Preparation method and application of shape memory hydrogel

A technology of hydrogel and cross-linked hydrogel, which is applied in the direction of manufacturing tools, program-controlled manipulators, manipulators, etc., to achieve the effects of fast deformation speed, high energy density, ultra-high elongation at break and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

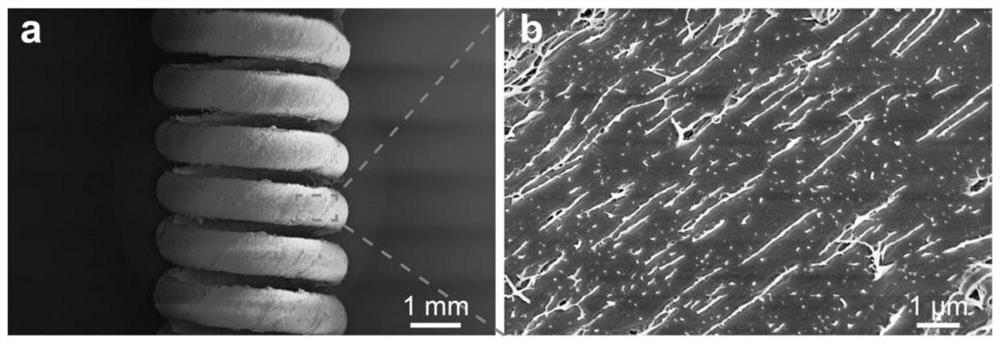

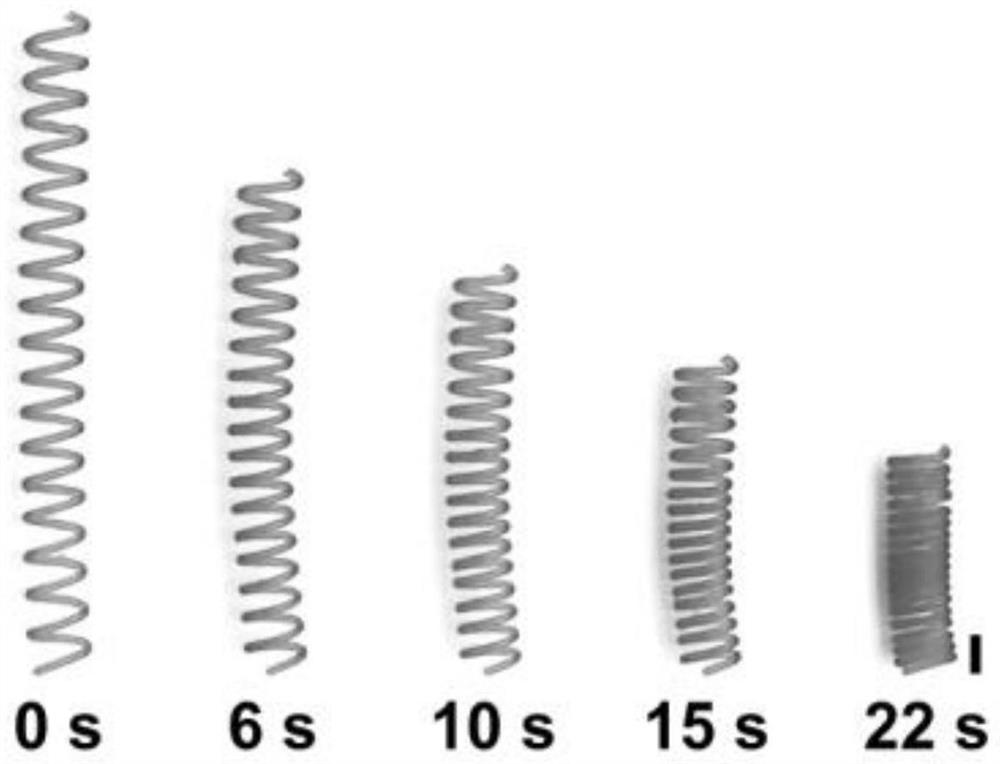

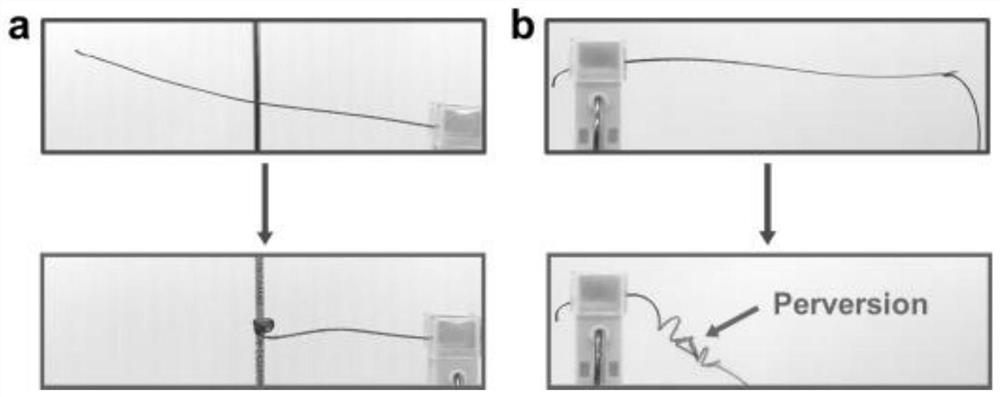

[0028] A monocrosslinked hydrogel was prepared by dissolving acrylic acid, acrylamide and acrylamide adamantane in the aqueous dispersion of cyclodextrin-grafted ascidian cellulose nanocrystals. The hydrogel is stretched by 1600% stretching ratio, 469 turns / m twisting density twisting and counterclockwise helical winding on the 3mm pipe, soaked in ferric chloride solution to obtain the hydrogel muscle. Its shrinkage rate in ethanol is -13.7% / s, the shrinkage strain is -65%, and the maximum energy density is 1.6J / kg.

Embodiment 2

[0030] A monocrosslinked hydrogel was prepared by dissolving acrylic acid, acrylamide and acrylamide adamantane in the aqueous dispersion of cyclodextrin-grafted ascidian cellulose nanocrystals. The hydrogel is stretched by 1600% stretching ratio, 469turns / m twisting density twisting and clockwise helical winding on the 3mm pipe, soaked in ferric chloride solution to obtain the hydrogel muscle. Its shrinkage rate in ethanol is 17.9% / s, the shrinkage strain is 473%, and the maximum energy density is 11.8J / kg.

Embodiment 3

[0032] A monocrosslinked hydrogel was prepared by dissolving acrylic acid, acrylamide and acrylamide adamantane in the aqueous dispersion of cyclodextrin-grafted ascidian cellulose nanocrystals. The hydrogel is stretched by 1600% stretching ratio, 469turns / m twisting density twisting and clockwise helical winding on the 3mm pipe, soaked in ferric chloride solution to obtain the hydrogel muscle. After the hydrogel was elongated and fixed to the hydrogel temporary shape in ethanol, its shrinkage strain in water was determined to be -87%, and the maximum energy density was 42.4 J / kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum energy density | aaaaa | aaaaa |

| Maximum energy density | aaaaa | aaaaa |

| Maximum energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com