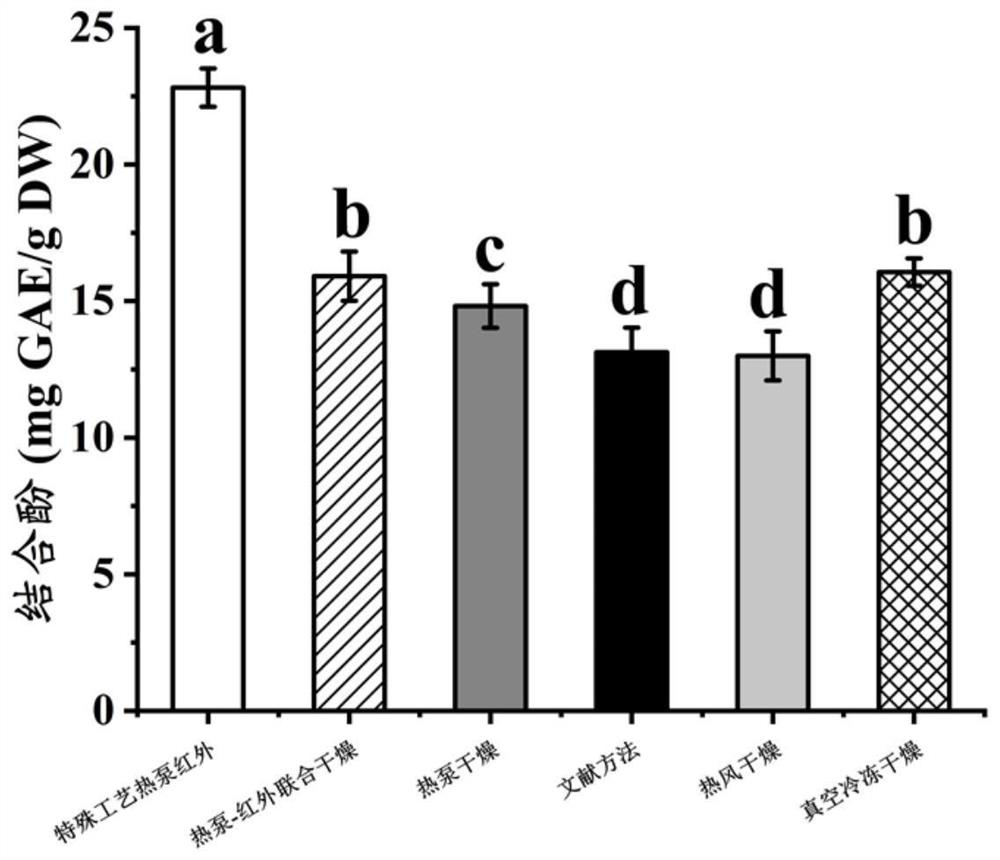

Intermittent drying process for improving bonded phenol in litchi pomace and application thereof

A drying process and litchi fruit technology, applied in the fields of application, food drying, drying solid materials, etc., can solve the problems such as the decrease of the mass fraction of bound phenols and the discussion of changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

