Self-adaptive discharge pipeline for chemical sewage

A chemical sewage, self-adaptive technology, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Suspended solids removal, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

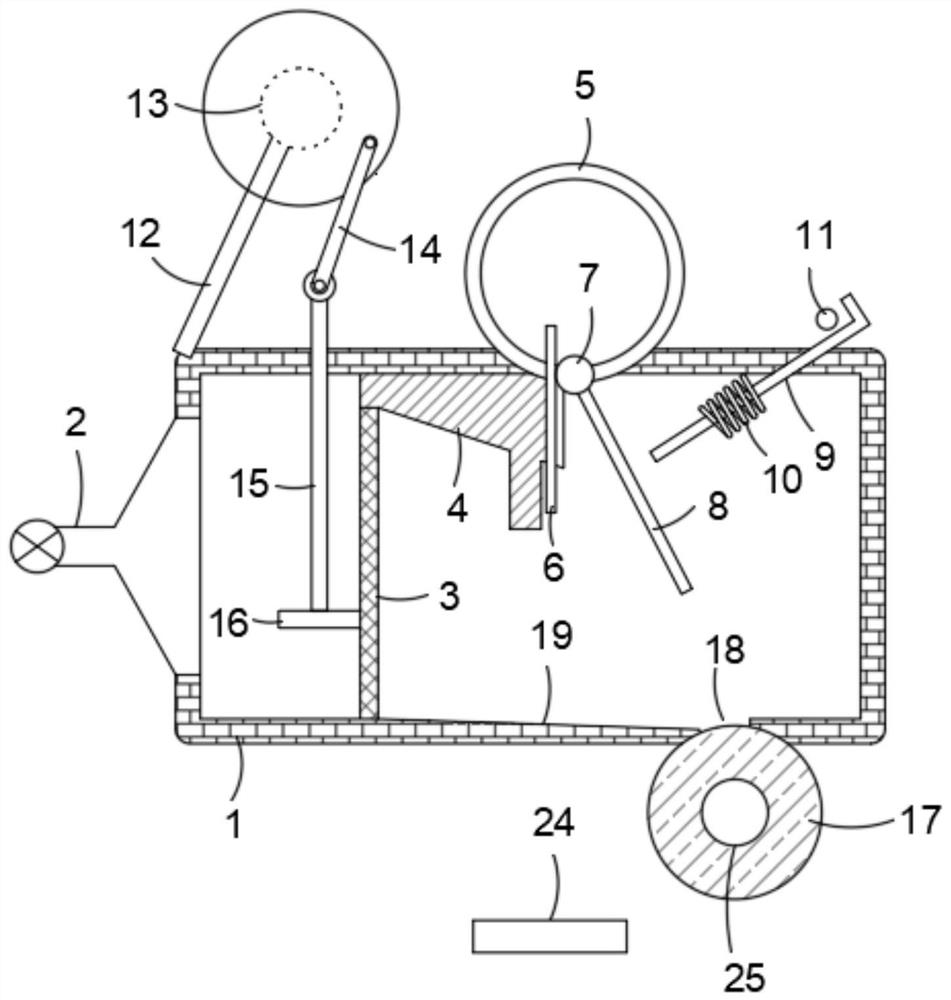

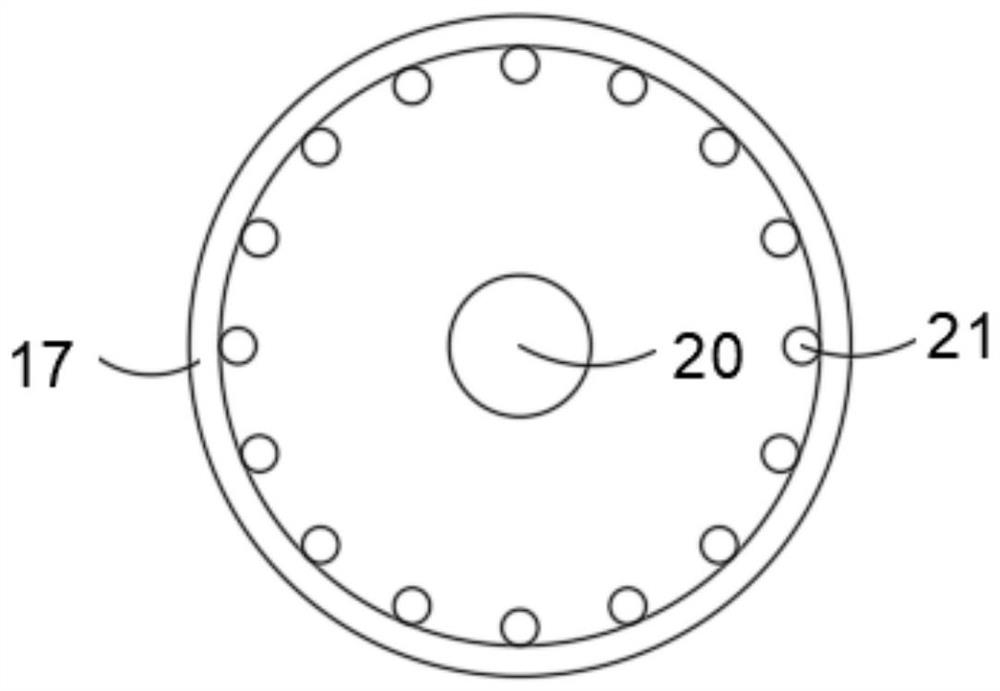

[0024] Refer Figure 1-2 A chemical sewage adaptive discharge pipe, including the tubular body 1, the end portion of the tubular body 1 is provided with an inlet port 2, and the inner top wall of the tubular body 1 is fixedly connected to the stopper 4, the lower side wall and tube of the stopper 4. The upper wall of the body 1 is fixedly connected between the surface, the upper side wall of the tube body 1 is fixedly connected to the storage tank 5, and the lower side wall of the storage tank 5 is mounted with a gear 17, and the outer wall of the gear is fixed. The lower side wall of the tube body 1 is connected to the upper side of the tube 1, and the lower end of the discharge tube 6 is provided, and the outer wall of the discharge tube 6 is in contact with the gear, and The serrations of the gear elevators are opened, and the upper end of the discharge tube 6 is open to the lower end seal, and there is a pan in the outer wall of the discharge tube 6, and the external chemical w...

