A weather-resistant oil-water mixed gel platform and its preparation method and application

A technology of oil-water mixing and weather resistance, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrolytes, etc., can solve problems such as unsuitable storage, long-term use, dehydration, etc., and achieve improved mechanical properties, mild conditions, and good compatibility sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

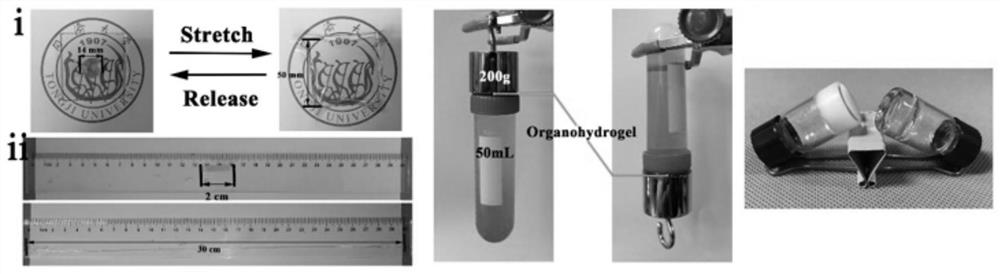

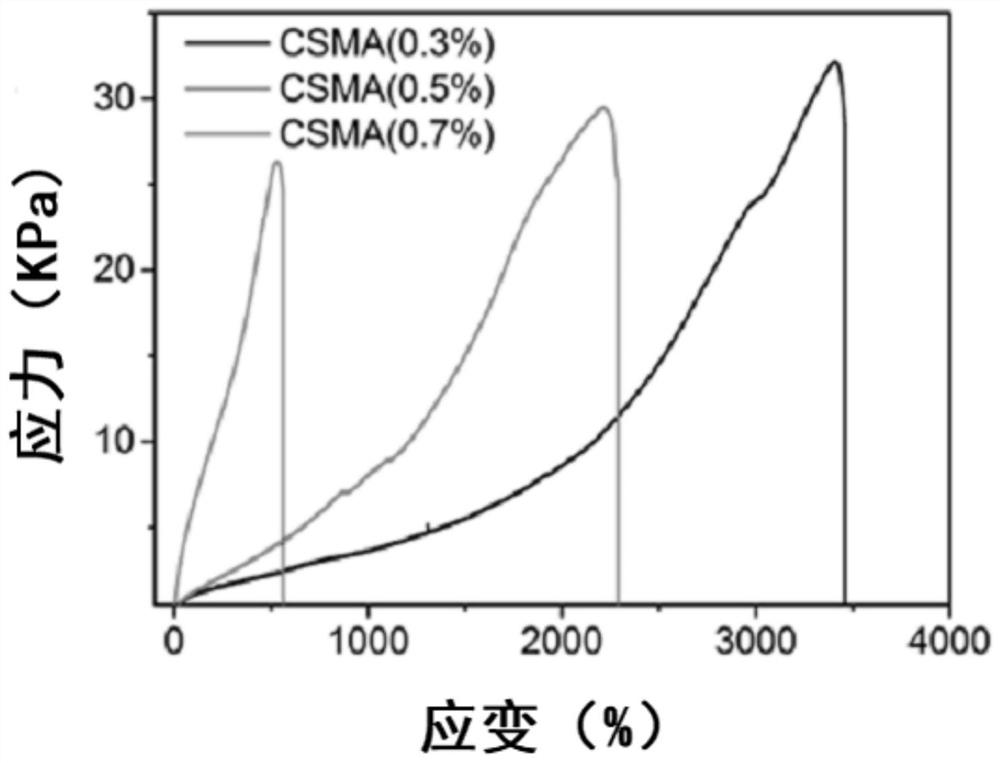

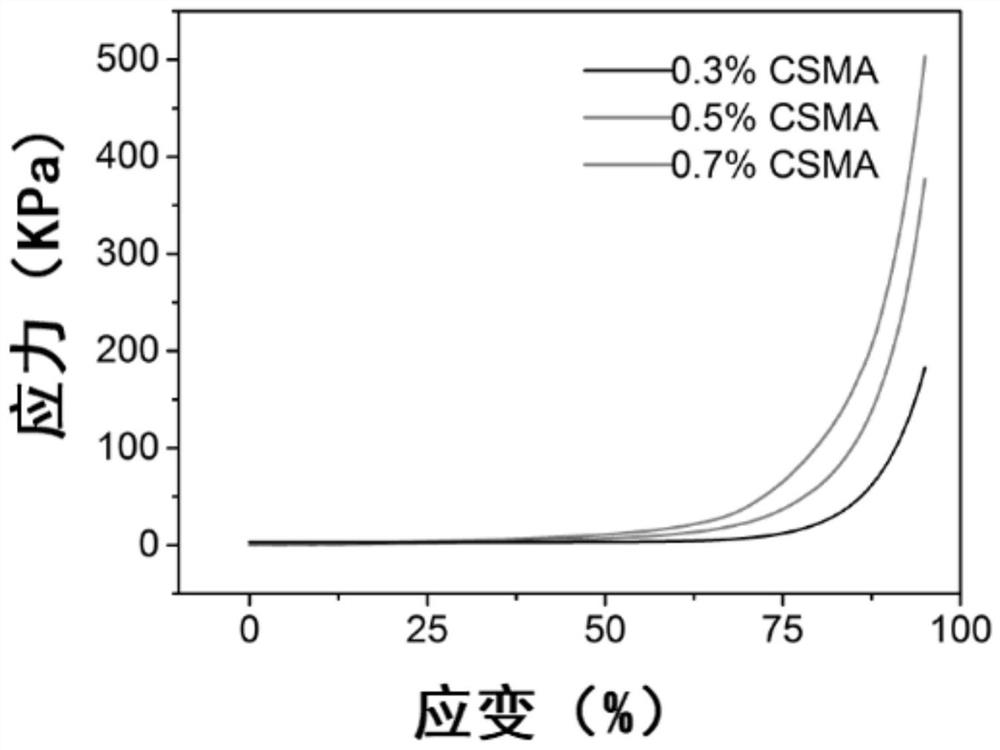

[0053] Add 200 μL of acrylic acid (AA) and 5 mg of propenylated chondroitin sulfate (CSMA) into 500 μL of ethylene glycol / water mixed solvent (50% v / v), and stir until the solution is clear. 108 μL of concentrated sulfuric acid was diluted to 500 μL with an ethylene glycol / water mixed solvent (50% v / v), and added to the solution prepared above. Finally, 5 μL of 2,2-diethoxyacetophenone was added and irradiated under ultraviolet light for 30 minutes to obtain an oil-water mixed gel platform. The oil-water hybrid gel can be uniaxially stretched to 1500%, and biaxially stretched to 1200% strain; it can withstand 95% of its own compressive deformation; the peel strength with carbon cloth is 546J m -2 ;It can withstand the low temperature of -40°C and the high temperature of 80°C, the ion conductivity at 80°C is 26.6mS / cm, and the ion conductivity at -40°C is 4.5mS / cm; used in supercapacitors to realize energy storage.

[0054] Such as figure 1 As shown, the oil-water hybrid gel ...

Embodiment 2

[0074] Add 200 μL of acrylic acid (AA) and 3 mg of propenylated chondroitin sulfate (CSMA) into 500 μL of ethylene glycol / water mixed solvent (50% v / v), and stir until the solution is clear. 108 μL of concentrated sulfuric acid was diluted to 500 μL with an ethylene glycol / water mixed solvent (50% v / v), and added to the solution prepared above. Finally, 5 μL of 2,2-diethoxyacetophenone was added and irradiated under ultraviolet light for 30 minutes to obtain an oil-water mixed gel platform.

Embodiment 3

[0076] Add 200 μL of acrylic acid (AA) and 7 mg of propenylated chondroitin sulfate (CSMA) into 500 μL of ethylene glycol / water mixed solvent (50% v / v), and stir until the solution is clear. 108 μL of concentrated sulfuric acid was diluted to 500 μL with an ethylene glycol / water mixed solvent (50% v / v), and added to the solution prepared above. Finally, 5 μL of 2,2-diethoxyacetophenone was added and irradiated under ultraviolet light for 30 minutes to obtain an oil-water mixed gel platform.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com