Pre-wetting equipment, pre-wetting system and pretreatment method for wafer pre-wetting

A pre-wetting, equipment technology, used in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problem that both sides of the wafer cannot be processed at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

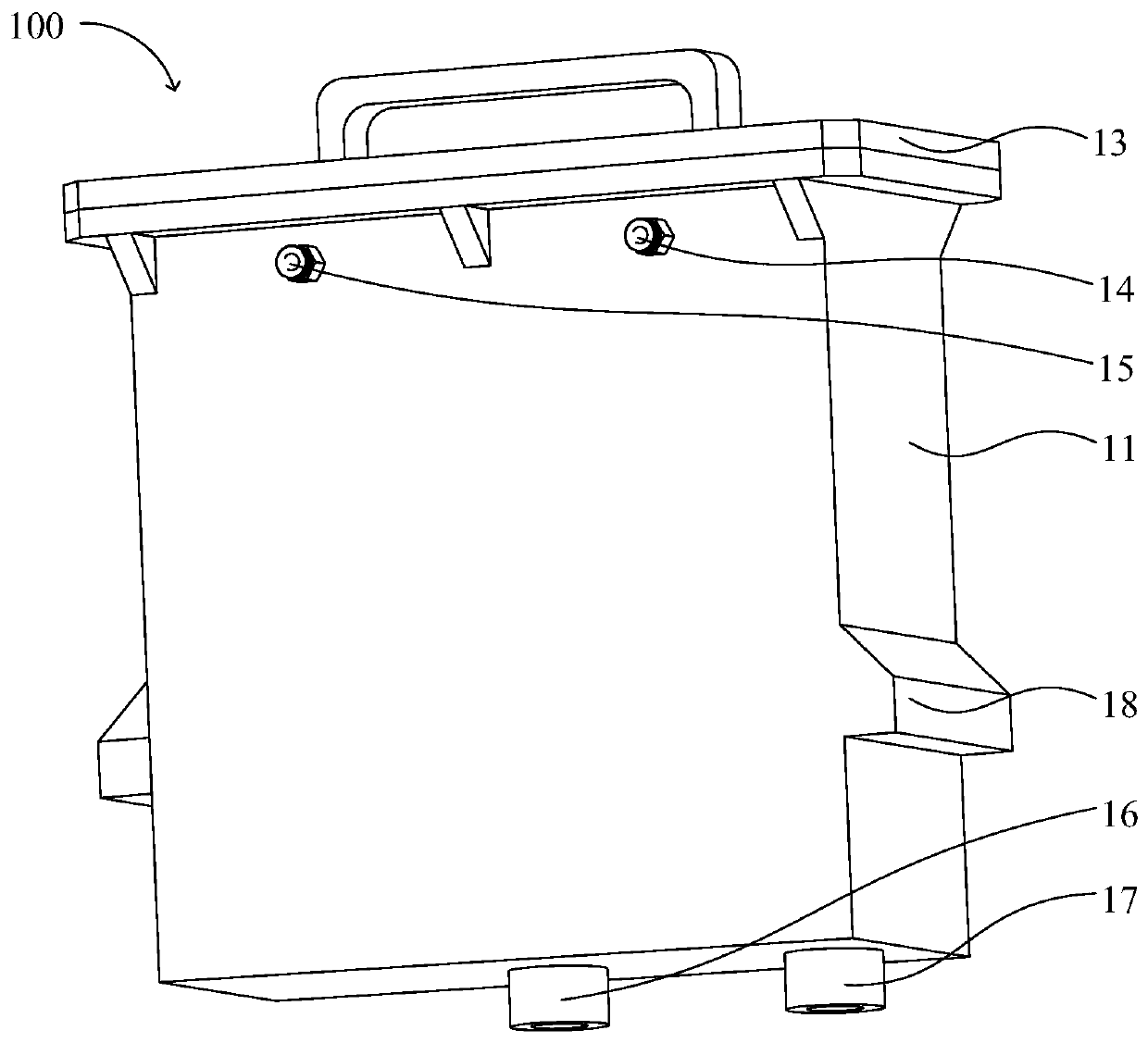

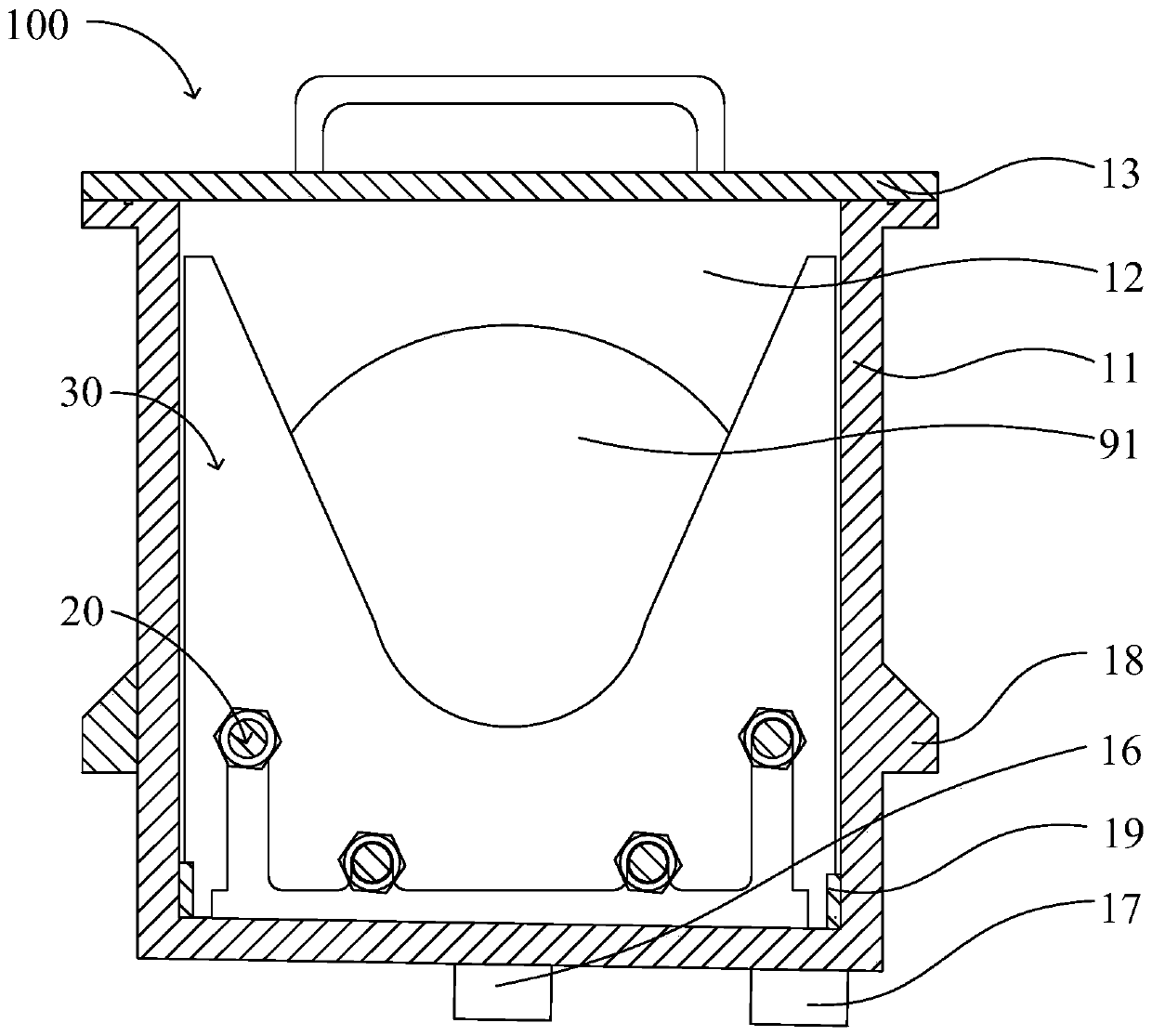

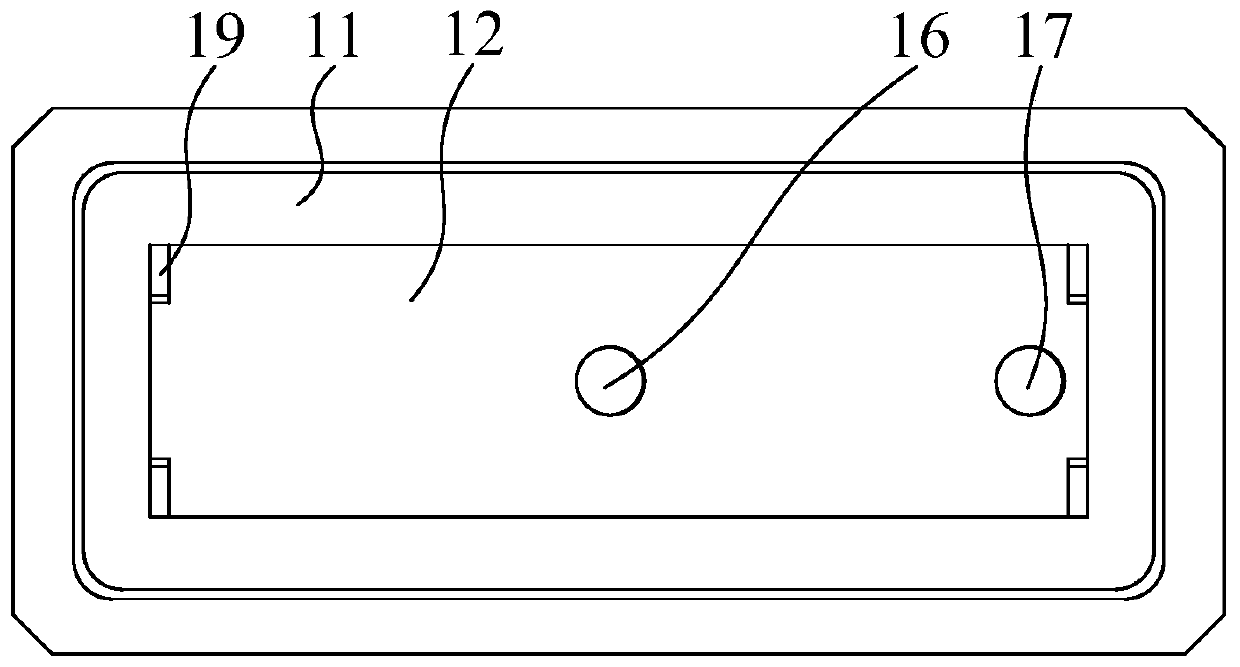

[0131] Such as Figure 1-Figure 6 As shown, the present embodiment is a kind of pre-wetting equipment 100, which is used for pre-wetting of wafer 91. In order to pass through the pre-wetting liquid, the pre-wetting device 100 also includes a clamping part 20, which is arranged inside the accommodating chamber 12, and the clamping part 20 is used to clamp the outer surface of the wafer 91, so as to Wafer 91 is submerged in a pre-wetting liquid. In this embodiment, the wafer 91 is clamped by the clamping part 20 provided in the accommodating chamber 12, and then the pre-wetting liquid is filled into the accommodating chamber 12, thereby immersing the wafer 91 in the pre-wetting liquid, and then Both sides of the wafer 91 can be