Bicomponent Fiber Spinning Package

A technology of bi-component fibers and spinning components, which is applied in fiber processing, spinning solution defoaming, textile and papermaking, etc., can solve the problems of polylactic acid fiber strength that cannot meet the requirements of the industry, degradation of low-melting point bodies, etc. To achieve the effect of excellent voltage stabilization and filtering, reducing the probability of mutual influence and ideal fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to understand the technical essence and beneficial effects of the present invention more clearly, the applicant will describe in detail the following examples, but the descriptions of the examples are not intended to limit the solutions of the present invention. Equivalent transformations that are only formal but not substantive should be regarded as the scope of the technical solution of the present invention.

[0024] In the following descriptions, all concepts related to the directionality or orientation of up, down, left, right, front and rear are taken as examples in the illustrated position state, and thus cannot be interpreted as the technology provided by the present invention. Program specific restrictions.

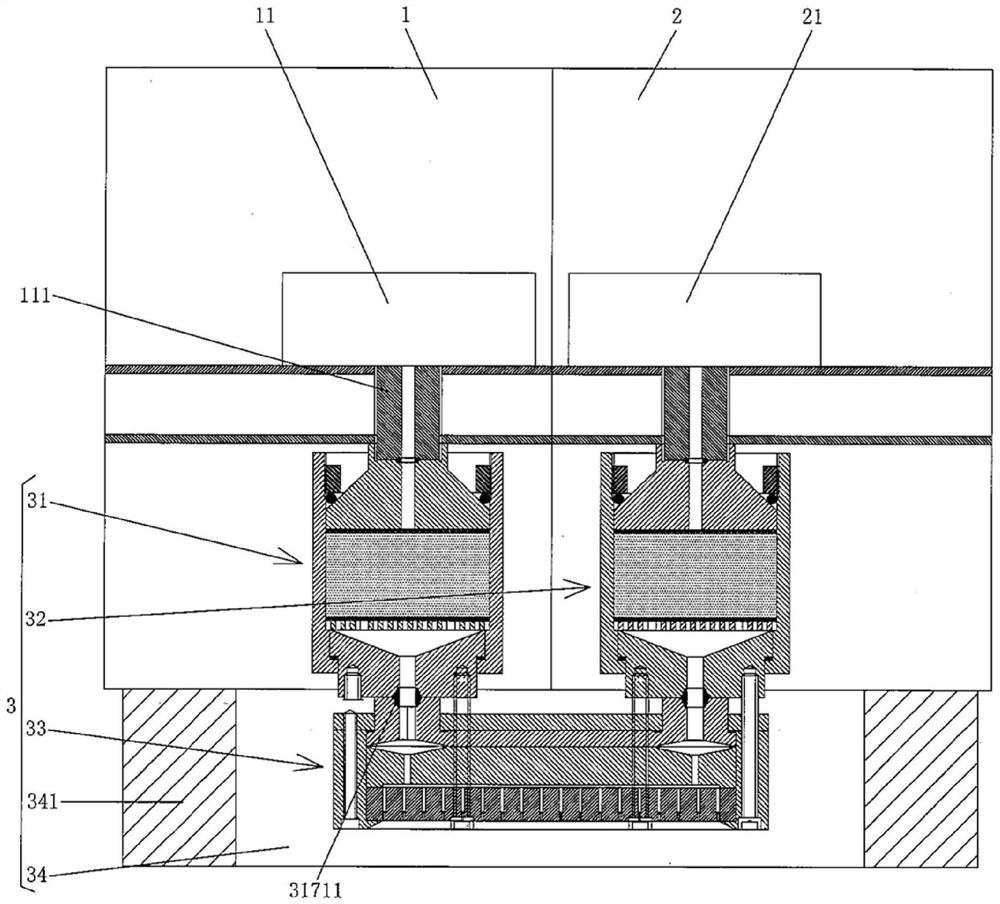

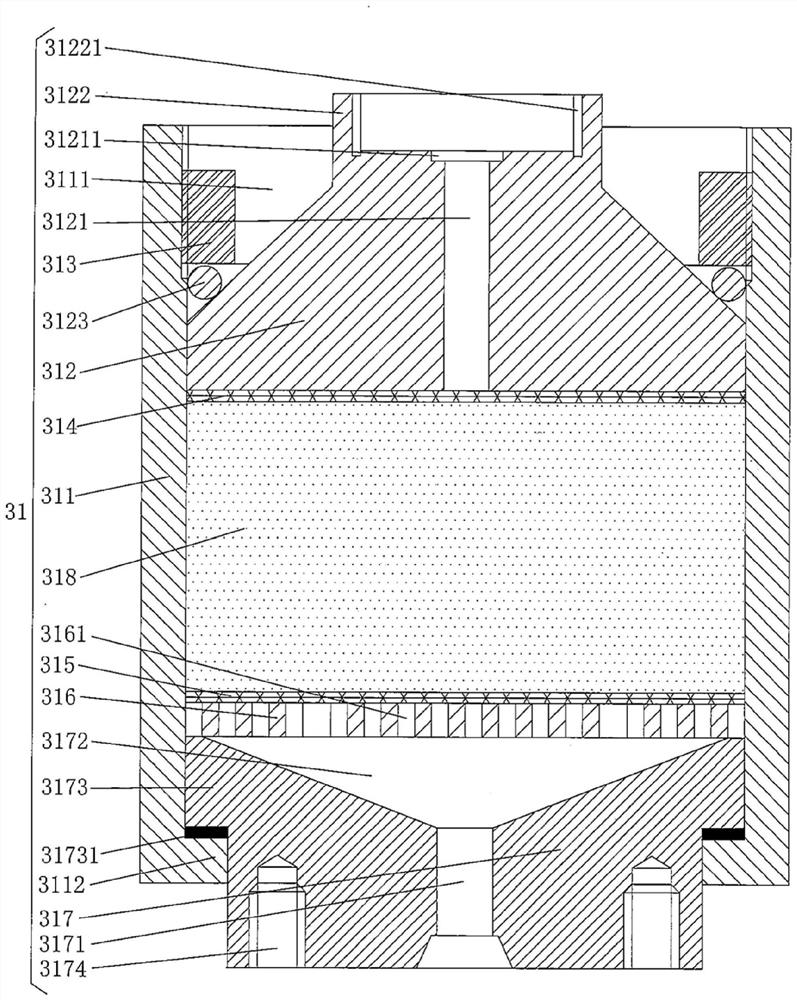

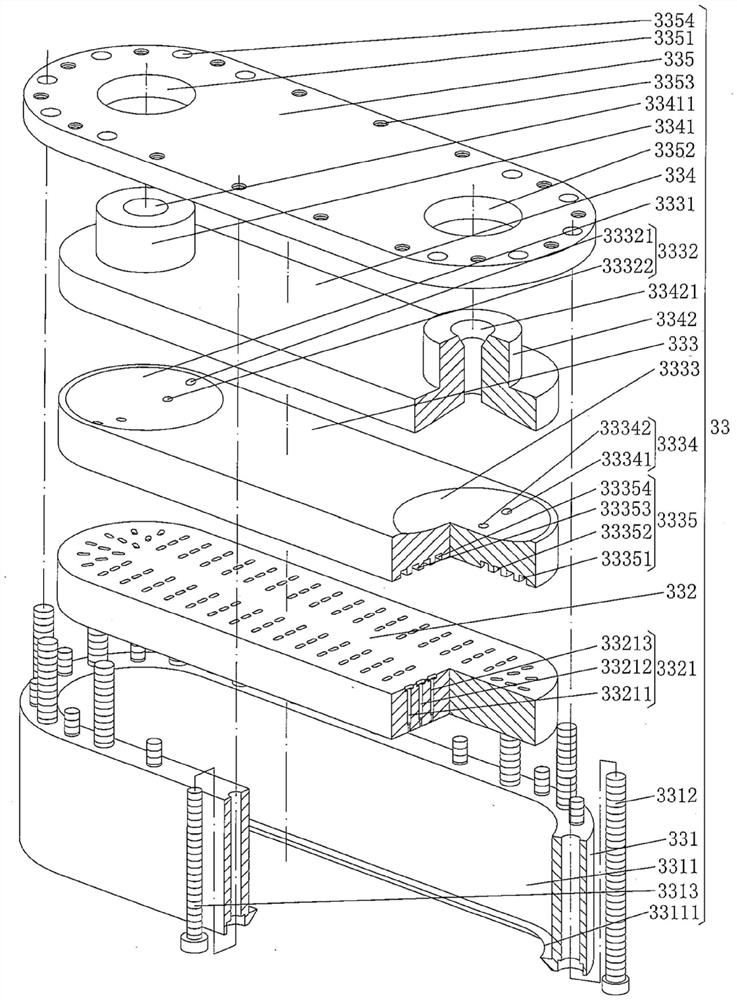

[0025] See figure 1 , showing the first spinning box I1, the second spinning box II2 and the spinning mechanism 3, in the first spinning box I1 is provided with the melt extruded by the first screw extruder and by the first The first metering p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com