Double-head sheet grinding machine with shock absorption function

A grinding and functional technology, which is applied to grinding frames, machine tools suitable for grinding workpiece planes, grinding machines, etc., can solve the problems of vibration, low efficiency and affecting processing efficiency of the grinding machine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following is merely the preferred embodiment of the present invention, and the scope of protection is not limited to this embodiment, and the technical solution that belongs to the idea of the present invention should belong to the scope of the present invention. At the same time, it should be noted that these improvements and moisters should also be considered as the scope of the invention without departing from one of the modifications and moisters not departing from the principles of the invention.

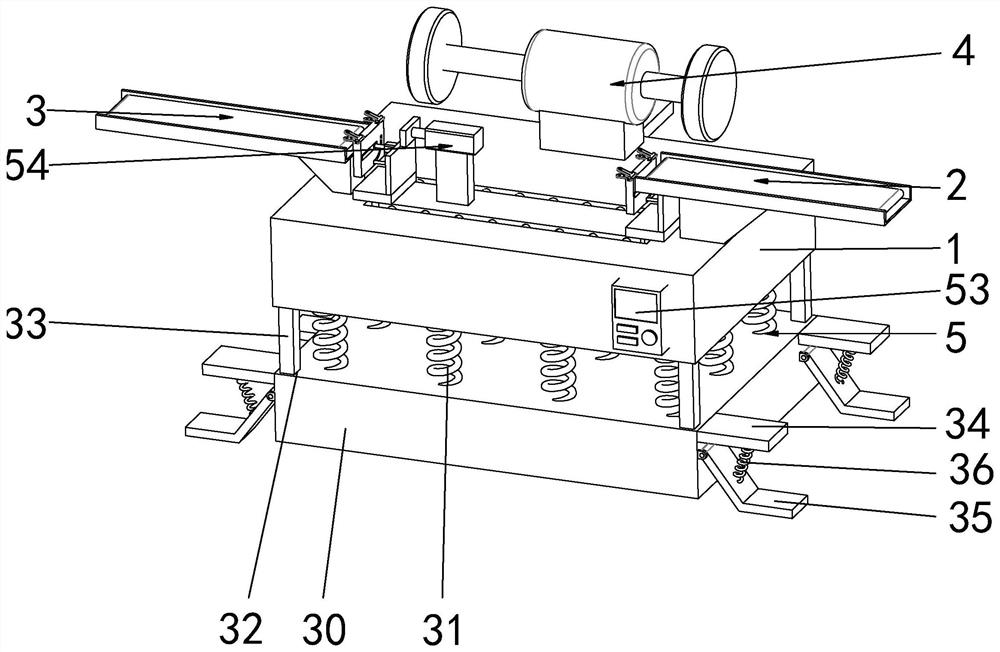

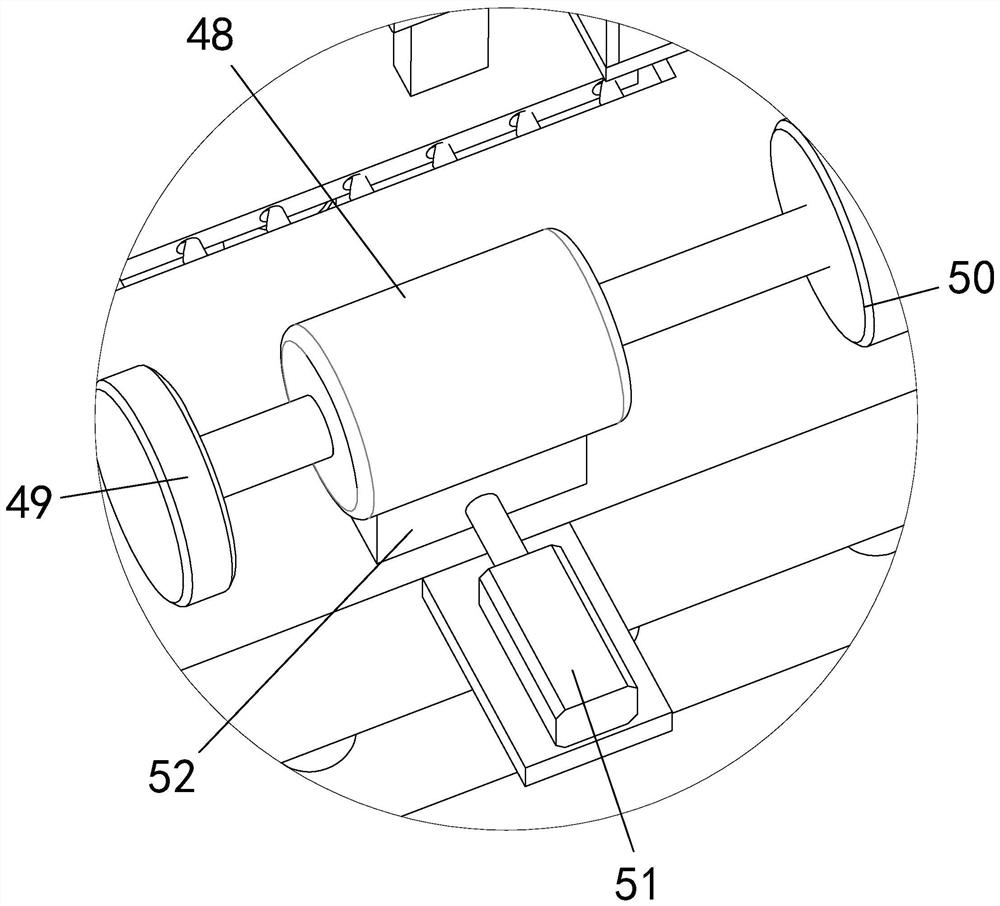

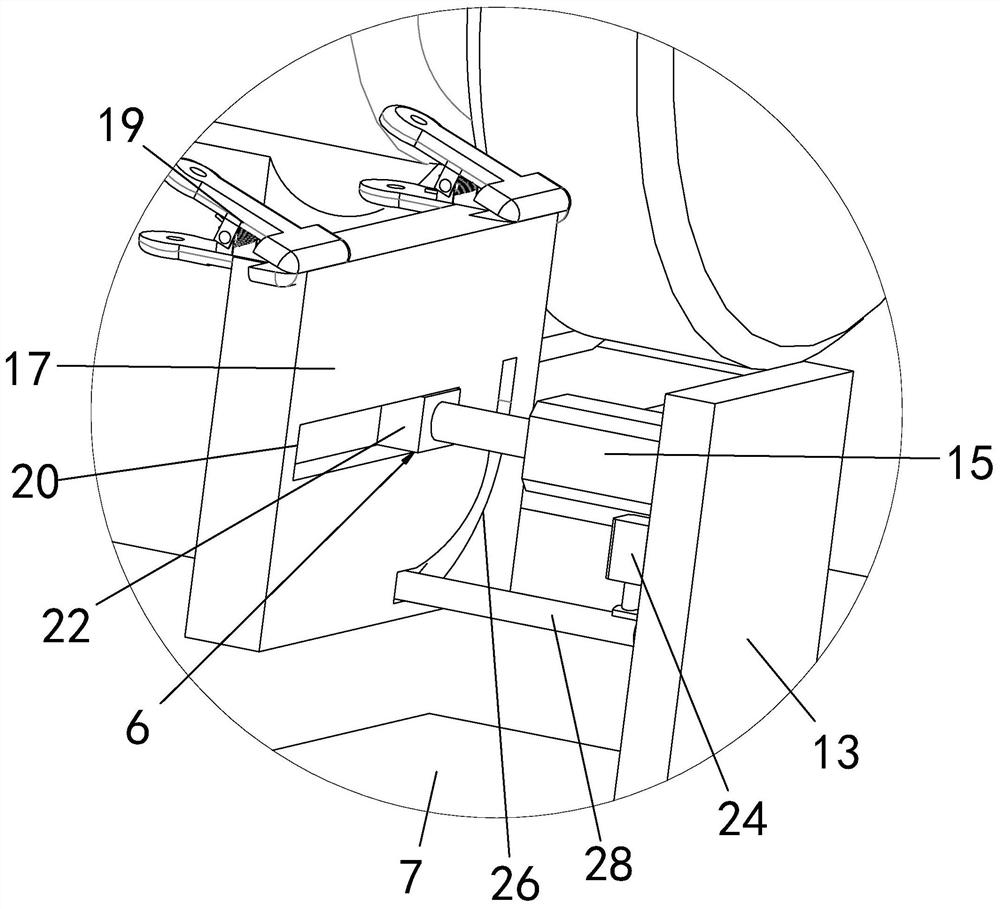

[0028] see Figure 1 to 6 A double-head mill having a shock absorbing function comprising a base 1, a transfer assembly one 2, a transfer assembly 54, further comprising a processing apparatus 4 disposed on the base 1, provided in the lower end of the base 1. The damping device 5 is disposed on the base 1, and the plurality of rubber strips are disposed onto the transfer assembly one 2, and the upper and lower device 6 includes a placement table 7 and a placement table ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com