Manufacturing method of resin product

A production method and technology of resin products, which are applied in the field of handicraft manufacturing, can solve the problems of unstable manual production quality and low manual production efficiency, and achieve the effect of solving manual production quality instability, stable quality, and avoiding low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

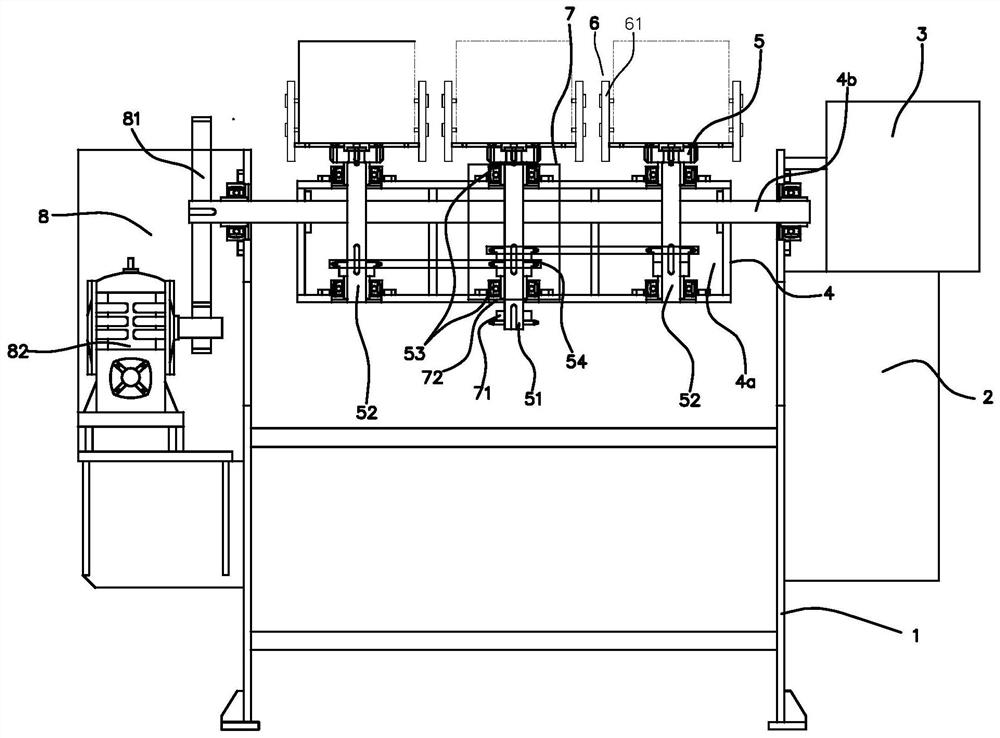

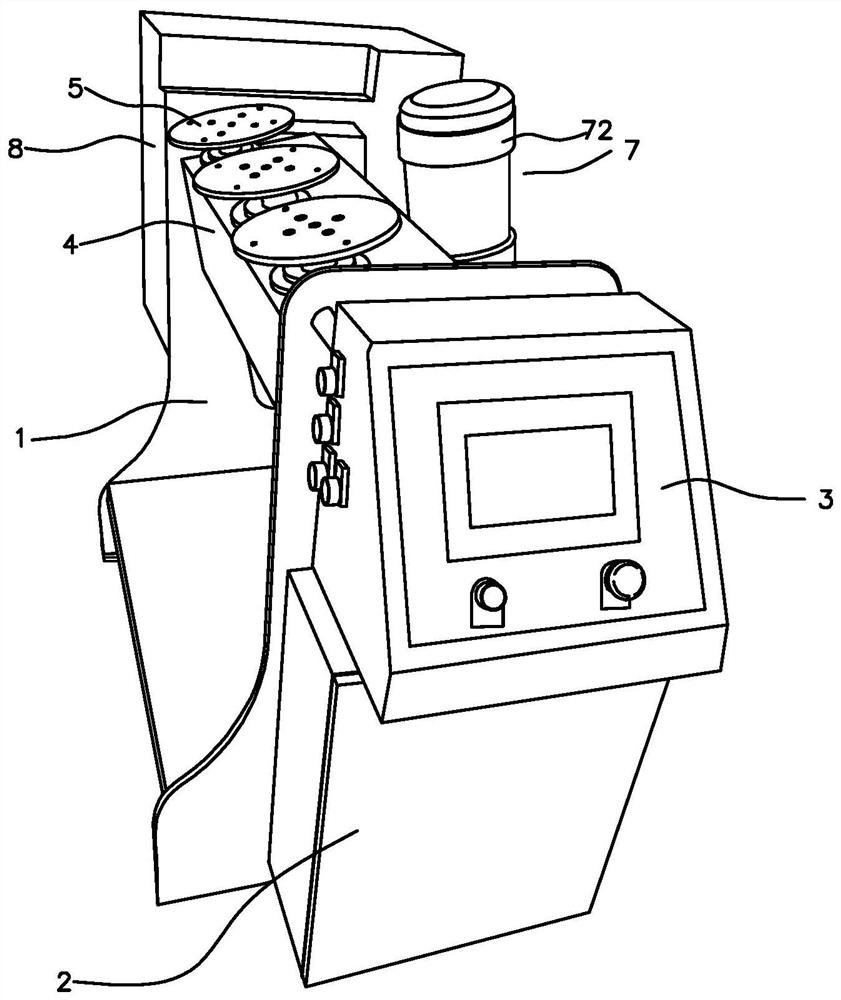

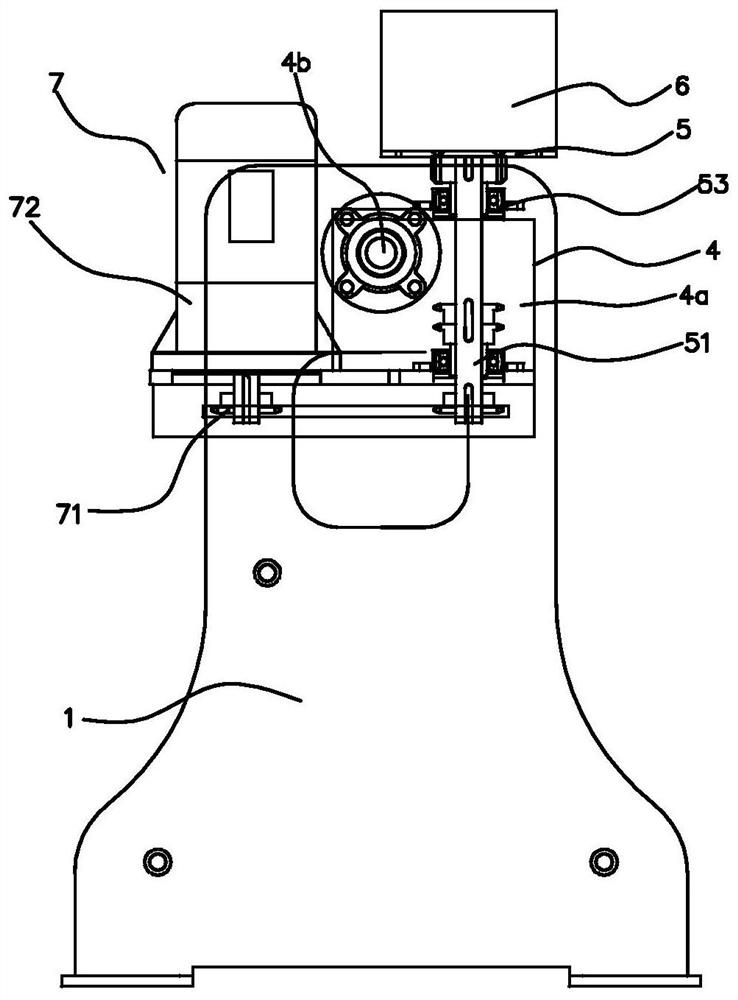

[0045] refer to Figure 1 to Figure 14 The present embodiment provides a kind of manufacturing method of resin product, comprises the following steps:

[0046] The first step: Pour the resin into the injection ports of multiple molding molds on the shaker, then close the injection ports of each molding mold after completion, and place multiple molding molds on the rotating disk of the shaker;

[0047] Step 2: Set and run the console according to the actual usage. After the completion, the shaker runs. The shaker drives multiple forming molds to reciprocate along the horizontal axis according to the set angle, and multiple forming molds rotate in an inclined state. , The shaker then drives each molding mold to rotate along its own center of circle to shake the pulp. Under the action of centrifugal force, the resin in the molding mold is pasted into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com