Prefabricated part management method based on BIM-RFID

A technology of prefabricated components and management methods, applied in data processing applications, computer parts, electromagnetic radiation induction, etc., can solve problems such as transmission, inability to retain record traces for a long time, and inability to achieve management.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and examples are only used to explain the present invention and are not intended to limit the scope of the present invention

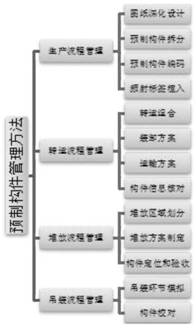

[0029] see figure 1 As shown, the present invention is a BIM-RFID-based prefabricated component management method, including four links of component production, transfer, stacking and hoisting.

[0030] The process management of component production includes: detailed design of design drawings, splitting of prefabricated buildings, coding of prefabricated components and implantation of RFID tags.

[0031] Exemplarily, the detailed design of design drawings means that designers use BIM technology to transform 2D drawings into 3D visualization models for the drawings issued by the design institute. Revit, Bentley, Tekla or Archicad software can be used to build models to form prefabricated Building Production Information Modelin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com