wetted by the pre-wetting liquid. The pre-wetting equipment 100 of this embodiment has a simple structure, and can achieve wetting of both sides of the wafer 91 at one time, which is beneficial to improving the pre-wetting efficiency of the wafer 91 . ...

Embodiment 2

[0157] Such as Figure 7-Figure 9 As shown, the present embodiment is a pre-wetting system 400, and the pre-wetting system 400 includes the pre-wetting device 100 as in the first embodiment. For ease of description, this embodiment continues to use the reference numerals in Embodiment 1. In this embodiment, by using the pre-wetting device 100 , the two sides of the wafer 91 can be wetted by the pre-wetting liquid at the same time, which is beneficial to improve the pre-treatment efficiency of the pre-wetting of the wafer 91 .

[0158] As a preferred embodiment, the pre-wetting system 400 may also include an air extraction device 41 and a liquid storage tank 50, the air extraction device 41 communicates with the pre-wetting device 100; the liquid storage tank 50 is used to store the pre-wetting Liquid, the liquid storage tank 50 communicates with the pre-wetting device 100 through pipes. In this embodiment, the liquid storage tank 50 is used to provide the pre-wetting liquid,...

Embodiment 3

[0172] Such as Figure 10 As shown, the present embodiment is a pre-wetting pre-treatment method for the wafer 91 , and the pre-wetting system 400 as in the second embodiment is used in the pre-treatment method. For ease of description, this embodiment continues to use the reference numerals in Embodiment 1 and Embodiment 2. In this embodiment, by using the pre-wetting system 400 , the two sides of the wafer 91 can be wetted by the pre-wetting liquid at the same time, which is beneficial to improve the pre-wetting efficiency of the wafer 91 .

[0173] As a preferred embodiment, the pretreatment method may include: S10: Open the first box 11, and put the wafer 91 into the clamping part 20; S20: Put the pre-wetting liquid from the reservoir of the pre-wetting system The liquid tank 50 is transported into the first box 11; S30: the wafer 91 is immersed in the pre-wetting liquid. This embodiment is beneficial to simplify the operation steps of the pre-wet pretreatment of the waf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com