Thin film energy reducer suitable for high-power beam current

A high-power, energy-degrading technology, applied in the direction of magnetic resonance accelerators, accelerators, electrical components, etc., can solve the problems of energy-degrading devices that have a large thermal load and cannot work normally, and achieve small energy dissipation, small changes in beam divergence angle, and The effect of small emissivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 Embodiment 1 Embodiment 2

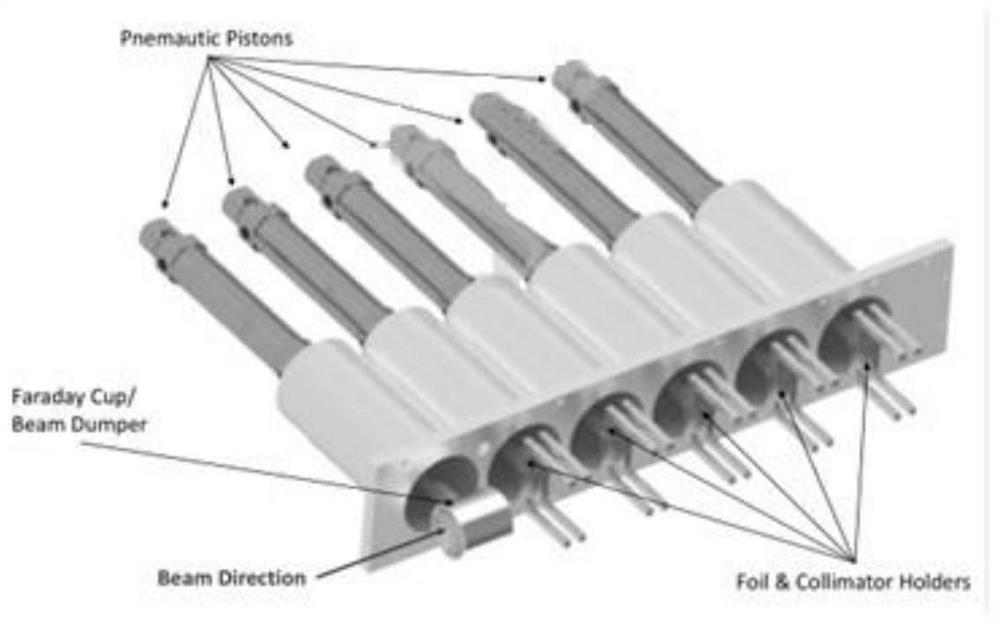

[0043] The above is the first embodiment of a thin-film energy degrader suitable for high-power beam provided by the embodiment of the present application, and the following is an embodiment of a thin-film energy degrader suitable for high-power beam provided by the embodiment of the present application Second, please refer to Figure 3-Figure 8 :

