Differential speed stubble breaking type belt cleaning device

A differential speed stubble breaking and cleaning device technology, applied in agricultural machinery and implements, agriculture, cutters, etc., can solve the problems of poor cleaning effect of seed belts, affecting sowing operations, and deep soil depth, and achieves improved no-tillage. Sowing quality, reducing soil erosion, and small soil-moving amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

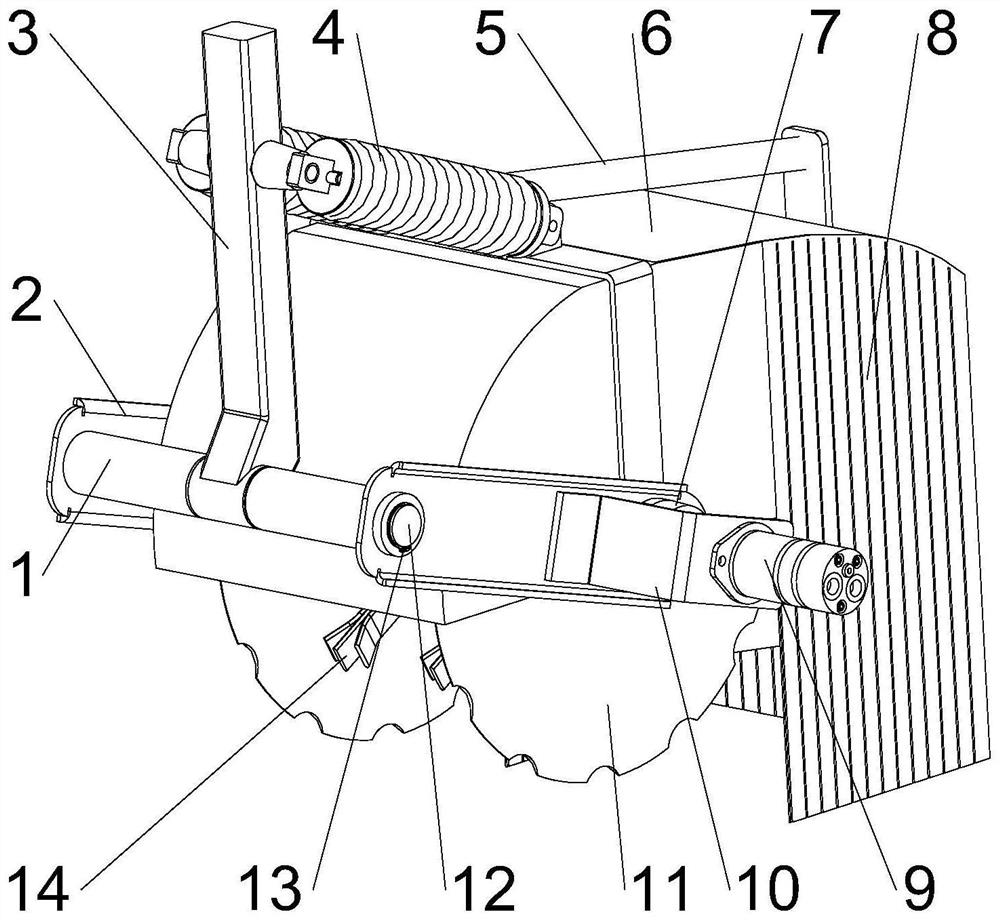

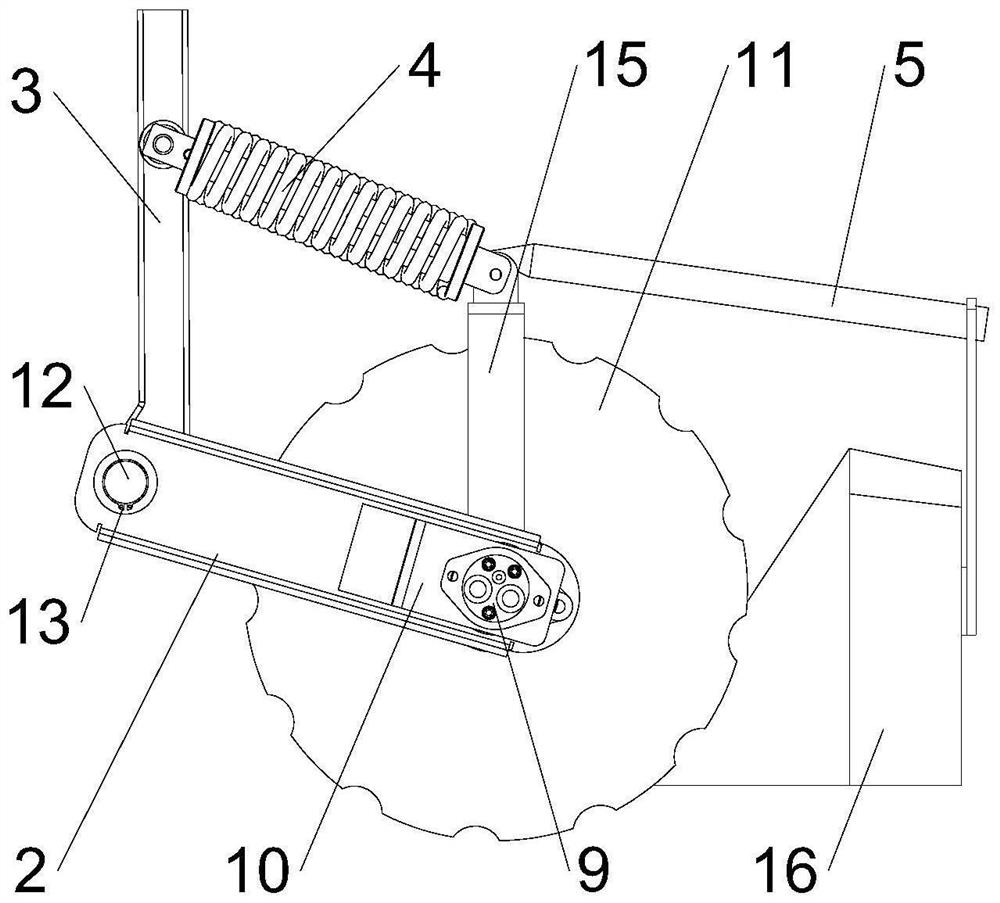

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0023] like Figures 1~3 The illustrated embodiment of the present invention includes: a side mounting frame bushing 1, a side mounting frame 2, a vertical mounting frame 3, a profiling spring 4, a crop divider mounting frame 5, a coupling 7, a power source 9, a power source The installation frame 10, the installation frame central shaft 12, the shaft end elastic retaining ring 13, the cover installation frame 15, the crop divider 16, the bearing with seat 18 and the stubble cutter group are composed; the vertical installation frame 3 is arranged on the central shaft of the installation frame The center of the axial direction of 12, from the center of the central axis 12 of the mounting frame to the two ends, are symmetrically provided with a side mounting frame bushing 1, a side mounting frame 2 and an elastic retaining ring 13 at the shaft end; The two end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com