Fabricated building wallboard production mold with high production efficiency

A production efficiency and assembly technology, applied in the direction of molds, mold auxiliary parts, etc., can solve the problems of inability to adjust the mold size, mass production of wall panels that are not suitable for various sizes, and increase the cost of molds, so as to improve production efficiency, The effect of reducing movement resistance and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

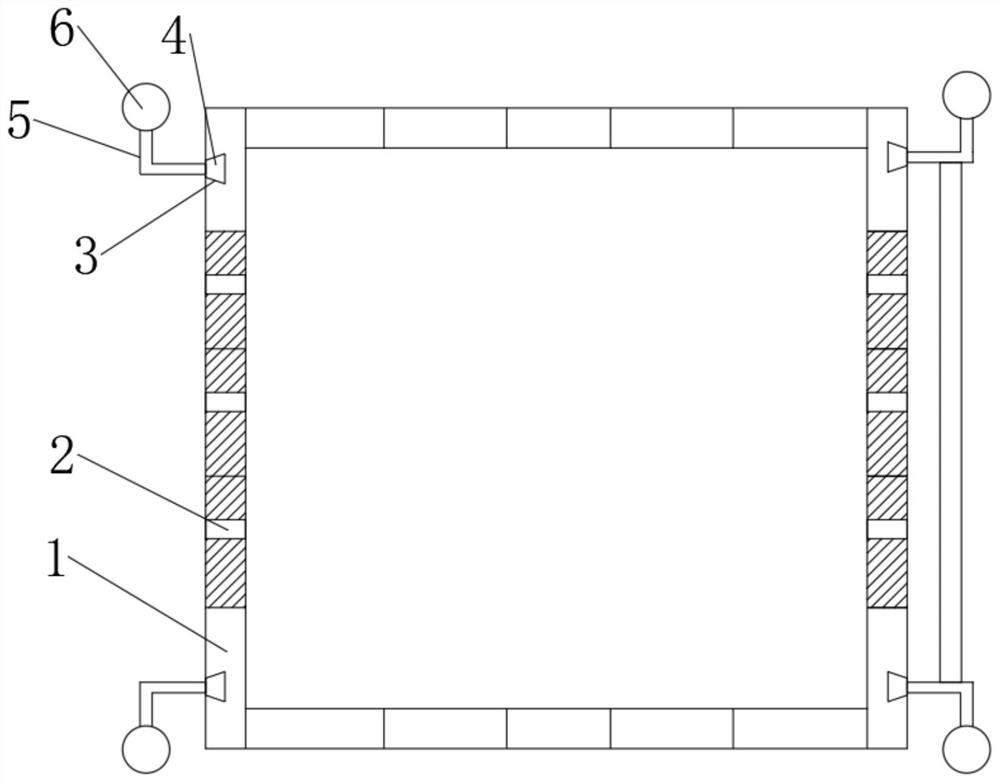

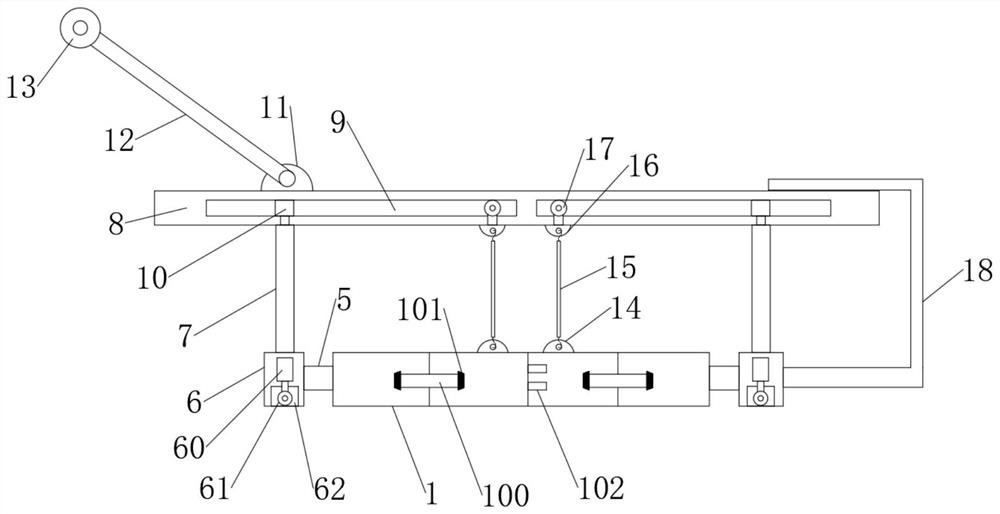

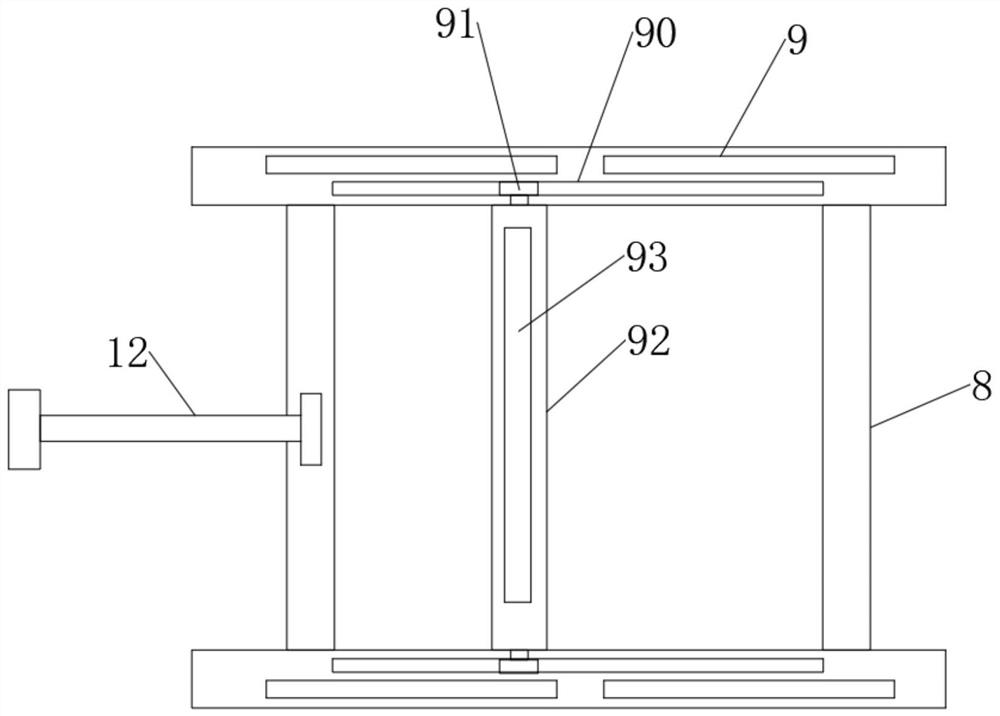

[0027] Such as Figure 1-6 As shown, a mold for the production of assembled building wall panels with high production efficiency includes a splicing plate 1, and the splicing plate 1 is provided with through steel holes 2, and the two sides of the splicing plate 1 are provided with matching holes 1000, An insertion rod 100 is arranged in the matching hole 1000, and the splicing plate 1 forms a mold frame through the insertion rod 100, and a matching groove 3 is arranged on the splicing plate 1 at the edge of the mold frame. Fitting block 4 is installed, and described fitting block 4 is connected with connecting frame 5, and described connecting frame 5 is provided with installation cylinder 6, and described installation cylinder 6 is distributed in the four corners of mold frame, and described installation cylinder 6 is provided with Lifting motor 60, the lifting motor 60 is connected to the roller 61, the end of the splicing plate 1 in the middle of the mold frame is provided...

Embodiment 2

[0034] This embodiment is a further improvement and limitation of embodiment 1 on the basis of embodiment 1.

[0035] An assembly-type building wall panel production mold with high production efficiency, comprising a splicing plate 1, a through-bar hole 2 is provided on the splicing plate 1, matching holes 1000 are provided on both sides of the splicing plate 1, and the matching An insertion rod 100 is arranged in the hole 1000, and the splicing plate 1 forms a mold frame through the insertion rod 100, and a matching groove 3 is arranged on the splicing plate 1 at the edge of the mold frame, and a matching groove 3 is installed in the matching groove 3. block 4, the mating block 4 is connected with the connecting frame 5, the connecting frame 5 is provided with installation cylinders 6, and the installation cylinders 6 are distributed and arranged at the four corners of the mold frame, and the installation cylinder 6 is provided with a lifting motor 60 , the lifting motor 60 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com