Double-bleaching with sodium chlorite and double-oxygen-bleaching process for linen

A linen yarn and process technology, used in textiles and papermaking, can solve the problems of large damage to fiber strength and affect the spinnability of linen yarn, and achieve the effect of maintaining yarn quality, keeping skin fresh, and increasing spinnability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

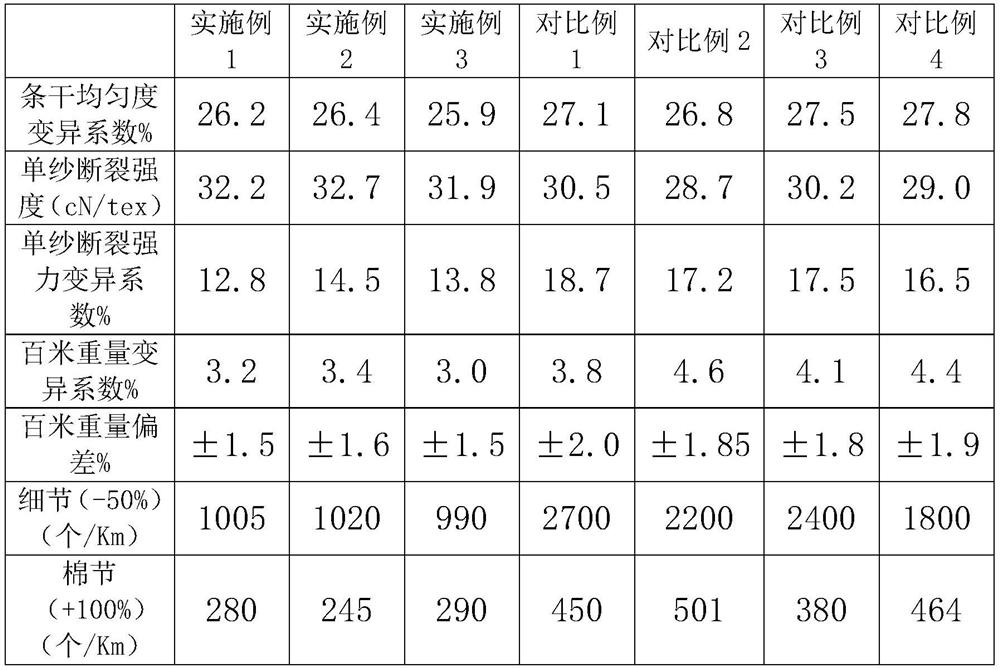

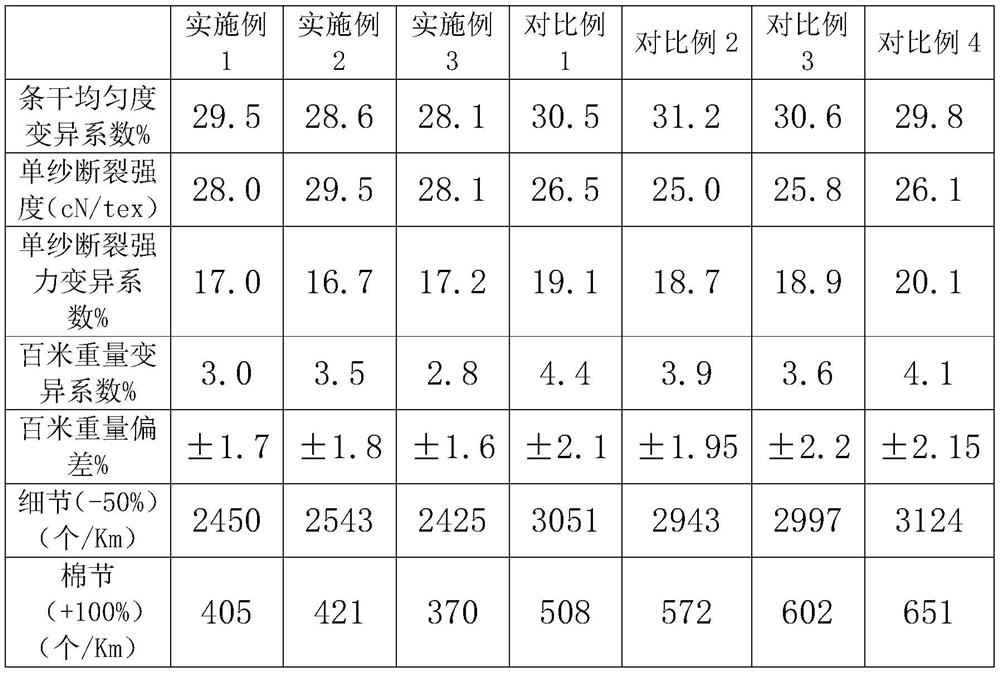

Examples

Embodiment 1

[0026] A double sub-bleaching and double-oxygen bleaching process for flax yarn, specifically comprising the following steps:

[0027] Step A pretreatment process: add sulfuric acid: 1.5g / L, scouring agent TP: 0.8g / L into deionized water, stir evenly, adjust the temperature to 28°C, and process for 35 minutes; no liquid drainage;

[0028] Step B sub-bleaching process 1: continue to add NaClO 2 、NaNO 3 and stabilizer, stir evenly, adjust the temperature to 48°C, and process for 35 minutes; drain;

[0029] Step C sub-bleaching process 2: sulfuric acid, scouring agent, NaClO 2 、NaNO 3 , stabilizer and deionized water are stirred evenly, the temperature is adjusted to 50°C, and the processing time is 35 minutes; draining; washing with water for 15 minutes; overflowing for 18 minutes;

[0030] Step D oxygen bleaching process 1: the penetrant, scouring agent, NaOH, Na 2 CO 3 , stabilizer, Na 2 SiO 3 、H 2 o 2 Stir with deionized water evenly, adjust the temperature to 90°C±...

Embodiment 2

[0037] A double sub-bleaching and double-oxygen bleaching process for flax yarn, specifically comprising the following steps:

[0038] Step A pretreatment process: add sulfuric acid: 1.8g / L, scouring agent TP: 0.4g / L into deionized water, stir evenly, adjust the temperature to 30°C, and process for 20 minutes; do not drain;

