Self-propelled green fodder combine harvester

A combine harvester and green fodder technology, which is applied to harvesters, harvesting platforms, agricultural machinery and implements, etc., can solve the problem of being unable to meet the needs of one-time harvesting of silage fodder, and achieve the promotion of high-efficiency and environmental protection development, small load, and low storage and transportation costs. Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

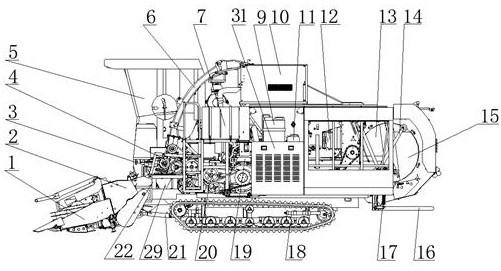

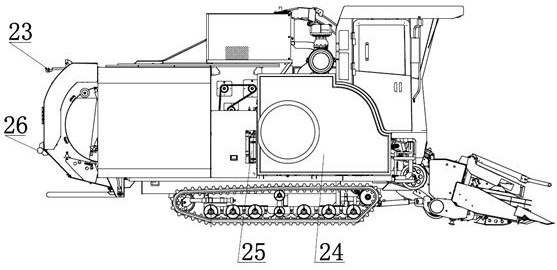

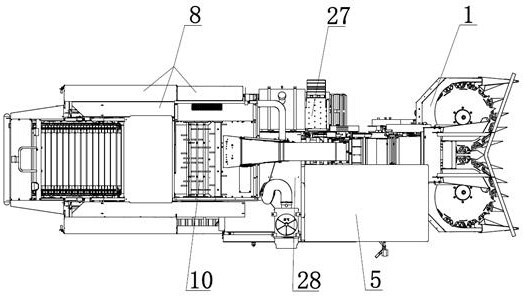

[0027] Such as Figure 1-3Shown, a kind of self-propelled green forage combine harvester comprises header 1, and described header 1 rear is provided with quick dismounting hanger 30, and the frame of quick disassembler hanger 30 and feeding chopping device 2 The main shaft of the feeding and chopping device 2 is installed on the frame protruding from the front of the chassis crawler 18 through the bearing seat of the feeding and chopping device 2. The crawler chassis 18 is the walking and load-bearing device of the whole machine. The various functional components of each are arranged on the crawler chassis 18, and the deflector 29 is installed at the rear of the feeding and chopping device 2. On the one hand, the deflector 29 is used as the installation process plate of the chopping knife, and on the other hand, it is used as the feeding and chopping plate. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com