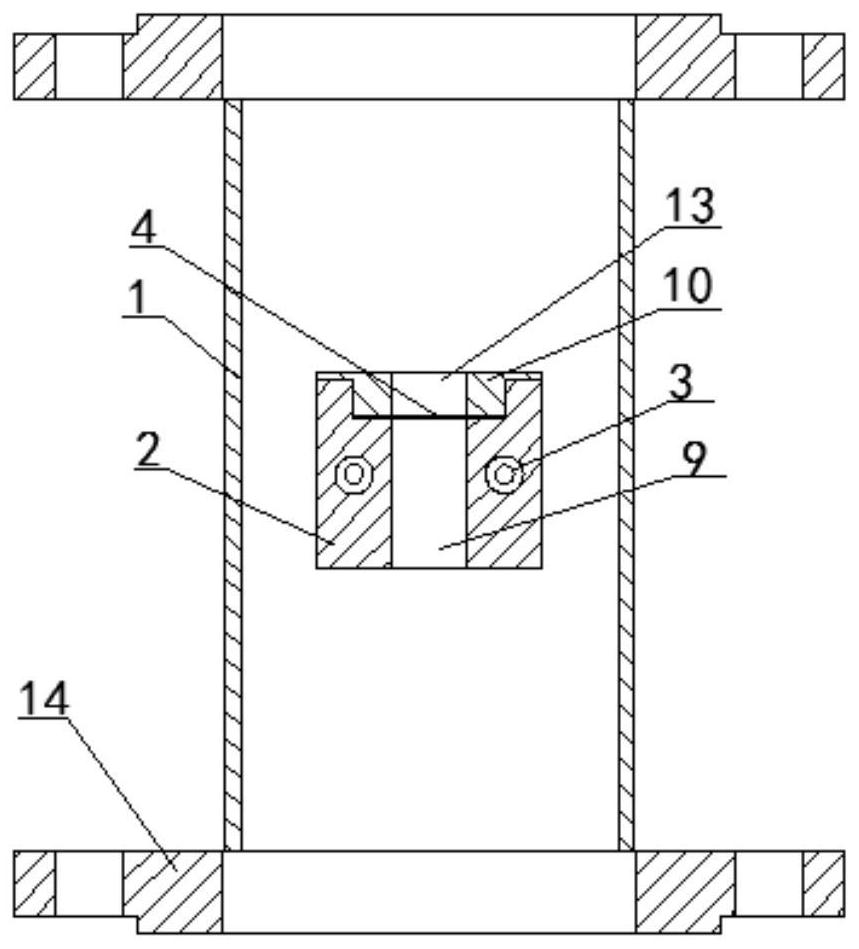

[0044] In this embodiment, a thin-film energy degrader suitable for high-power beams includes a vacuum tube 1, a hollow copper base 2 located inside the vacuum tube 1, and a cooling cooling device installed inside the copper base 2. A water device 3, a film 4 arranged inside the copper base 2, and a support base 5 arranged on the wall of the vacuum tube 1 to support and fix the copper base 2, the copper base 2 and the vacuum tube 1 coaxial setting.

[0045] Wherein, the structure of the support base 5 can be a cuboid structure, a cylinder structure or other structures that can facilitate the support and fixation, and the specific...

Embodiment 3

[0057] The present invention is applied to the spent fuel radiation extraction experiment based on CS-30 cyclotron α beam flow, the radiation extraction experiment needs to lead the accelerator to the energy of α beam flow with energy of 30MeV, current intensity of 20μA, and emittance of 35mm.mrad Reduced to 4-7MeV, the inventor has specifically designed each part of the energy reducer of the present invention under this range:

[0058] In this embodiment, the wall thickness of the vacuum tube 1 is 10 mm, the outer radius is 80 mm, and the inner radius is 75 mm. The copper base 2 is a cylindrical structure with an outer radius of 35 mm and a height of 20 mm. The radius of the upper hollow structure of the "shaped hollow structure 9 is 20 mm, the radius of the upper hollow structure is 10 mm, the height of the upper hollow structure is 4 mm, the radius of the diamond film is 20 mm, and the thickness is 209 μm. The radius of the upper cover 11 of the screw gland 10 is 35 mm , Th...

experiment example

[0062] The inventors used aluminum thin films and copper thin films commonly used in this field, and diamond thin films as the thin film materials in the energy reducer respectively, and carried out α beam emittance and scattering angle change simulation calculations, as well as temperature change simulation calculations, to verify that the diamond thin film is based on Invention of the most suitable film material for energy reducers;

[0063] According to the initial beam parameters drawn by the CS-30 cyclotron, the initial beam is designed using the G4beamline program. The physical module uses the low-energy numerical simulation QGSP_BERT. The initial beam is a Gaussian distribution beam, which is similar to the actual beam drawn by the accelerator; The initial beam energy is 30MeV, the root mean square σ of the initial beam x direction X =1.64mm, σ X′ = 0.73 mrad.

[0064] Using the SRIM program to calculate the thickness of the aluminum film, copper film and diamond film...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com