A kind of mold release agent for building aluminum formwork and using method thereof

A release agent and aluminum formwork technology, applied in lubricating compositions, petroleum industry, etc., can solve problems such as uneven surface of sprayed plastic protective layer or aluminum formwork, easy sticking to cement, poor effect, etc., to reduce building losses , good smoothness, low VOC content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

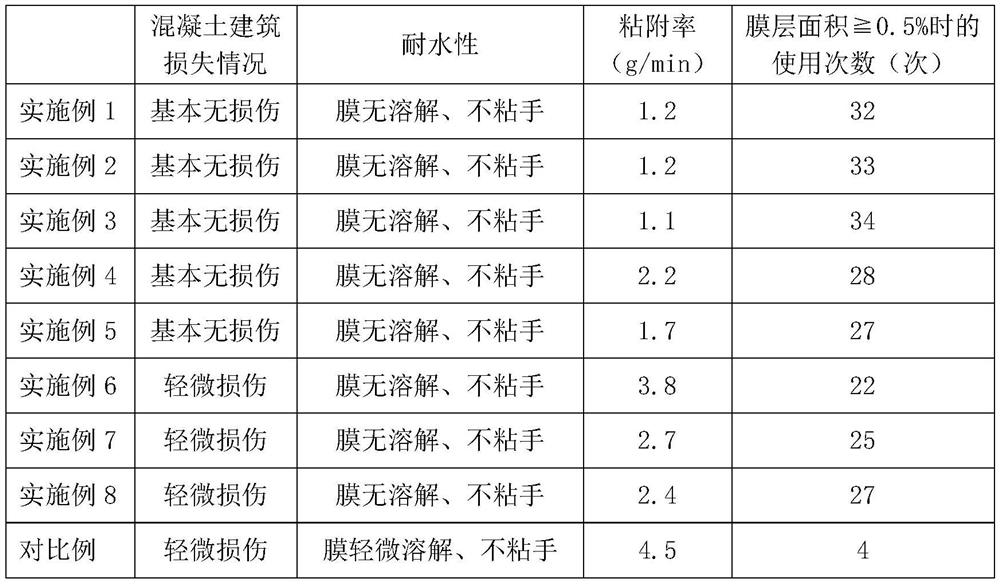

Examples

preparation example Construction

[0025] In one embodiment, the preparation method of the mold release agent for building aluminum formwork comprises the following steps:

[0026] Preparation of component A: Mix the polyurethane resin, multifunctional auxiliary, wax auxiliary and defoamer evenly, then add the remaining raw materials and mix evenly to obtain component A.

[0027] In one embodiment, the weight ratio of the A component to the B component is (10-12):1; further preferably, the weight ratio of the A component to the B component is 11.5:1.

[0028] When using, mix the A component and the B component evenly before use.

[0029] Polyurethane resin

[0030] In one embodiment, the polyurethane resin is an aliphatic polyether polyol type waterborne polyurethane.

[0031] In one embodiment, the aliphatic polyether polyol type waterborne polyurethane has a viscosity pH of 6-8; further preferably, the aliphatic polyether polyol type waterborne polyurethane has a pH value of 7.4.

[0032] In one embodimen...

Embodiment 1

[0079] Embodiment 1 of the present invention provides a mold release agent for building aluminum formwork, the mold release agent is composed of A component and B component, and the preparation raw materials of the A component include, in parts by weight, 60 parts of polyurethane resin, 0.5 part of multifunctional auxiliary, 0.65 part of wetting agent, 11 parts of wax auxiliary, 0.05 part of antibacterial agent, 0.5 part of defoamer, 0.12 part of thickener; the B component includes isocyanate curing agent ;

[0080] The preparation method of the mold release agent for building aluminum formwork comprises the following steps:

[0081] Preparation of component A: Mix the polyurethane resin, multifunctional auxiliary, wax auxiliary and defoamer evenly, then add the remaining raw materials and mix evenly to obtain component A;

[0082] In one embodiment, the weight ratio of the A component to the B component is 10:1;

[0083] The polyurethane resin is an aliphatic polyether poly...

Embodiment 2

[0093] Embodiment 2 of the present invention provides a mold release agent for building aluminum formwork, the mold release agent is composed of A component and B component, and the preparation raw materials of the A component include, in parts by weight, 70 parts of polyurethane resin, 0.6 part of multifunctional auxiliary, 0.8 part of wetting agent, 14 parts of wax auxiliary, 0.08 part of antibacterial agent, 0.7 part of defoamer, 0.14 part of thickener; the B component includes isocyanate curing agent ;

[0094] The preparation method of the mold release agent for building aluminum formwork comprises the following steps:

[0095] Preparation of component A: Mix the polyurethane resin, multifunctional auxiliary, wax auxiliary and defoamer evenly, then add the remaining raw materials and mix evenly to obtain component A;

[0096] In one embodiment, the weight ratio of the A component to the B component is 12:1;

[0097] The polyurethane resin is an aliphatic polyether polyo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com