Ultra-low water level dynamic compaction system and method

A water level, ultra-low technology, applied in soil protection, construction, infrastructure engineering, etc., can solve the problems of large settlement, low building strength, rapid rise, etc., and achieve the effect of small settlement and high building strength after construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

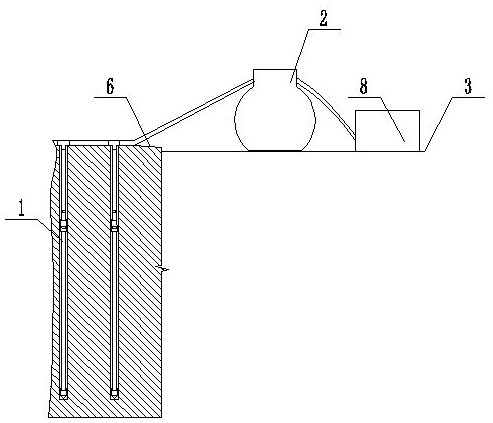

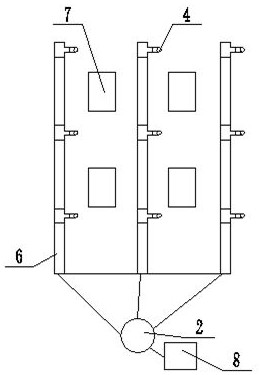

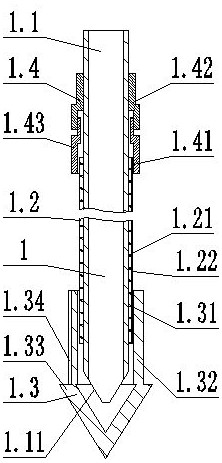

[0033] Embodiment 1: as figure 1 , 2 , 3, 4, 5, and 6, a kind of ultra-low water level dynamic compaction system includes an ultra-low water level dewatering booster pipe 1, a gas-liquid separation tank 2, a vacuum host 8, and several Holes 4, several rows of holes 4, ultra-low water level dewatering booster pipe 1 is inserted in the hole 4, the top of ultra-low water level dewatering booster tube 1 is connected to gas-liquid separation tank 2 through pipeline 6, gas-liquid separation tank 2 It is connected with the vacuum main engine 8, and several dynamic compactors 7 are arranged on the ground 3, and the dynamic compactors 7 are located between two adjacent rows of holes 4; the ultra-low water level dewatering booster pipe 1 includes a core tube 1.1, and the outer wall of the core tube 1.1 A filter tube 1.2 is provided, and the filter tube 1.2 includes a skeleton 1.21 and a filter mesh cloth 1.22 covered outside the skeleton 1.21, the skeleton 1.21 is a steel wire spiral s...

Embodiment 2

[0034] Embodiment 2: as Figure 7 As shown, a kind of ultra-low water level dynamic compaction method, inserts some ultra-low water level dewatering booster pipes 1 in the hole 4 of reinforced soil; Liquid separation tank 2, open the gas-liquid separation tank 2 and the vacuum host 8 after the connection, the water inside the reinforced land will be sucked into the gas-liquid separation tank 2, and a shaft 5 will be opened on the ground of the reinforced soil body, and the gas-liquid separation tank 2 will be placed in In the shaft 5; when the groundwater liquid level of the reinforced land falls to the water level requirement, the reinforced soil body is rammed with a dynamic tamping machine 7, several rows of ultra-low water level dewatering booster pipes 1 are inserted and arranged in parallel, and the pipeline 6 is horizontal The pipe network is arranged, the ultra-low water level dewatering booster pipe 1 is connected to the horizontal pipe network by a tee, the gas-liqui...

Embodiment 3

[0035] Embodiment 3: as Figure 8 As shown, with reference to Example 2, the gas-liquid separation tank 2 and the vacuum host 8 can be replaced by a tumbler-type water collecting device 9 for vacuum preloading with the patent number CN104294812B.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com