Heated phase change water-cooled heat dissipation motor

A water-cooled, phase-change technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems that the heat dissipation effect of the heat dissipation port is not obvious, and cannot satisfy the heat dissipation of the motor for a long time, and achieve the effect of improving the secondary heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

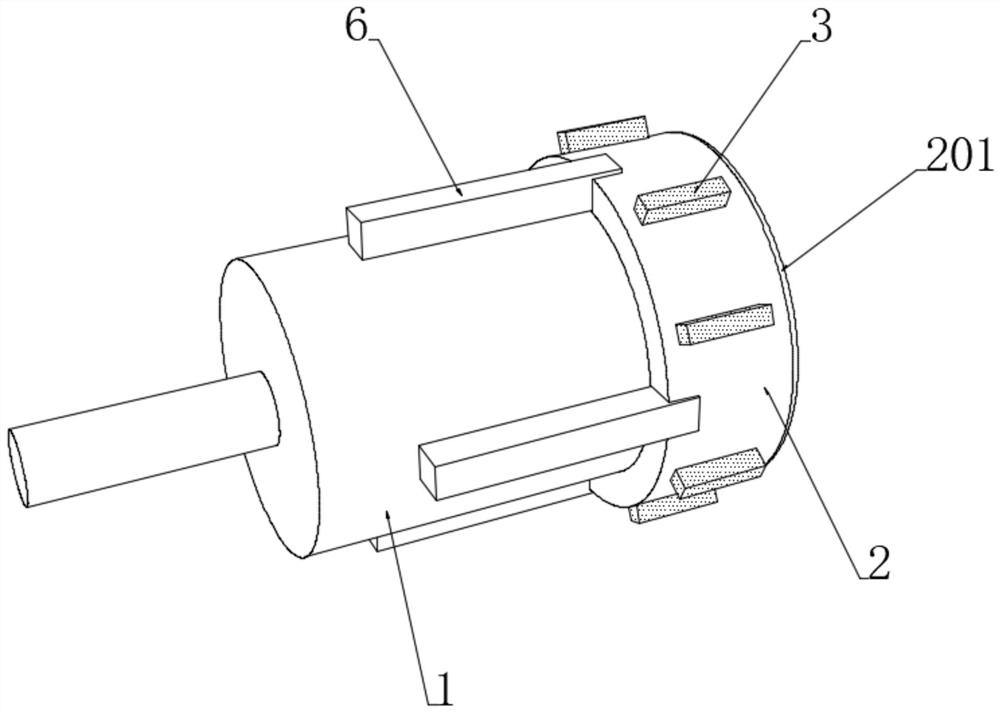

[0040] see Figure 1-4 , a heated phase-change water-cooled heat dissipation motor, including a motor body 1 and a rear end cover 2 connected to the rear end of the motor body 1, a heat dissipation chamber is opened inside the rear end cover 2, and a rear end cover 2 is fixedly connected with a rear The cover plate 201, the side wall of the rear end cover 2 is annularly embedded with multiple groups of cooling plates 3, the inner ends of the plurality of cooling plates 3 are embedded in the inside of the motor body 1, and the end of the cooling plate 3 near the motor body 1 is provided with Embedded in the extension part inside the motor body 1, the cooling plate 3 and its extension form an L-shaped structure. The rear end wall of the motor body 1 is provided with a plurality of heat conduction grooves 101 matching the extension part. When the motor body 1 works After the temperature gradually rises, the motor body 1 utilizes a plurality of heat dissipation plates 3 to dissipa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com