Drying structure and tentering setting machine

A technology of stenter setting machine and drying sheet, which is applied in the direction of drying machine, drying, progressive drying machine, etc., which can solve the problems of large horizontal area occupied, poor stenter effect, and inability to introduce sizing machine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

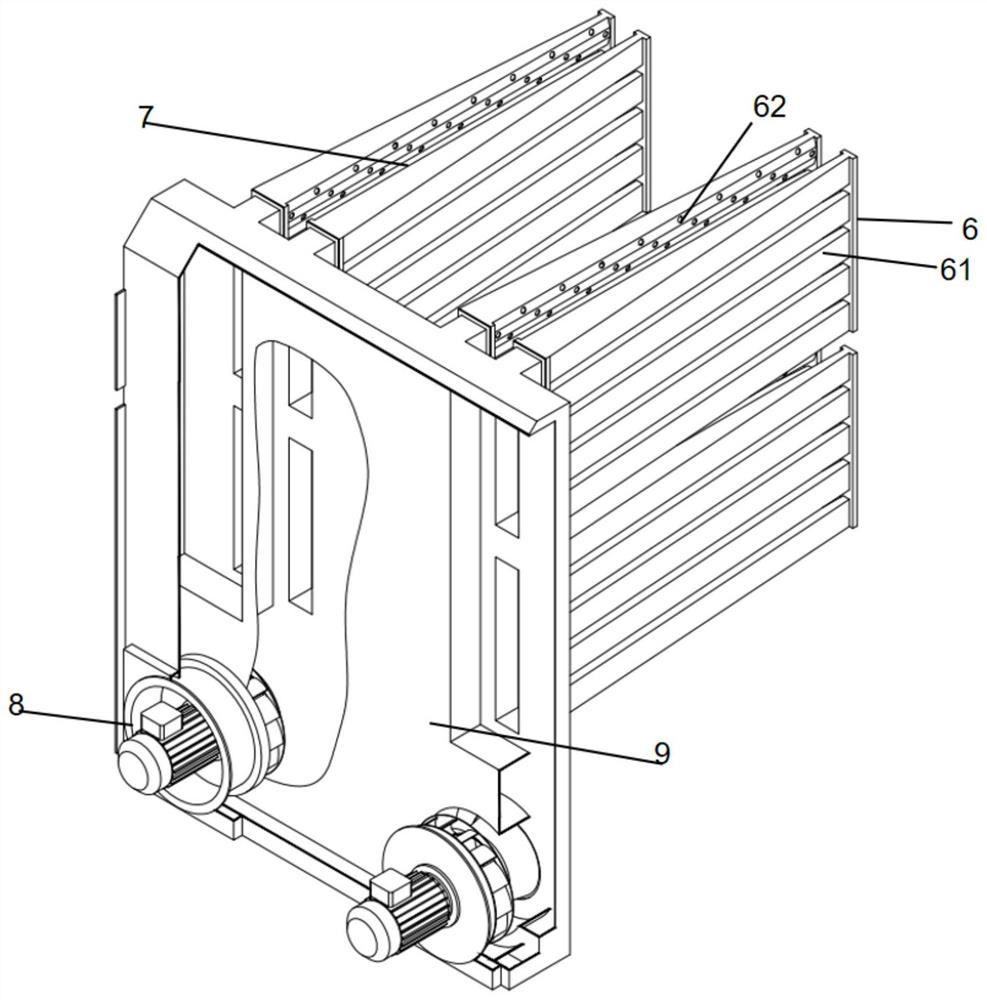

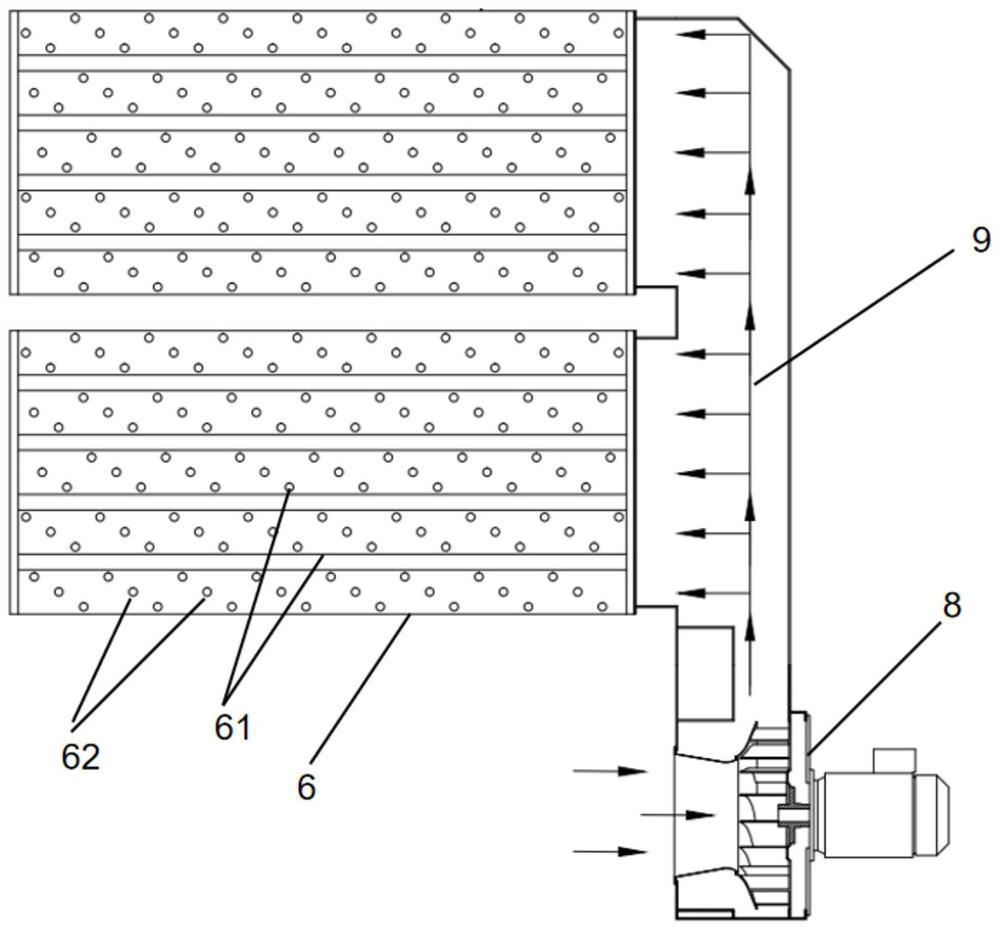

[0038] Such as figure 2 , image 3 As shown, the embodiment of the present application provides a drying structure, including:

[0039] At least two drying sheets 6 arranged at intervals along the first direction, each of which extends along the second direction;

[0040] Two adjacent drying sheets form a drying channel 7, and the drying channel is used for passing the conveying bar 3 for conveying the object to be dried.

[0041] The application provides a drying structure, which forms a drying channel through the drying sheets arranged at intervals, and dries the objects to be dried through the drying channel through the conveying strip (the drying sheets on both sides of the drying channel can be dried drying), so that the space can be effectively used and the drying effect can be improved.

