Knotless screen printing plate based on positioning marks and manufacturing process of kotless screen printing plate

A technology for positioning identification and manufacturing process, applied in the field of solar cells, can solve the problems of low efficiency and yield rate, and achieve the effect of improving the plate-making yield, easy to use, and reducing the plate-making process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

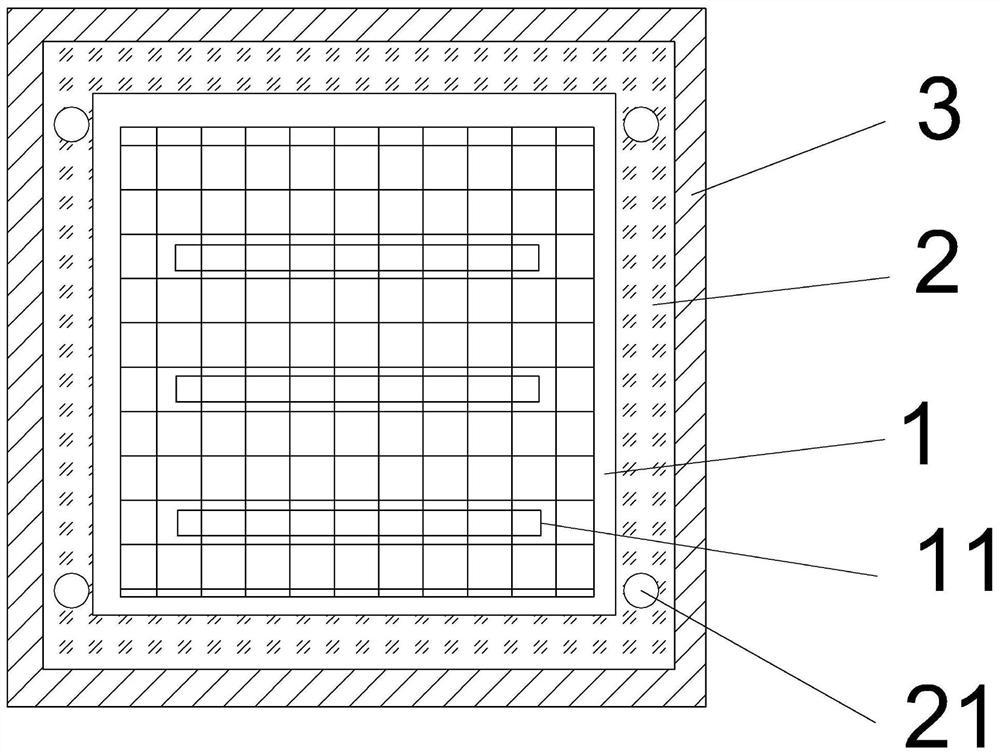

[0030] like figure 1 As shown, a kind of knotless screen plate based on the positioning mark, including the first screen cloth 1 and the second screen cloth 2 arranged in sequence, and the periphery of the second screen cloth 2 is provided with a screen frame 3;

[0031] The first mesh 1 is provided with a line printing area 11 , and the second mesh 2 is pasted with several positioning marks 21 .

[0032] According to another aspect of the present invention, there is provided a manufacturing process of a knotless screen plate based on a positioning mark, comprising the following steps:

[0033] Step S1: composite the first mesh 1 on the second mesh 2, stretch to a certain tension and fix it on the screen frame 3 to form a screen.

[0034] Step S2: Paste the positioning mark 21 outside the graphic preparation area of the screen, and then put the screen into a constant temperature and humidity environment and let it stand for stability.

[0035] Step S3: Put the stabilized s...

Embodiment 2

[0040] like figure 1 As shown, a kind of knotless screen plate based on the positioning mark, including the first screen cloth 1 and the second screen cloth 2 arranged in sequence, and the periphery of the second screen cloth 2 is provided with a screen frame 3;

[0041] The first mesh 1 is provided with a line printing area 11 , and the second mesh 2 is pasted with several positioning marks 21 .

[0042] Further, in another embodiment, the first mesh 1 is one of stainless steel mesh, electroformed mesh or polyester mesh, and the second mesh 2 is stainless steel mesh, polyester mesh One of mesh or nylon mesh.

[0043] Further, in another embodiment, the first mesh cloth 1 is a stainless steel mesh cloth, and the second mesh cloth 2 is a polyester mesh cloth.

[0044] Furthermore, in another embodiment, the number of the positioning marks 21 is 3-4, and the shape is a circle or other polygons.

[0045] Further, in another embodiment, the tension of the first mesh cloth 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com