Embodiment 2

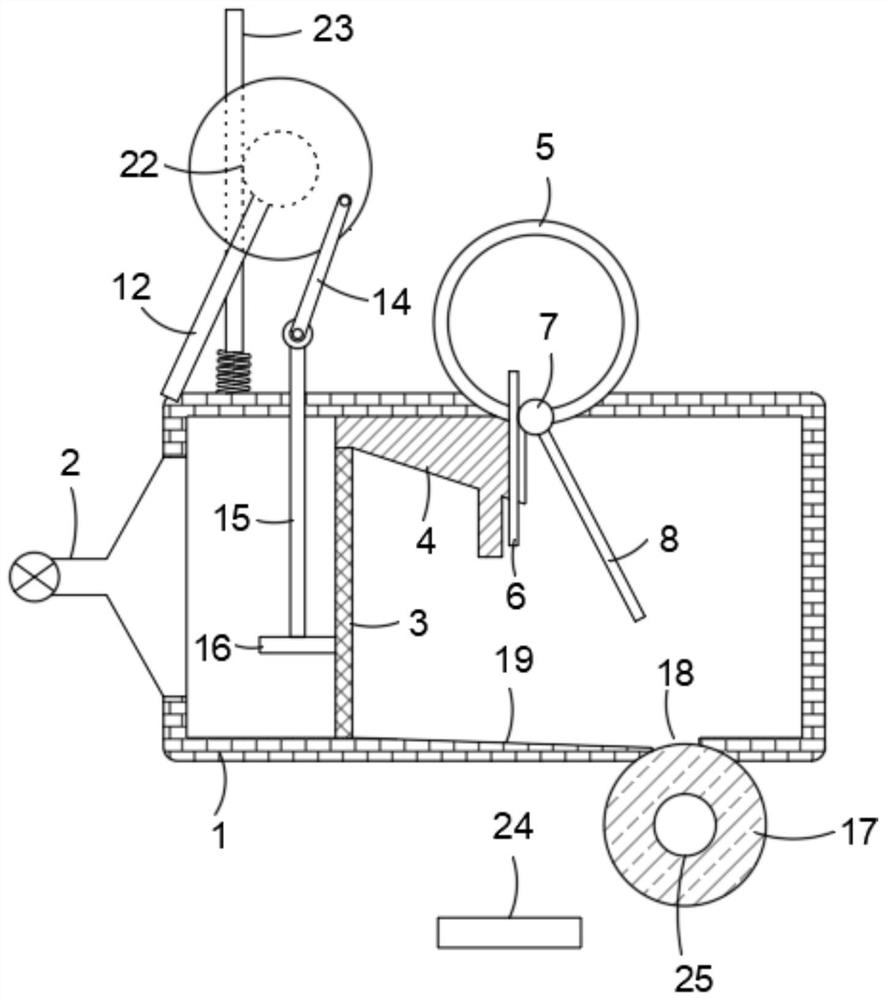

[0028] Refer image 3 Different from one of the examples in:

[0029] The trigger mechanism includes a gear 22 that is fixed to the outer wall of the turntable, and the upper side wall fixing is fixed to the support plate 12, the gear 2 22 is mounted on the upper end of the support plate 12, and the upper side of the tube 1 slides in the upper side of the tube 222 The tooth plate 23, the tooth plate 23 is fixed to the upper side wall of the tubular body 1, and the upper end of the tooth plate 23 can be extended to the road surface, and the upper end of the tooth plate 23 is set to a curved shape, guarantee The vehicle or pedestrian can safely step on the pressed plate 23, and then the jaw 222 and the turntable rotation are rotated by the engagement between the tooth plate 23 and the gear 2 22, and the upper and lower movement of the blade 16 is achieved, and the finishing of the surface of the filter 3 is achieved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com