[0042] As a possible implementation, the drying sheets 6 arranged at intervals along the first direction can form a plurality of drying passages, wherein there are at least two dry...

Embodiment 2

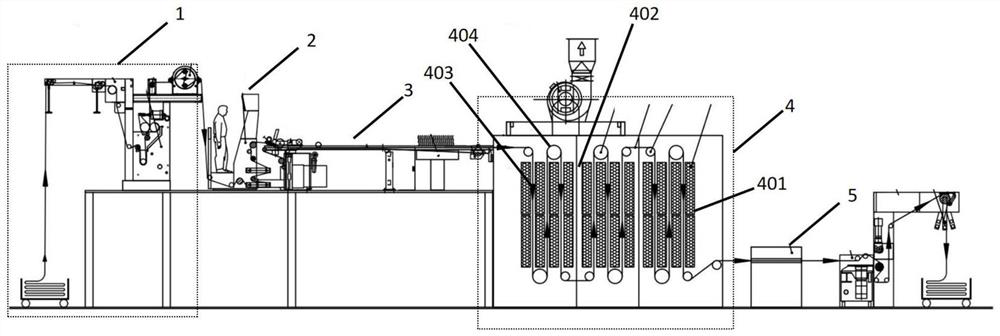

[0057] Such as Figure 3-Figure 6 As shown, the embodiment of the present application provides a tenter setting machine, including the drying structure shown in the first embodiment.

[0058] As a possible implementation, it also includes: a conveying device, the conveying device includes a driving module, and a conveying strip 3 for conveying the objects to be dried, and the conveying strip passes through each of the drying channels 7 in sequence ;

[0059] The driving module is in transmission connection with the conveying bar 3, and is used to drive the conveying bar to move in the drying passage, so that the conveying bar drives the to-be-dried objects to pass through each of the drying channels in sequence. aisle.

[0060] Wherein, the conveying bar 3 can be a conveying belt, a conveying chain, and other methods capable of realizing the functions of the present application.

[0061] A possible implementation of the embodiment of the present application, the drive modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com