Expandable graphite modified SMC material

A technology of expanding graphite and modification, which is applied in the field of SMC materials modified by expandable graphite, can solve the problems of poor compatibility between flame retardants and organic materials, decreased mechanical properties, and decreased material toughness, so as to improve mechanical properties and reduce Dosage, the effect of promoting carbonization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

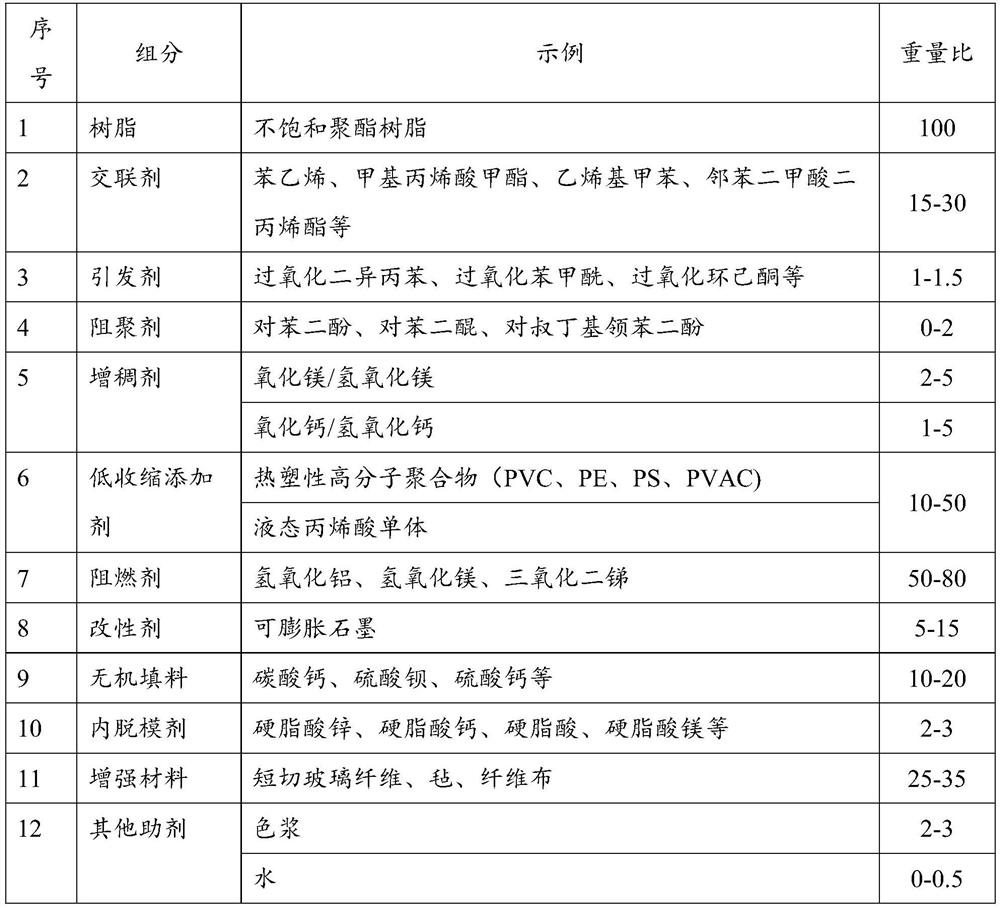

Method used

Image

Examples

Embodiment Construction

[0011] The technical solution of the present invention is clearly and completely described below. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention.

[0012] The present invention uses expandable graphite to replace a part of inorganic flame retardants (aluminum hydroxide, etc.), reduces the amount of inorganic fillers and other components in the total system, and improves the flame retardancy of SMC materials through blending modification, thereby indirectly improving the use of the SMC. The mechanical strength of a product formed from a material.

[0013] At the same time, because expandable graphite has the ability to resist damage at high temperatures and has a high expansion rate, and is non-toxic and non-polluting, it can be used alone or mixed with other flame retardants to achieve the ideal flame retardant effect. ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com