[0039] Step B sub-bleaching process 1: continue to add NaClO 2 、NaNO 3 and stabilizer, stir evenly, adjust the temperature to 55°C, and process for 20 minutes; drain;

[0040] Step C sub-bleaching process 2: sulfuric acid, scouring agent, NaClO 2、NaNO 3 , stabilizer and deionized water are stirred evenly, the temperature is adjusted to 55°C, and the treatment time is 20 minutes; draining; washing with water for 20 minutes; overflowing for 15 minutes;

[0041] Step D oxygen bleaching process 1: the penetrant, scouring agent, NaOH, Na 2 CO 3 , stabilizer, Na 2 SiO 3 、H 2 o 2 Stir with deionized water evenly, adjust the temperature to 90°C±1.5°C, a...

Embodiment 3

[0048] A double sub-bleaching and double-oxygen bleaching process for flax yarn, specifically comprising the following steps:

[0049] Step A pretreatment process: add sulfuric acid: 1g / L, scouring agent TP: 1g / L into deionized water, stir evenly, adjust the temperature to 25°C, and process for 40 minutes; no liquid is drained;

[0050] Step B sub-bleaching process 1: continue to add NaClO 2 、NaNO 3 and stabilizer, stir evenly, adjust the temperature to 45°C, and process for 50 minutes; drain;

[0051] Step C sub-bleaching process 2: sulfuric acid, scouring agent, NaClO 2 、NaNO 3 , stabilizer and deionized water are stirred evenly, the temperature is adjusted to 45°C, and the treatment time is 50 minutes; drain; wash with water for 10 minutes; overflow for 20 minutes;

[0052] Step D oxygen bleaching process 1: the penetrant, scouring agent, NaOH, Na 2 CO 3 , stabilizer, Na 2 SiO 3 、H 2 o 2 Stir with deionized water evenly, adjust the temperature to 90°C±1.5°C, and p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com