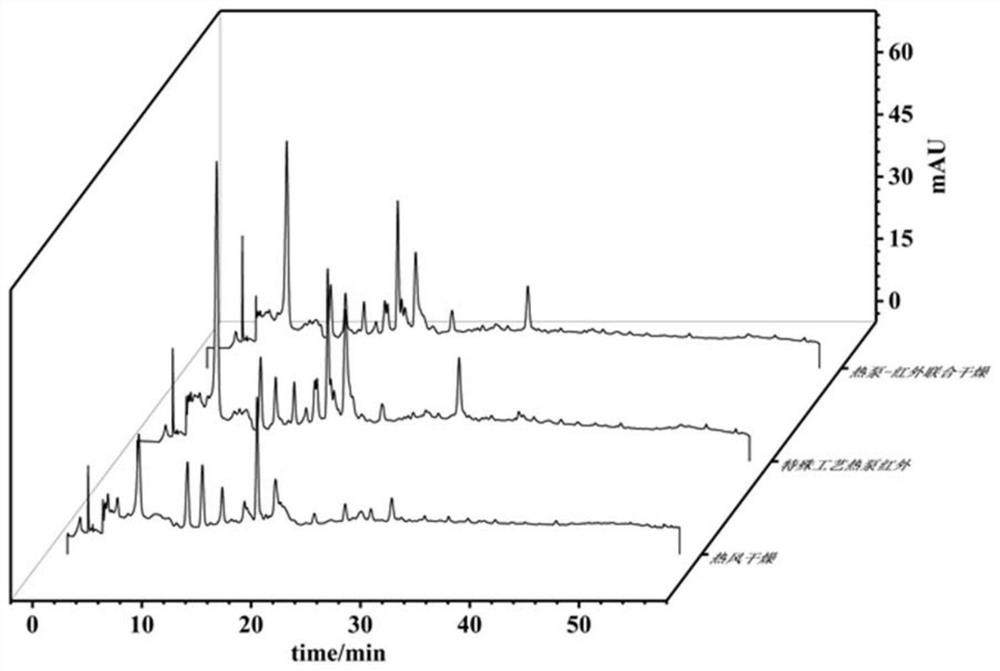

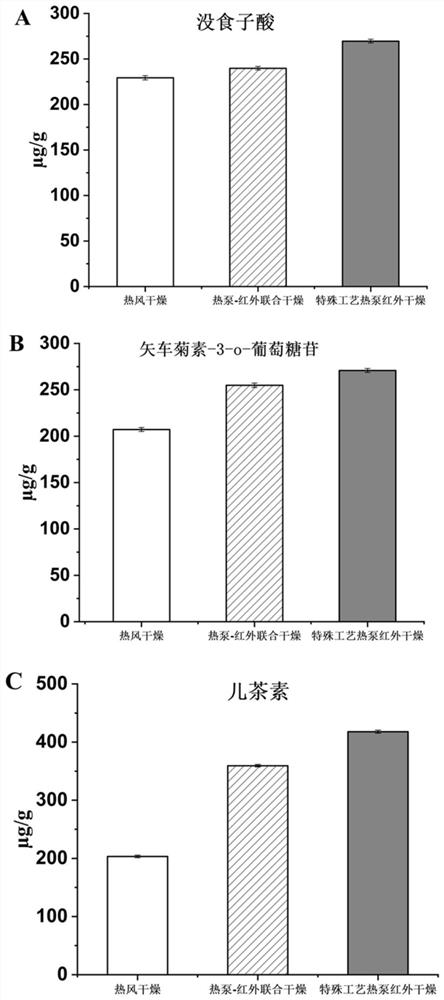

Method used

Image

Examples

Embodiment 1

[0038] Take 500g of lychee pomace and dry it with a specially controlled intermittent process-heat pump infrared combined drying. The specific steps are as follows:

[0039] S1: peeling and removing the pits of fresh lychees, then washing the obtained lychee pulp, then squeezing and centrifuging the lychee pulp to obtain lychee pomace;

[0040] S2: ① Dry the fresh lychee pomace first with heat pump for 1 hour, heat pump combined with infrared drying for 4 hours, and stop for 2 hours; 25h, excluding downtime); Among them, the heat pump temperature is 50°C, the heat pump wind speed is 1.0m / s, the far-infrared radiation power is 1000w, and the distance from the radiation plate is 10cm (the heat pump combined with infrared dryer is in the heat pump dryer WRH-100TB ( Guangdong Weierxin Industrial Co., Ltd.) The left and right walls of the drying room are laid with far-infrared radiation heating panels (customized by Yancheng Gemei Electric Heating Technology Co., Ltd., emissivity 0...

Embodiment 2

[0044] Take 500g of lychee pomace and dry it with a specially controlled intermittent process-heat pump infrared combined drying. The specific steps are as follows:

[0045] S1: peeling and removing the pits of fresh lychees, then washing the obtained lychee pulp, then squeezing and centrifuging the lychee pulp to obtain lychee pomace;

[0046] S2: ① Dry the fresh lychee pomace first with heat pump for 1 hour, heat pump combined with infrared drying for 4 hours, and stop for 2 hours; 25h, excluding downtime); Among them, the heat pump temperature is 60°C, the heat pump wind speed is 1.5m / s, the far-infrared radiation power is 2000w, and the distance from the radiation plate is 10cm (the heat pump combined with infrared dryer is in the heat pump dryer WRH-100TB ( Guangdong Weierxin Industrial Co., Ltd.) The left and right walls of the drying room are laid with far-infrared radiation heating panels (customized by Yancheng Gemei Electric Heating Technology Co., Ltd., emissivity 0.9...

Embodiment 3

[0050] Take 500g of lychee pomace and dry it with a specially controlled intermittent process-heat pump infrared combined drying. The specific steps are as follows:

[0051] S1: peeling and removing the pits of fresh lychees, then washing the obtained lychee pulp, then squeezing and centrifuging the lychee pulp to obtain lychee pomace;

[0052] S2: ① Dry the fresh lychee pomace first with heat pump for 1 hour, heat pump combined with infrared drying for 4 hours, and stop for 2 hours; 25h, excluding downtime); Among them, the heat pump temperature is 90°C, the heat pump wind speed is 2.0m / s, the far-infrared radiation power is 3000w, and the distance from the radiation plate is 10cm (the heat pump combined with infrared dryer is in the heat pump dryer WRH-100TB ( Guangdong Weierxin Industrial Co., Ltd.) The left and right walls of the drying room are laid with far-infrared radiation heating panels (customized by Yancheng Gemei Electric Heating Technology Co., Ltd., emissivity 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com