Advanced treatment and recycling device for ship tail gas desulfurization washing wastewater

A ship tail gas and advanced treatment technology, applied in water/sewage treatment, special compound water treatment, light water/sewage treatment, etc., can solve problems such as low efficiency, incomplete removal of pollutants, large sludge production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

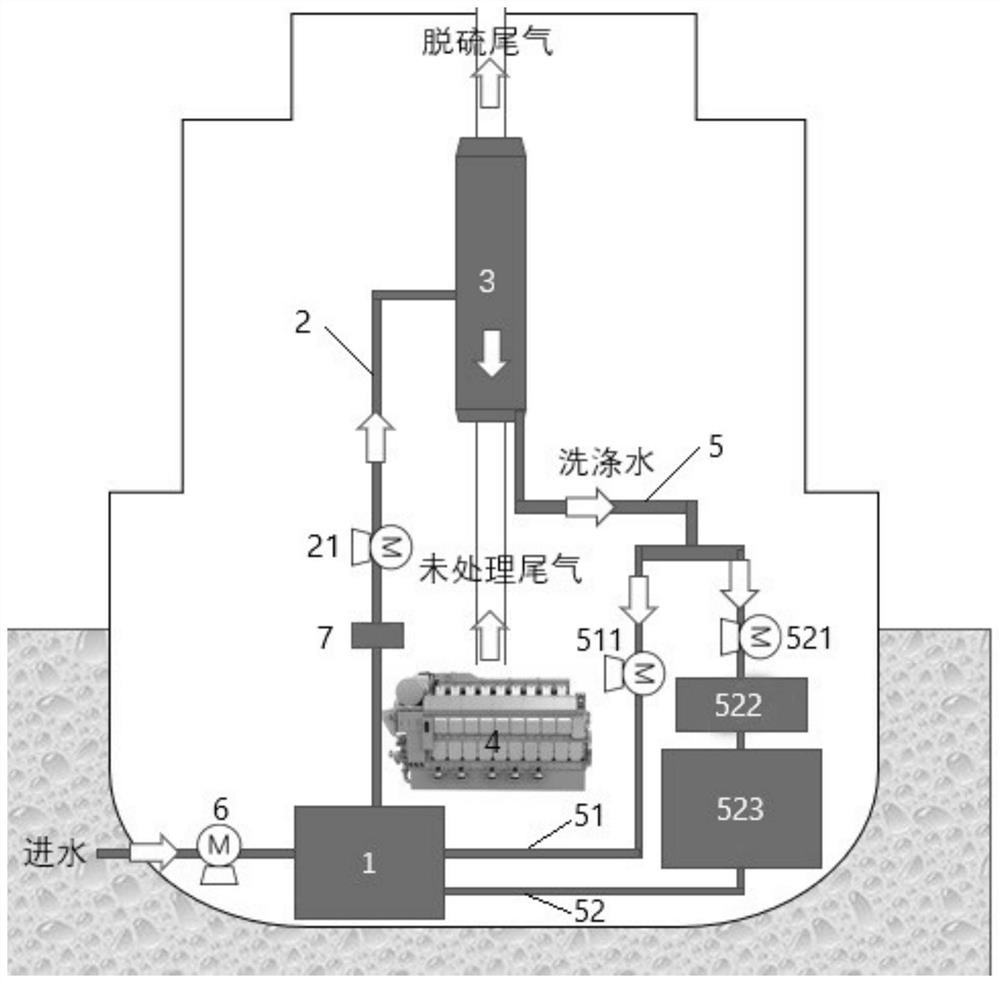

[0050] The marine engine 4 of the applicable ship is a WARTSILA-SULZER RT fiex50 low-speed diesel engine with a total smoke emission of 4×10 4 N M 3 / h, the flow rate of lift pump 21 is 0-80m 3 / h, the initial temperature of flue gas is 300℃, SO 2 The initial concentration is about 500mg / Nm 3 . The generated flue gas is desulfurized and washed using the magnesium-based seawater method, and the washing water contains 1% concentration of Mg(OH) 2 , the closed-circuit marine tail gas desulfurization washing system was started for 2 hours, and the tail gas desulfurization washing water in the initial washing water storage tank 1 was 2.7m 3 . The flow rate of the second backflow pump 521 is 7.5L / min, and the volume of the reaction chamber of the waste water processor 523 is 0.2m 3 , 50 UV lamps with a power of 54w and an emission band of 254nm are arranged at equal intervals in the reactor, the network-like nitrogen-doped titanium dioxide supported catalyst is evenly arranged...

Embodiment 2

[0052] The applicable ship engine is a MAN 6S35MC low-speed diesel engine. When the engine load is 50%, the total smoke emission of the ship engine 4 is 28000kg / h, and the fuel used is high-sulfur 3.5% marine fuel oil. Under the condition that the efficiency is above 99%, it needs to consume 50L of sodium hydroxide solution with a mass fraction of 20% per hour, that is, 50L of desulfurization tail gas washing water loses the effect of desulfurization. The total amount of desulfurization tail gas washing water in the initial washing water storage tank 1 is 0.5m 3 . The flow rate of the second reflux pump 521 is 5L / min, and the volume of the reaction chamber of the waste water processor 523 is 0.5m 3 , 100 UV lamps with a power of 38w and emission bands of 254nm and 185nm are arranged at equal intervals in the reactor, and the spongy zinc oxide-supported catalyst is evenly arranged in parallel with the UV lamps, and the processing frequency of the ultrasonic components is 20kHz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com