Electric heating control method and system based on power line carrier communication

A technology of power line carrier and control method, which is applied in the direction of electric heating system, heating system, heating method, etc., and can solve problems such as obvious, small data, and affecting user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

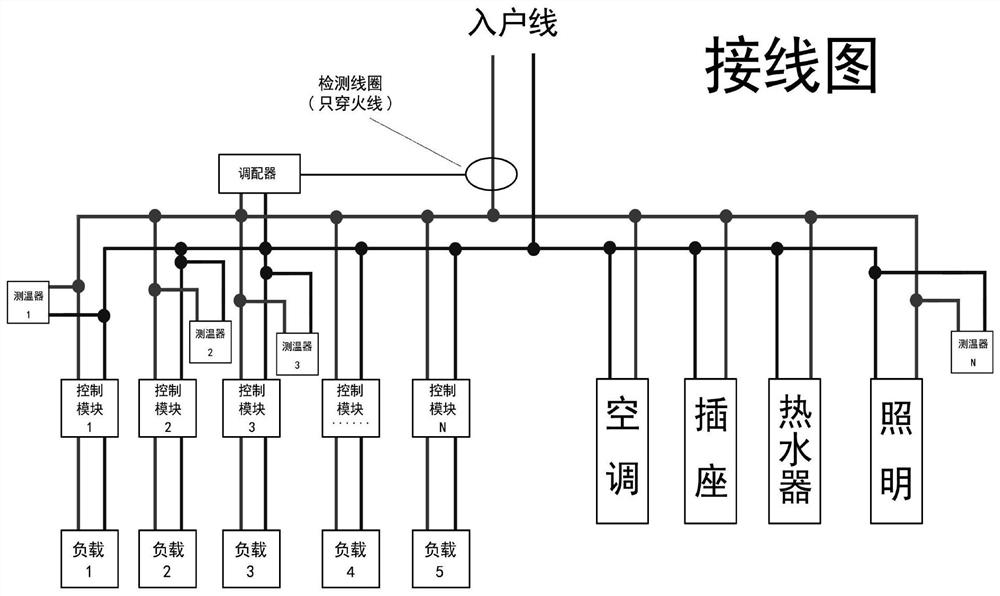

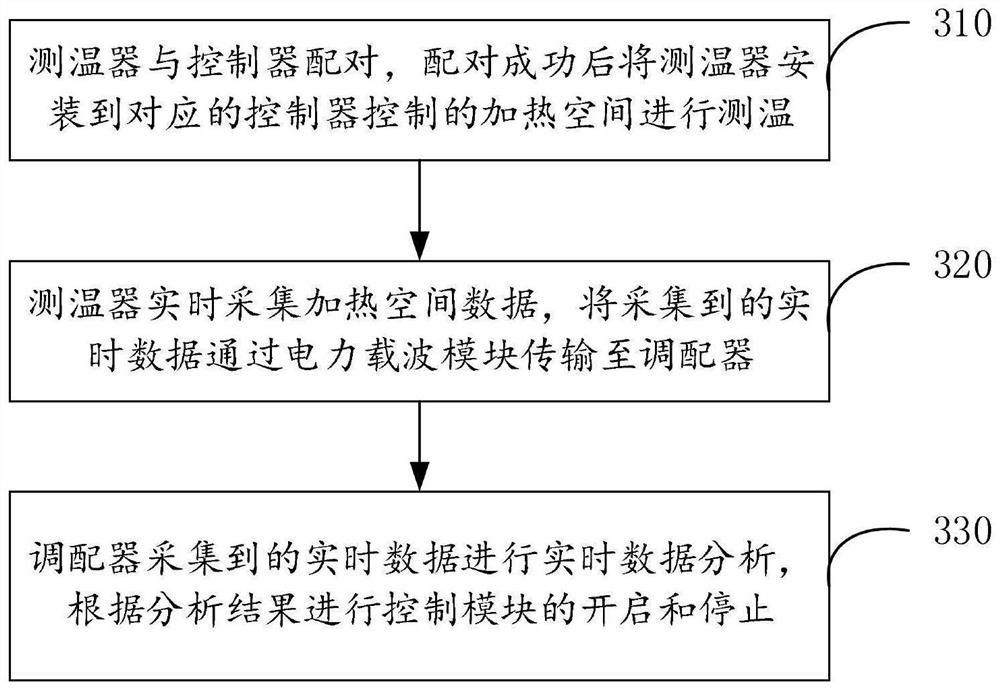

[0024] Embodiment 1 of the present application provides an electric heating control method based on power line carrier communication, which is applied to such as figure 1 In the system composed of the temperature detector, adjuster, controller and load shown; the adjuster is connected to the live wire of the household line, and also connected to the controller and the temperature detector; the temperature detector is connected to the controller and the adjuster; the controller is connected to the adjustment The temperature detector, temperature detector and load; the temperature detector measures the temperature of the heating area, and uploads the temperature to the dispatcher through the power carrier technology, and the dispatcher sends a start-stop instruction to the controller according to the uploaded temperature.

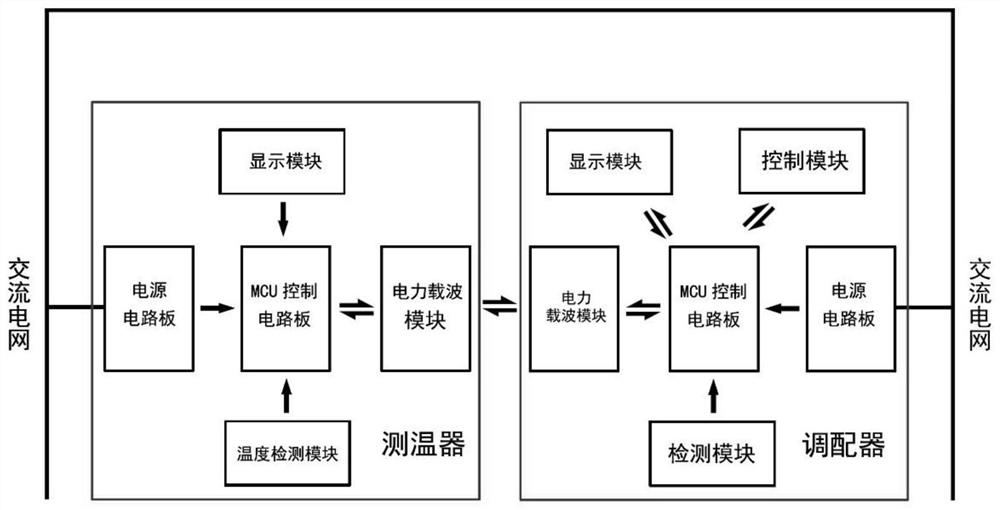

[0025] Among them, such as figure 2 As shown, the temperature detector includes a power supply circuit, a power carrier module, an mcu control board, a temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com