Soil remediation fertilizer and preparation method thereof

A soil repair and fertilizer technology, applied in the direction of organic fertilizer, inorganic fertilizer, ammonium salt fertilizer, etc., can solve the problems of endangering human health and life safety, crop production quality, decline, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

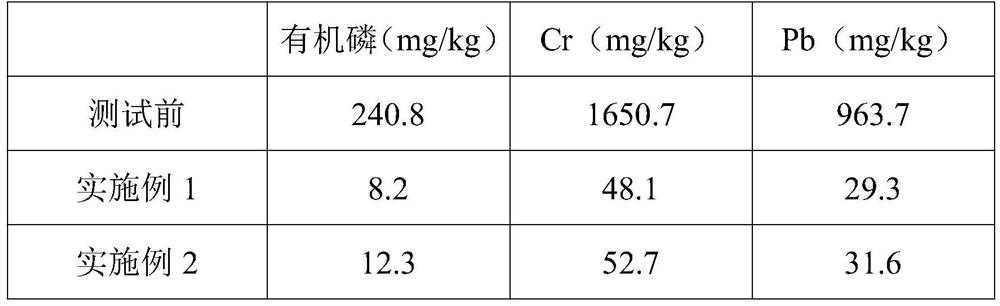

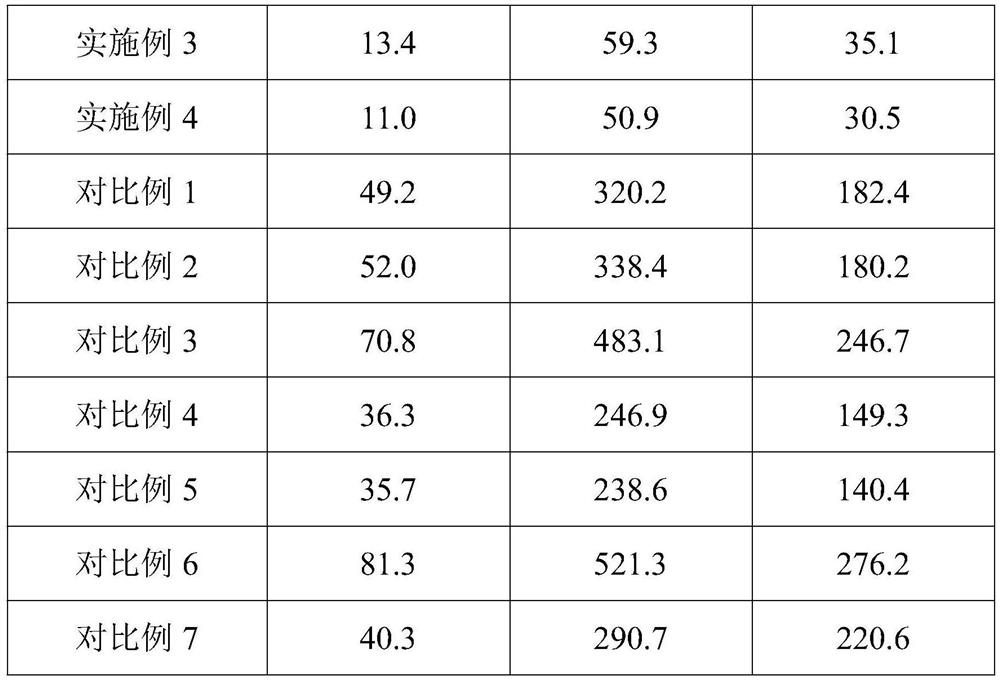

Examples

Embodiment 1

[0035] A kind of soil restoration fertilizer, described soil restoration fertilizer is made of following raw materials by weight: 30.9 parts of modified phosphogypsum, 21 parts of urea, 15 parts of modified porous ceramsite, 10 parts of diatomite, 6 parts of plant ash, 5 parts of Ammonium dihydrogen phosphate, 3.5 parts of fly ash, 3 parts of titanium dioxide, 2 parts of calcium polysulfide, 1.5 parts of ammonium chloride, 1.2 parts of chitosan, 0.5 parts of sodium carboxymethylcellulose, and 0.4 parts of fulvic acid.

[0036] The preparation method of described modified phosphogypsum is:

[0037] S1. Calcining phosphogypsum at 175°C for 3 hours to obtain calcined phosphogypsum; calcining medical stone powder at 280°C for 2 hours to obtain calcined medical stone powder;

[0038] S2. Mix the calcined phosphogypsum and the calcined medical stone powder evenly according to the weight ratio of 1:0.4 to obtain a composite powder;

[0039] S3. Calcining the composite powder at 550°...

Embodiment 2

[0051] A soil repair fertilizer, said soil repair fertilizer is made of the following raw materials in parts by weight: 22 parts of modified phosphogypsum, 25 parts of urea, 12 parts of modified porous ceramsite, 6 parts of diatomite, 4 parts of plant ash, 3 parts of Ammonium dihydrogen phosphate, 3 parts of fly ash, 2.5 parts of titanium dioxide, 1.8 parts of calcium polysulfide, 1 part of ammonium chloride, 1 part of chitosan, 0.2 parts of sodium carboxymethylcellulose, 0.1 part of fulvic acid.

[0052] The preparation method of described modified phosphogypsum is:

[0053] S1. Calcining phosphogypsum at 175°C for 3 hours to obtain calcined phosphogypsum; calcining medical stone powder at 280°C for 2 hours to obtain calcined medical stone powder;

[0054] S2. Mix the calcined phosphogypsum and the calcined medical stone powder evenly according to the weight ratio of 1:0.4 to obtain a composite powder;

[0055] S3. Calcining the composite powder at 550° C. for 2 hours to obt...

Embodiment 3

[0067] A soil repair fertilizer, said soil repair fertilizer is made of the following raw materials in parts by weight: 28 parts of modified phosphogypsum, 24 parts of urea, 14 parts of modified porous ceramsite, 11 parts of diatomaceous earth, 7 parts of plant ash, 7 parts of Ammonium dihydrogen phosphate, 5 parts of fly ash, 3.5 parts of titanium dioxide, 3 parts of calcium polysulfide, 2 parts of ammonium chloride, 1.5 parts of chitosan, 0.6 parts of sodium carboxymethyl cellulose, and 0.5 parts of fulvic acid.

[0068] The preparation method of described modified phosphogypsum is:

[0069] S1. Calcining phosphogypsum at 175°C for 3 hours to obtain calcined phosphogypsum; calcining medical stone powder at 280°C for 2 hours to obtain calcined medical stone powder;

[0070] S2. Mix the calcined phosphogypsum and the calcined medical stone powder evenly according to the weight ratio of 1:0.4 to obtain a composite powder;

[0071] S3. Calcining the composite powder at 550° C. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com