Chain type pizza oven

A pizza oven, chain technology, used in kitchen utensils, home utensils, roasters/barbecue grids, etc., can solve the problems of troublesome assembly, high cost of gear processing, and high heat loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

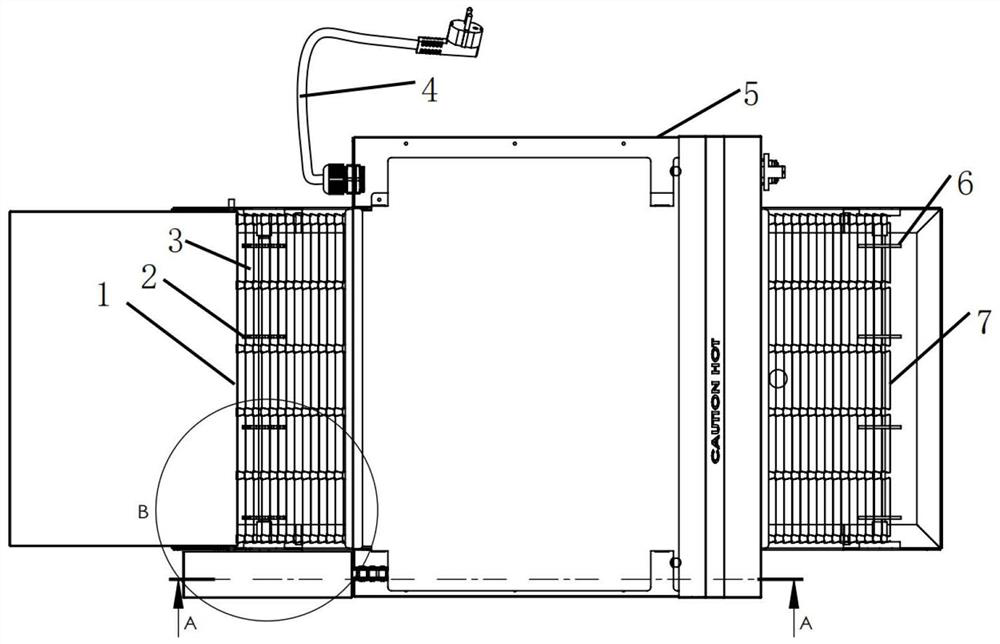

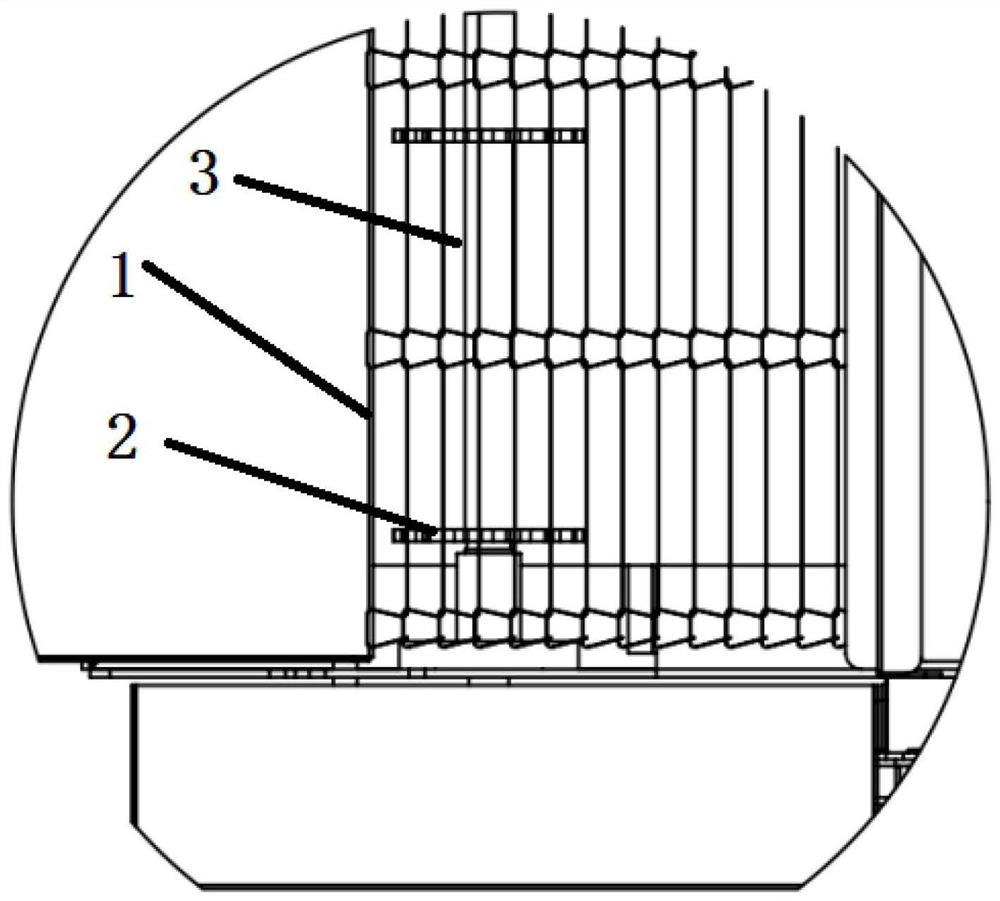

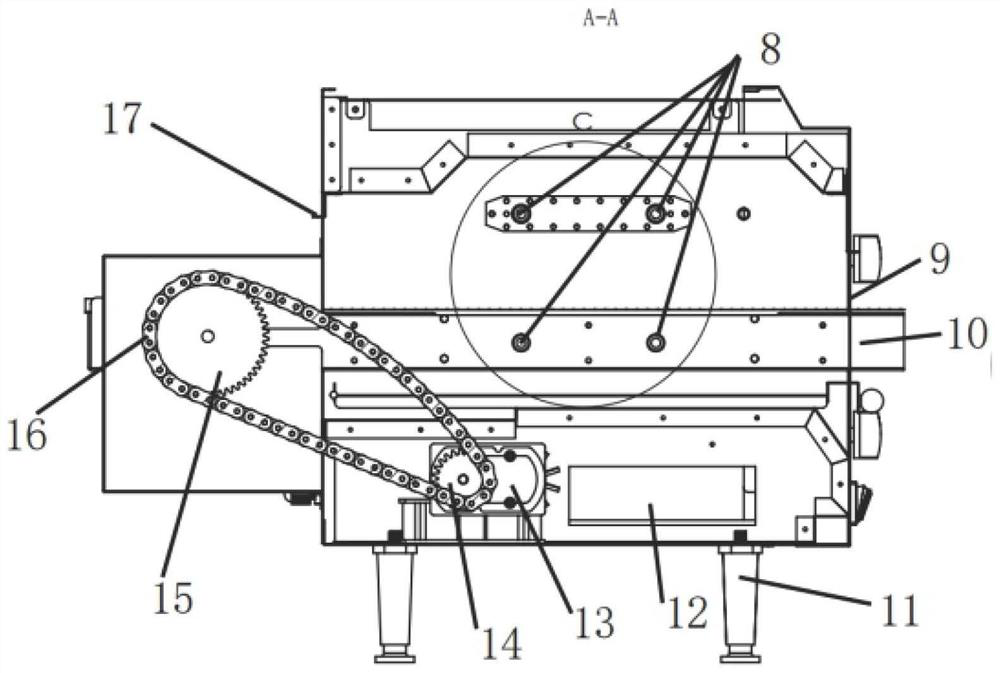

[0023] Such as Figure 1-8 As shown, a chain type pizza oven includes a box body 5, and the box body 5 is provided with a horizontally placed chain conveyor frame 10, and the chain conveyor frame 10 is equipped with a chain mesh that can circulate in a horizontal position. 1. Because the chain net 1 can move continuously, users can continuously put in food for processing according to needs, so as to meet the requirements of large processing volume, fast processing speed and continuous food output. The drive shaft 3 is installed at the rear end of the chain net transmission frame 10, and a group of plum blossom gears 2 are arranged on the drive shaft 3, and one end of the chain net 1 is set on the said plum blossom gear 2, and the other end of the chain net 1 is covered with On the driven wheel 6, the driven wheel 6 is installed on the driven shaft 7, and one end of the drive shaft 3 extends to the outside of the chain conveyor frame 10, and a driven gear 15 is installed thereo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com