Assembly type wood-bamboo frame-grid wall structure system suitable for village and town residences

A wooden frame and prefabricated technology, applied to walls, building components, building structures, etc., can solve the problems of waste of resources and energy, damage, and difficult recycling of building materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

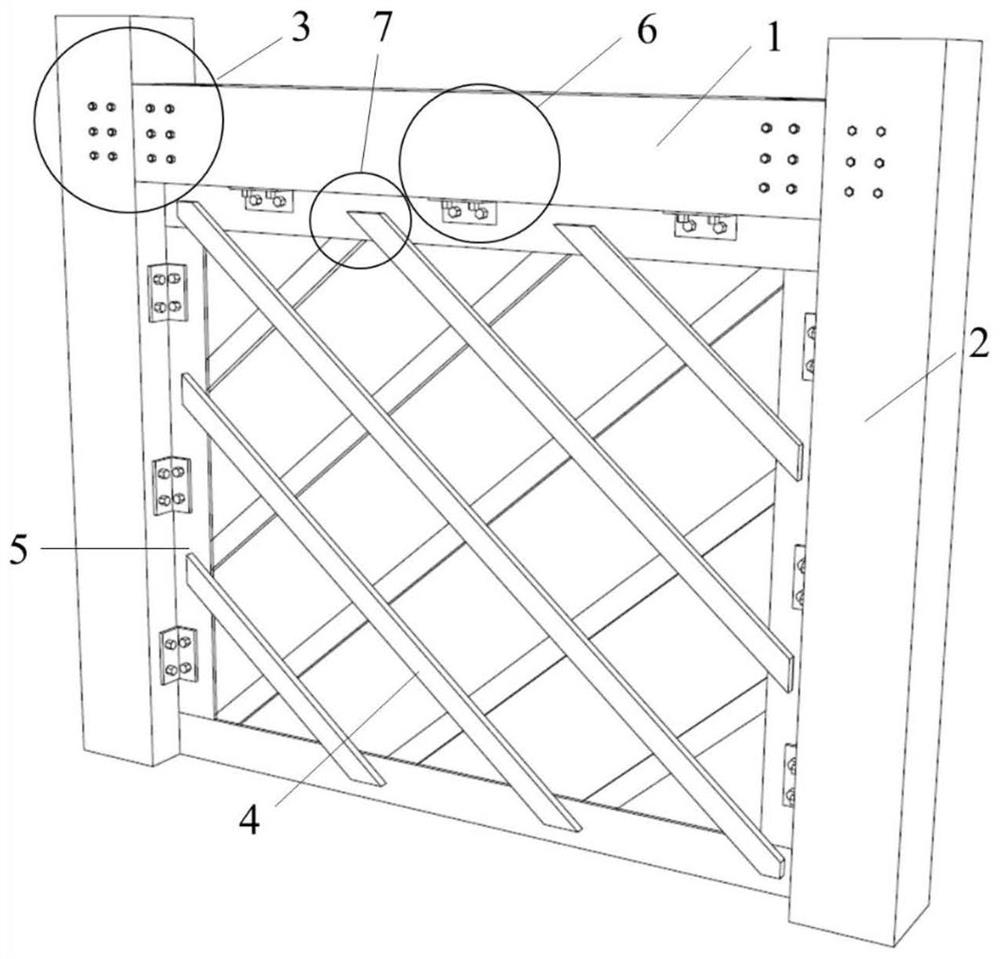

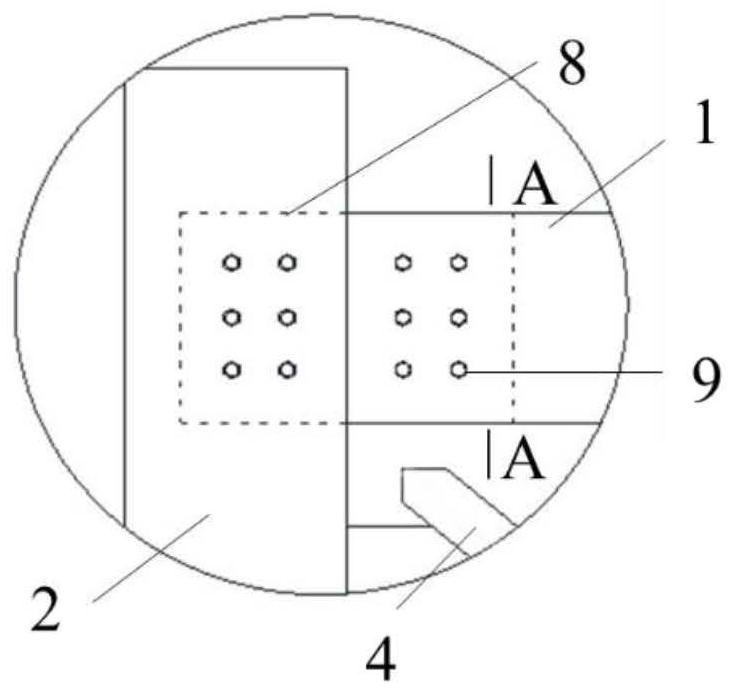

[0032] see Figure 1 to Figure 11, a low-story prefabricated wood-bamboo frame-grid wall structure suitable for rural residences, including an external wooden frame composed of wooden beams 1 and wooden columns 2, and an internal wooden grid composed of wooden grid members 4 The shear wall or the internal bamboo grid shear wall composed of bamboo grid components 13, that is, the wood and bamboo frame-grid wall structure can be specifically divided into wood frame-wood grid wall structure and wood frame-bamboo grid wall structure 2 forms.

[0033] The wood frame-wood grid shear wall structure consists of an external wood frame and an internal wood grid shear wall. The external wooden frame is formed by connecting wooden beams 1 and wooden co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com