Wood chip collecting and granulating equipment

A technology of pelletizing equipment and wood chips, which is used in the extrusion and pelletization of raw materials, waste fuel, fuel, etc., and can solve problems such as reducing work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

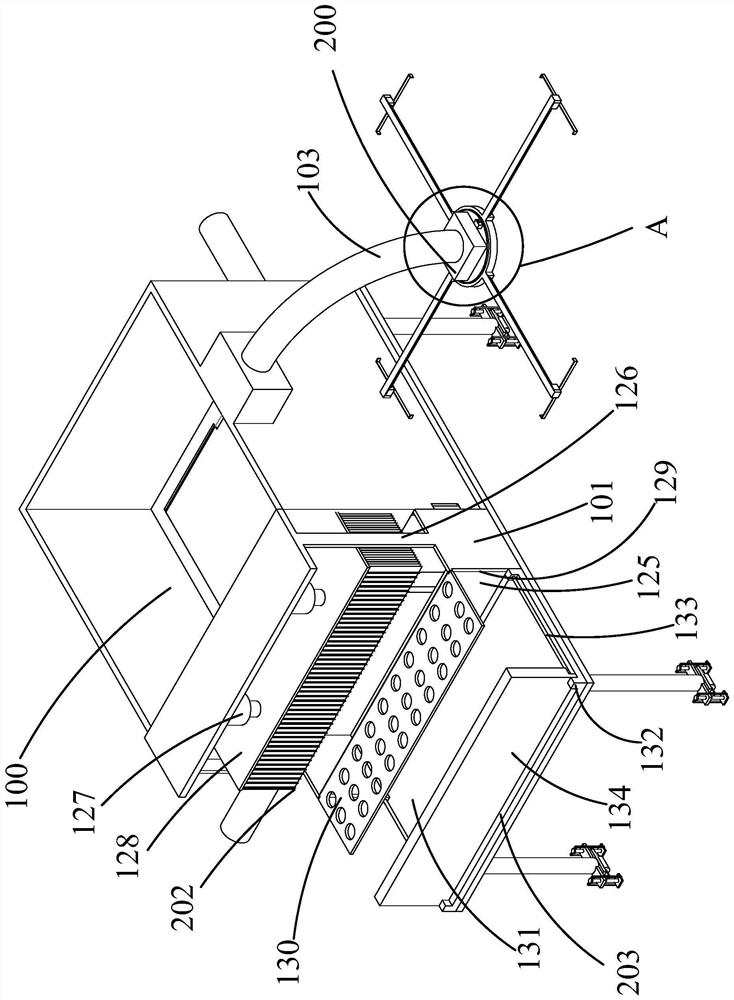

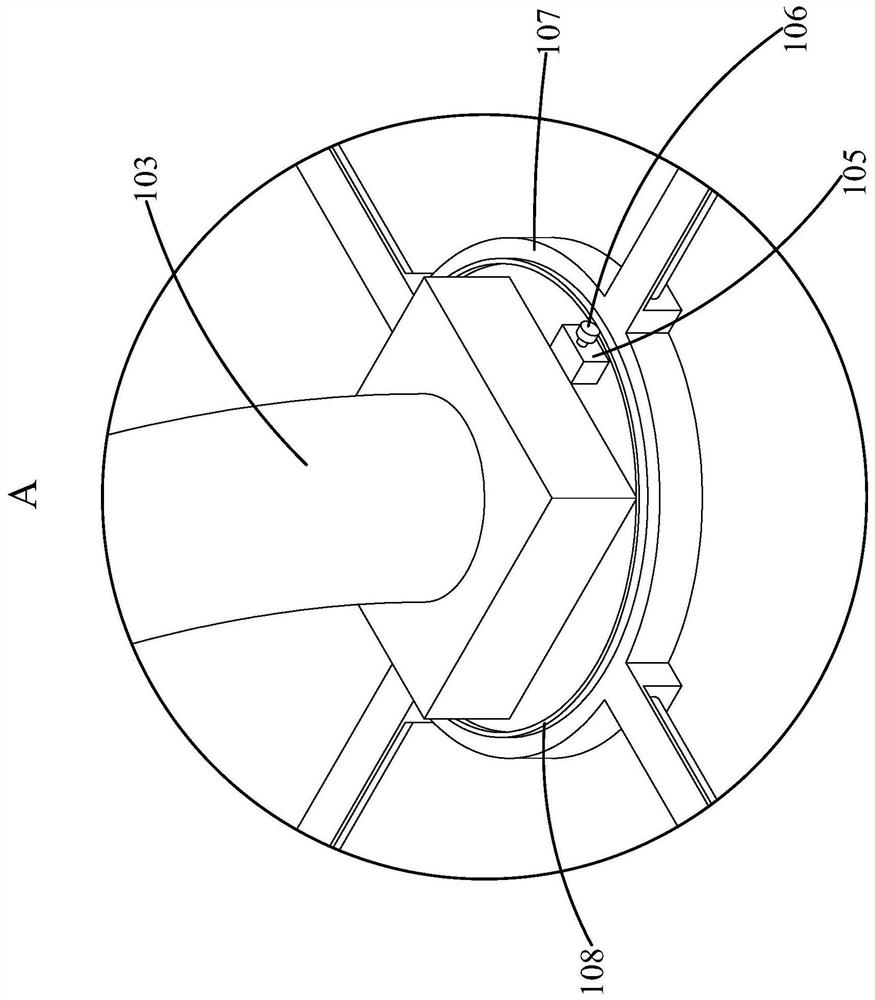

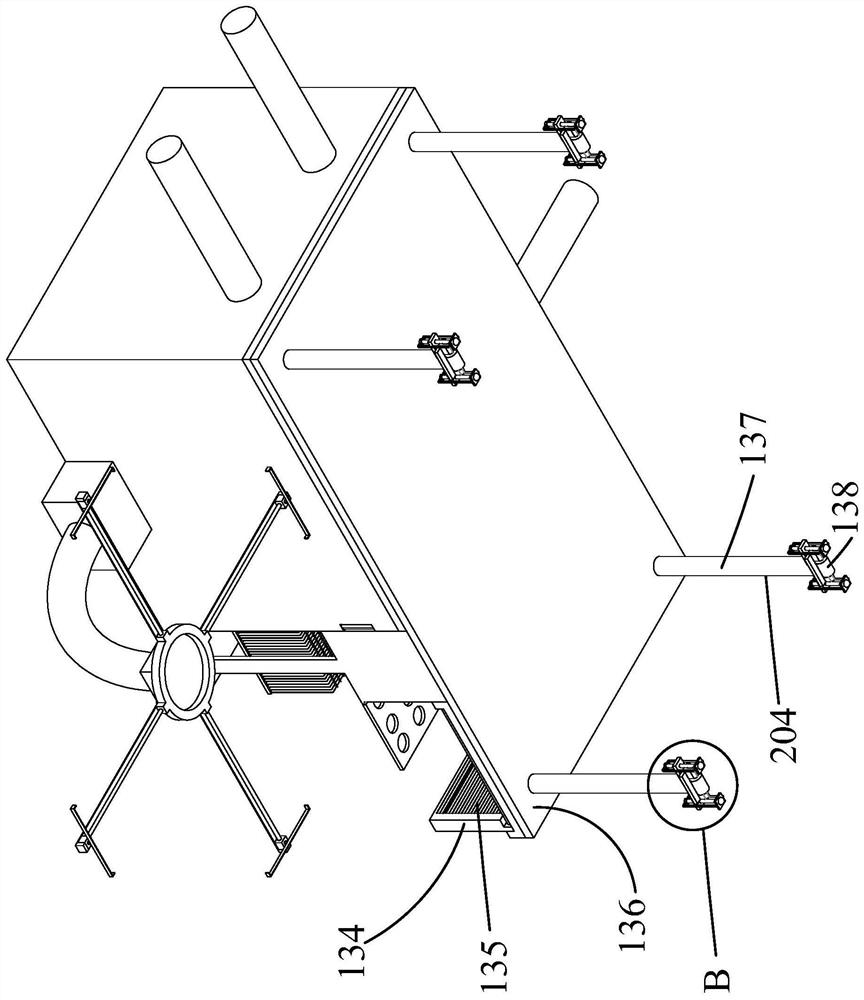

[0028] like Figure 1-Figure 7 As shown, the present invention is described in detail. For the convenience of description, the orientations mentioned below are now stipulated as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship are the same. The sawdust collection and granulation equipment of the present invention includes a chassis 100. A collection mechanism 200 for collecting sawdust is arranged on one side of the chassis 100. A forming machine for forming and bonding sawdust is provided inside the chassis 100. Mechanism 201, a bracket 101 is fixed on one side of the chassis 100, a cutting mechanism 202 for cutting the bonded strip-shaped sawdust blocks is arranged in the bracket 101, and a drying component for drying the shaped particles is arranged on the side of the bracket 101 203, the lower side of the support 101 is provided with a moving mechanism 204 for moving the equipment.

[0029] Beneficially, wherein, the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com