Industrial fermentation wastewater treater

A fermentation wastewater and processor technology, applied in biological water/sewage treatment, adsorbed water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problem of particle adhesion, reduce fermentation wastewater treatment efficiency, and high viscosity of suspended particles problem, to achieve the effects of good flocculation, improved transparency, and good resistance reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

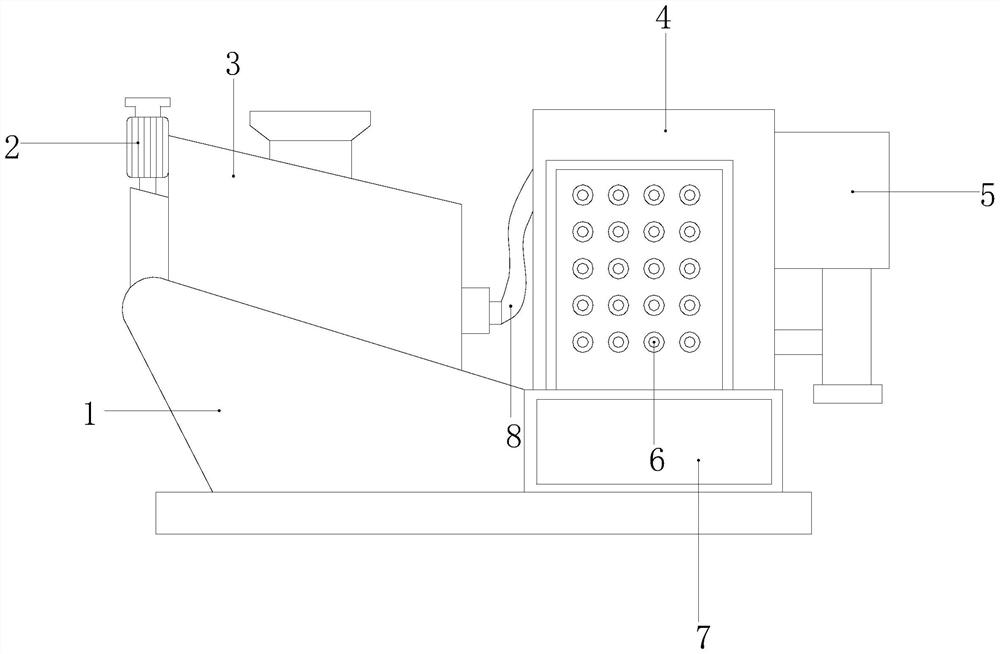

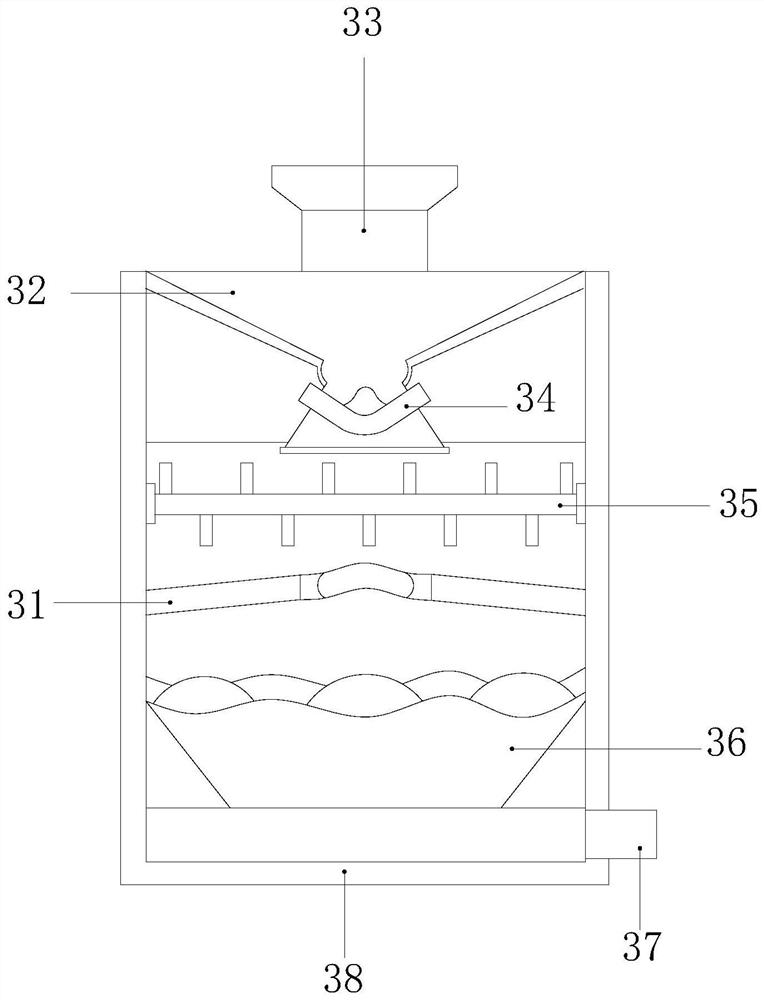

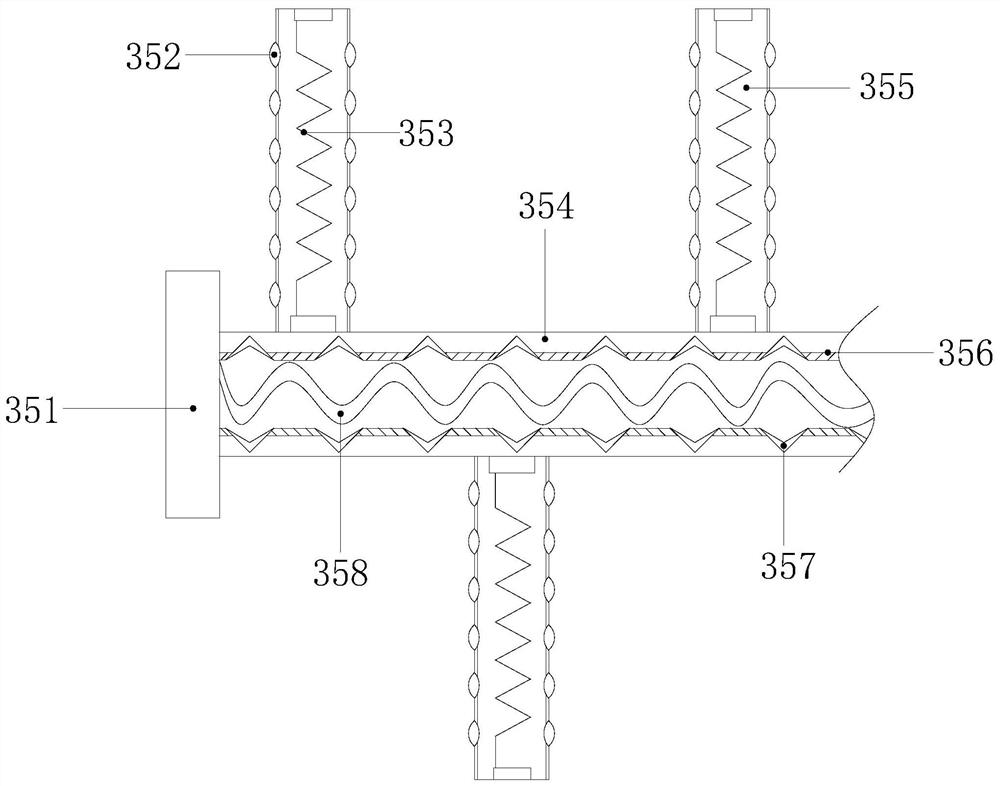

[0030] see figure 1 , the present invention provides a technical solution: an industrial fermentation wastewater processor, the structure of which includes a fixed seat 1, a motor 2, a processing device 3, a disinfection chamber 4, an outlet pipe 5, an electric control box 6, a frame 7, and a conduit 8 , the fixed seat 1 is vertically installed on the frame 7, the end of the fixed seat 1 away from the frame 7 is provided with a processing device 3 and the two are fixedly connected, and the fixed seat 1 is on the side facing the processing device 3 A motor 2 is installed, and the motor 2 is connected with the electric control box 6 by wires, the electric control box 6 is vertically fixed on the frame 7, the back of the electric control box 6 is attached to the disinfection cavity 4, and the disinfection The chamber 4 is connected to the treatment device 3 through a conduit 8, and the side of the disinfection chamber 4 away from the conduit 8 is provided with an outlet pipe 5 c...

Embodiment 2

[0041] see figure 1 , the present invention provides a technical solution: an industrial fermentation wastewater processor, the structure of which includes a fixed seat 1, a motor 2, a processing device 3, a disinfection chamber 4, an outlet pipe 5, an electric control box 6, a frame 7, and a conduit 8 , the fixed seat 1 is vertically installed on the frame 7, the end of the fixed seat 1 away from the frame 7 is provided with a processing device 3 and the two are fixedly connected, and the fixed seat 1 is on the side facing the processing device 3 A motor 2 is installed, and the motor 2 is connected with the electric control box 6 by wires, the electric control box 6 is vertically fixed on the frame 7, the back of the electric control box 6 is attached to the disinfection cavity 4, and the disinfection The chamber 4 is connected to the treatment device 3 through a conduit 8, and the side of the disinfection chamber 4 away from the conduit 8 is provided with an outlet pipe 5 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com