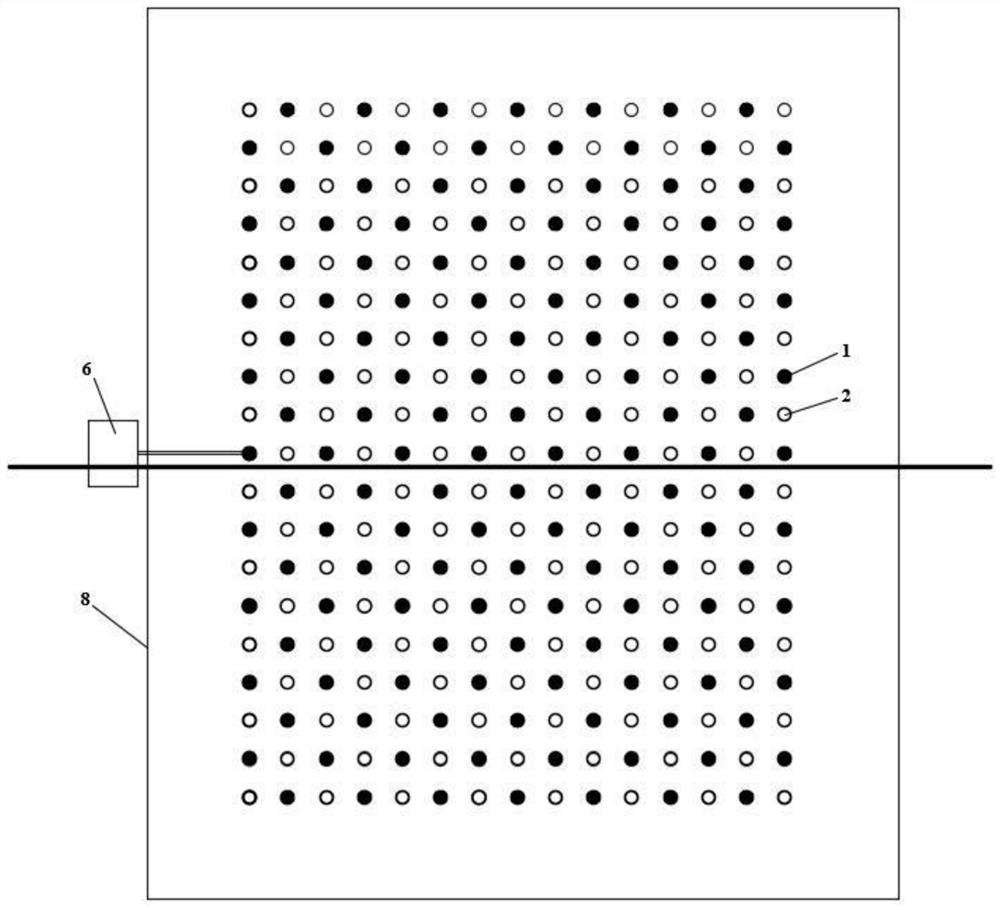

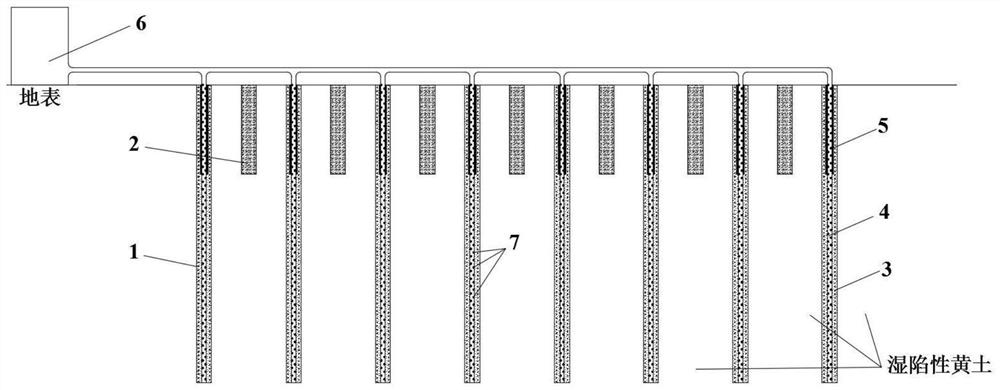

[0030] Refer to attached figure 1 , 2 , the object of the present invention is to provide the method for processing collapsible loess foundation by deep layer pre-soaking method combined with shallow layer compaction method, concrete operation steps are as follows:

[0031] S1. Determine the treatment depth and treatment range for all or part of the loess foundation collapsible elimination based on survey data and design requirements. The foundation treatment shall be adopted for Category A buildings. For self-weight collapsible loess sites, the collapsible loess layer below the foundation bottom shall be completely treated. The foundation treatment measures for Category B and C buildings shall eliminate part of the subsidence of the foundation. For specific requirements, see "Building Standards for Collapsib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com