Automobile waste cutting machine

A technology of cutting machine and cutting mechanism, which is applied in the direction of grain processing, etc. It can solve the problems of affecting the collection effect and troubles, and achieve the effect of improving the separation effect, reducing the impact force, and facilitating processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

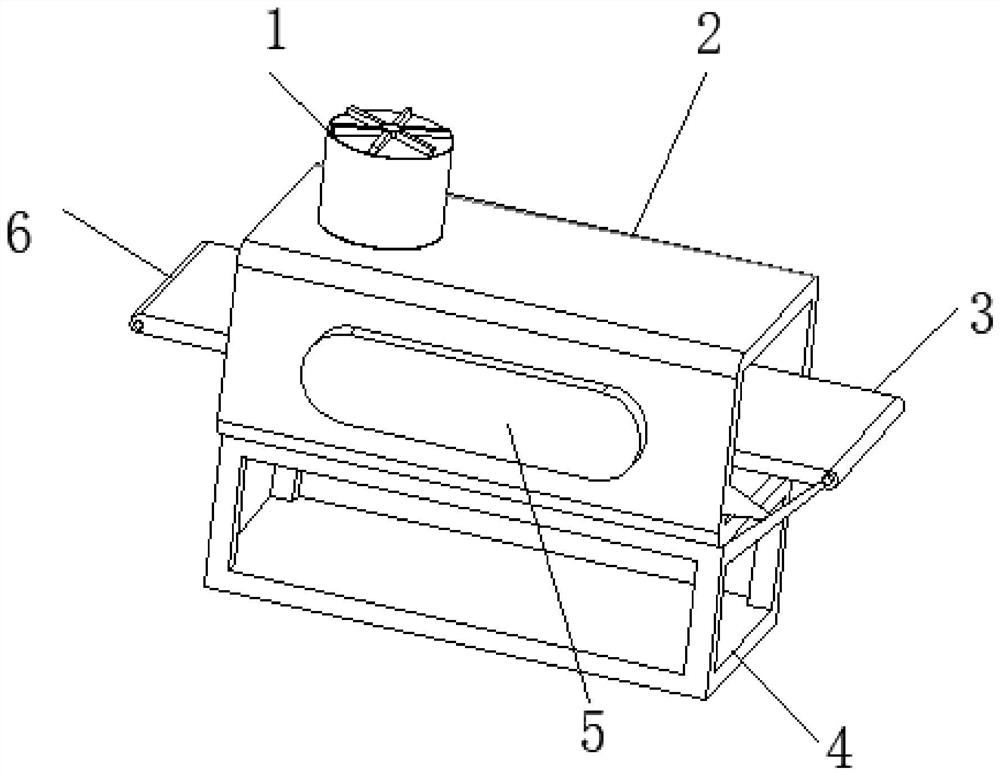

[0028] like Figure 1-6 As shown, the embodiment of the present invention provides an automobile scrap cutting machine, including a negative pressure mechanism 1, a mounting plate 2, a feeding conveyor belt 3, a mounting frame 4, a cutting mechanism 5 and a discharging conveyor belt 6, and is characterized in that: the mounting frame 4 Welded on the bottom outer wall of the installation plate 2, the bottom outer wall of the installation plate 2 is provided with an installation groove, the negative pressure mechanism 1 is set on the inner wall of the installation groove, the feeding conveyor belt 3 is fixedly connected with the inner walls of both sides of the installation plate 2, and the cutting mechanism 5 is set On the inner wall of the mounting plate 2 close to the feed conveyor belt 3 , the discharge conveyor belt 6 is arranged below the discharge part of the cutting mechanism 5 , and the negative pressure mechanism 1 is located above the discharge conveyor belt 6 .

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com